A detection tool for the integral delivery module of a steam turbine

A technology for detection tools and steam turbines, which is applied in the direction of measuring devices, mechanical devices, instruments, etc., can solve the problems of unguaranteed accuracy and efficiency of on-site assembly detection, achieve significant economic and social benefits, and improve assembly accuracy and consistency Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

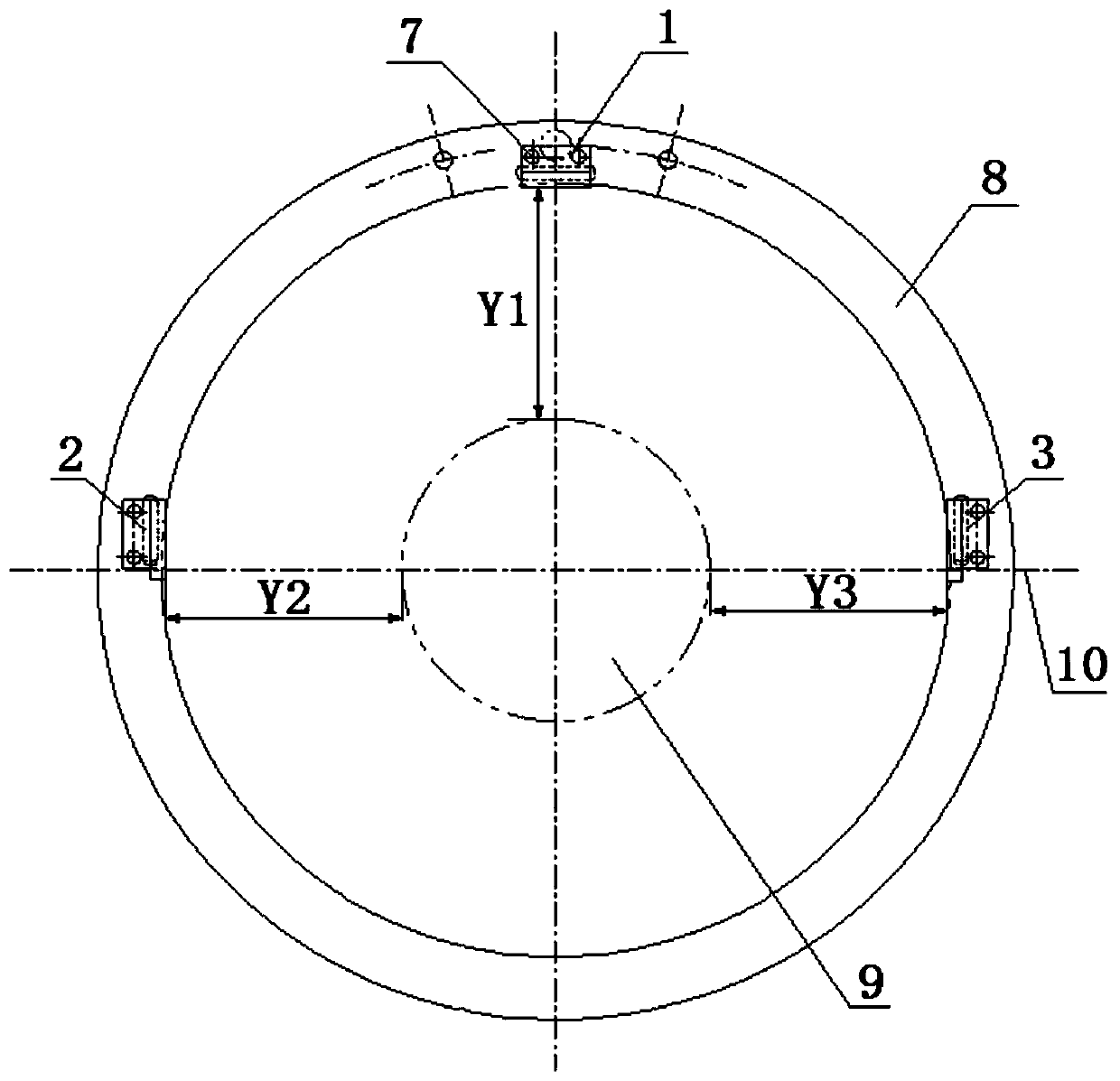

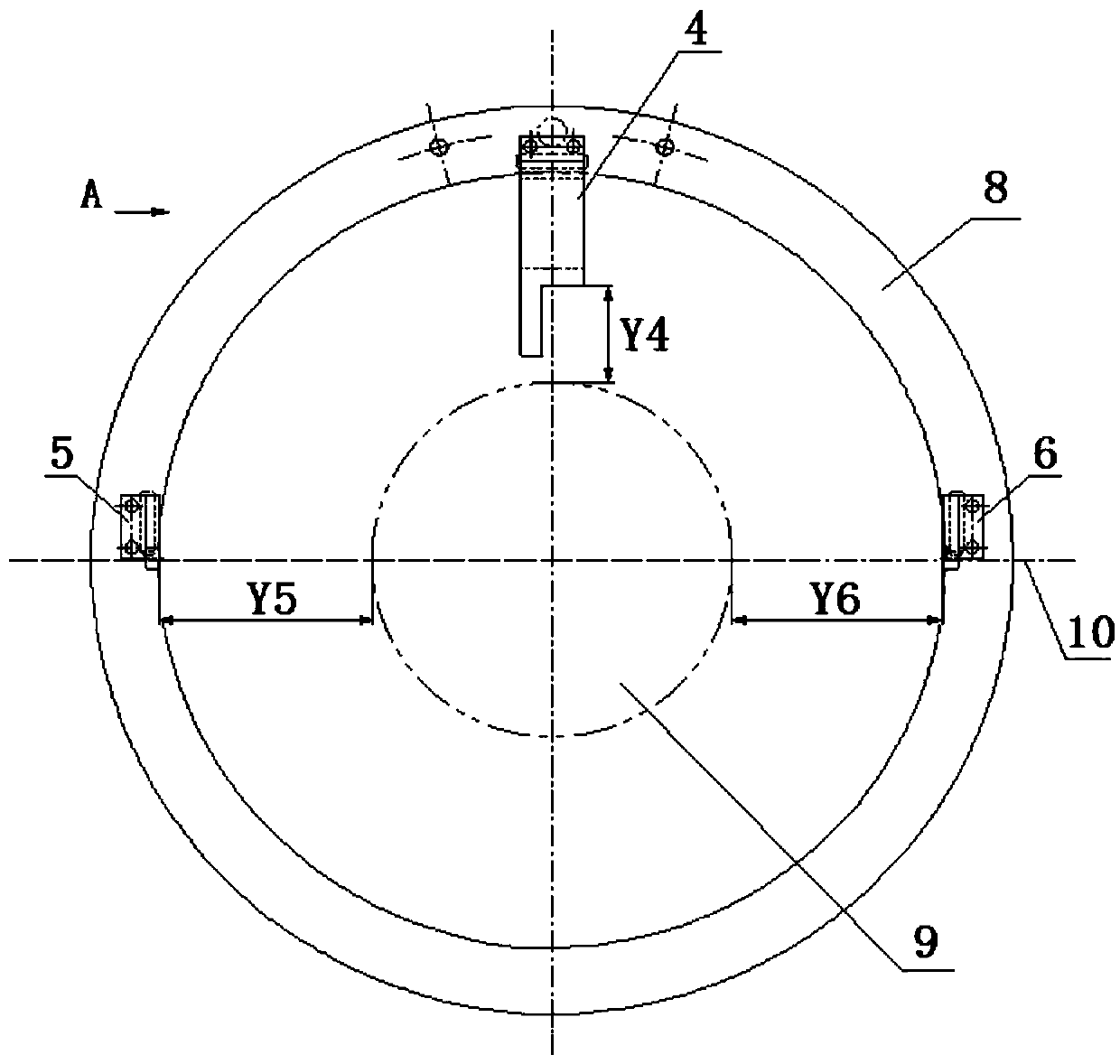

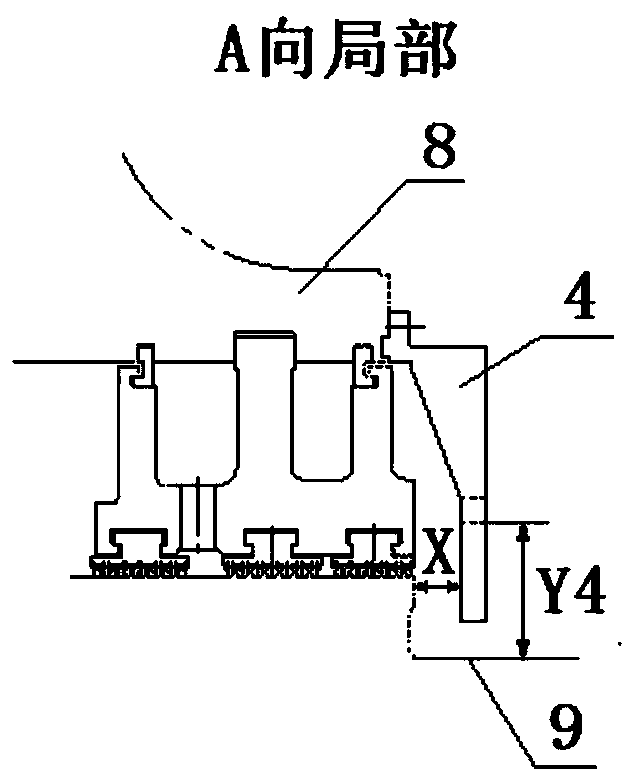

[0027] Such as Figure 1 to Figure 9 As shown, a testing tool for the overall delivery module of a steam turbine includes a measuring tool; the measuring tool includes a mounting part 11 and a measuring part 12 perpendicular to each other, forming an L shape; there is a protruding notch 13 on the back of the mounting part 11 , and positioned on the end wall of the outer cylinder 8 through the seam 13; the seam 13 is matched with the concave groove on the end wall of the outer cylinder 8, and the matching accuracy is 0.05 mm to 0.15 mm. The outer surface of the measuring part 12 is a measuring surface 14 . The measuring tools are divided into three measuring tools on the turbine side and three measuring tools on the motor side. There are installation holes 15 on the installation part 11 of the measuring tool, and are fixed together with the outer cylinder 8 by bolts 7 .

[0028] The turbine-side measuring instruments include turbine-side measuring instruments I1-III3; the tur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com