Power generation apparatus and control method thereof

A power generation device and control chip technology, which is applied in the direction of electromechanical devices, cooling/ventilation devices, and control/drive circuits, etc., can solve the problems of generator energy consumption, failure, etc., to achieve the improvement of electric energy and energy saving, and reduce the reaction force Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

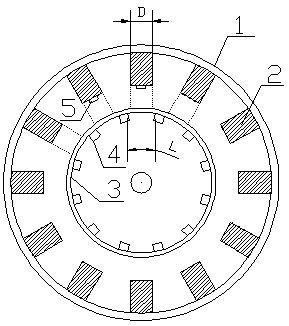

[0047] As shown in 1, a power generating device includes a winding base 1, a winding 2 disposed on the winding base 1, a magnet base 3, a magnet 4 disposed on the magnet base 3, and a magnet 4 disposed on the winding 2 for A position sensor 5 and a control circuit that perceives the position of the magnet 4, wherein: the diameter D of the winding 2 is less than the distance L between adjacent magnets 4; When the magnet 4 and the winding 2 move relatively, the control circuit conducts the winding 2 when the winding 2 is located between two adjacent magnets 4, and controls the discharge of the winding 2 to the outside. The position during discharge is as follows: figure 2 shown.

[0048] Specifically, the distance L is the arc length between two adjacent magnets.

[0049] It should be noted, figure 2The discharge of the middle winding 2 generates an induced magnetic field. Since the induced magnetic field is far away from the magnet 4 and the magnetic poles of the magnetic f...

Embodiment 2

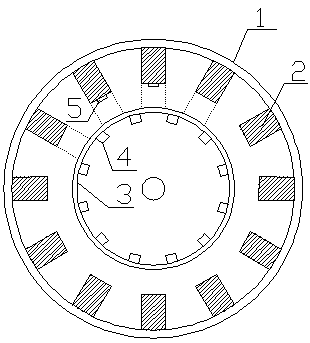

[0054] Such as image 3 As shown, on the basis of the first embodiment, the magnets 4 in this implementation are evenly arranged, and the number of the magnets 4 is six. When the magnet 4 and the winding 2 move relatively, the control circuit conducts the winding 2 and controls the winding 2 to discharge to the outside when the winding 2 is located between two adjacent magnets 4 .

Embodiment 3

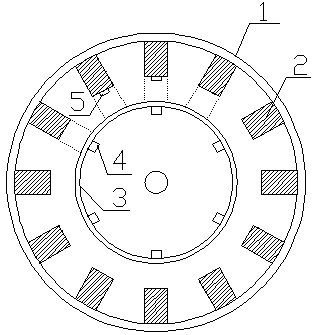

[0056] Such as Figure 4 As shown, on the basis of Embodiments 1 and 2, the magnets 4 in this implementation are arranged non-uniformly, and the number of magnets 4 is two.

[0057] At this time, each winding 2 is provided with a position sensor 5 .

[0058] When the magnet 4 and the winding 2 move relatively, the control circuit conducts the winding 2 and controls the corresponding winding 2 to discharge to the outside when the winding 2 is located between two adjacent magnets 4 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com