Pin shaft and connecting structure and assembling method thereof

A connection structure and pin shaft technology, which is applied in the direction of engine components, bolts, engine lubrication, etc., can solve the problems of increased wear of pin shafts, achieve the effect of reducing friction and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

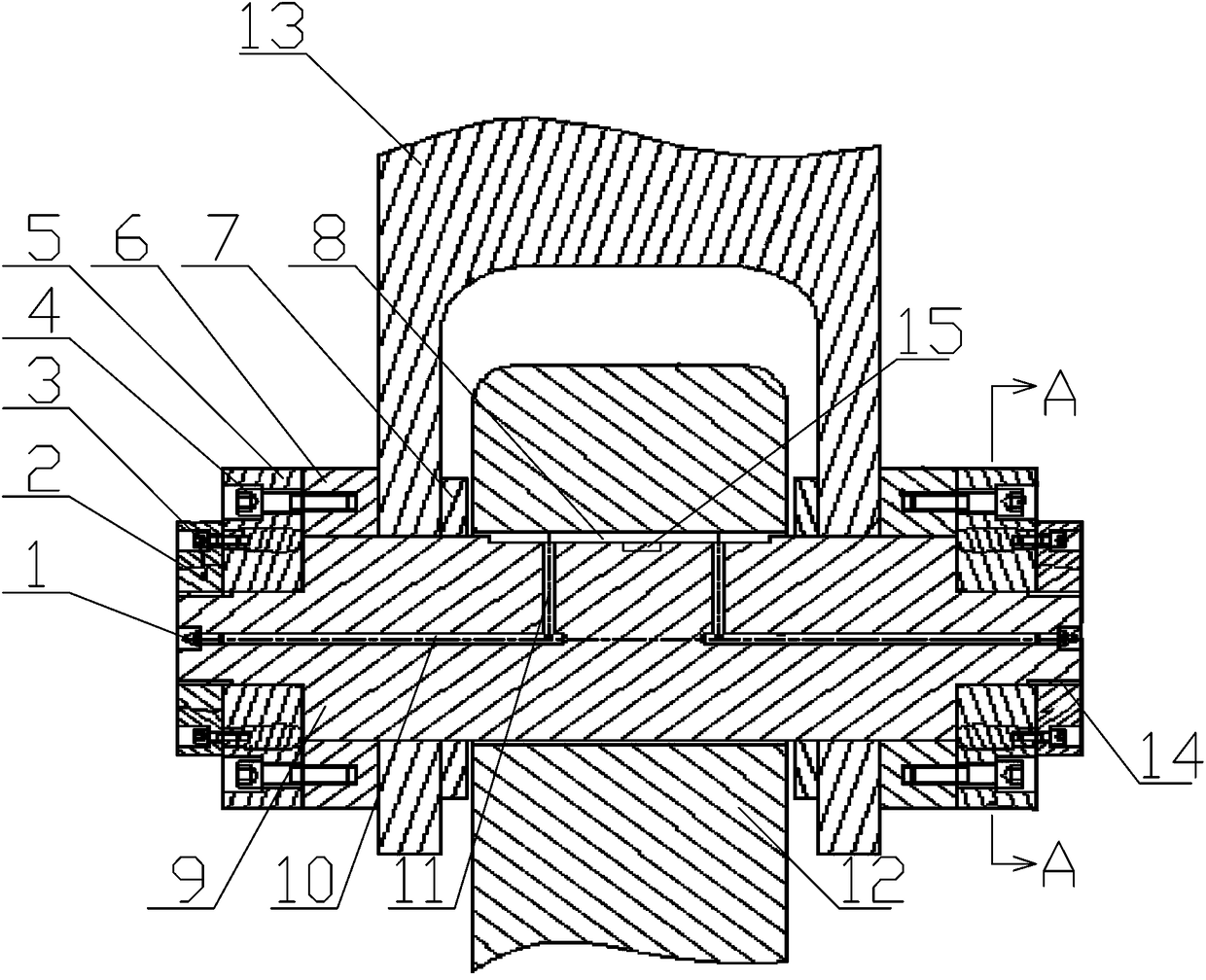

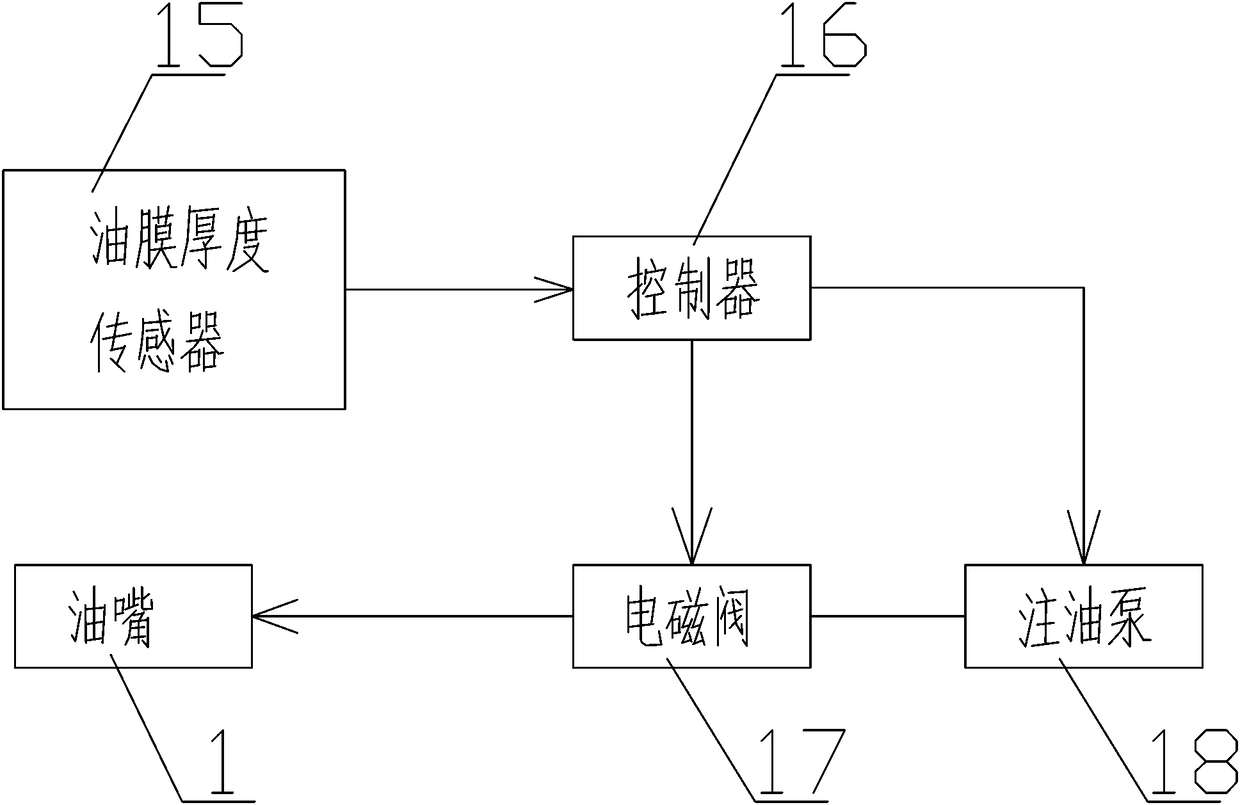

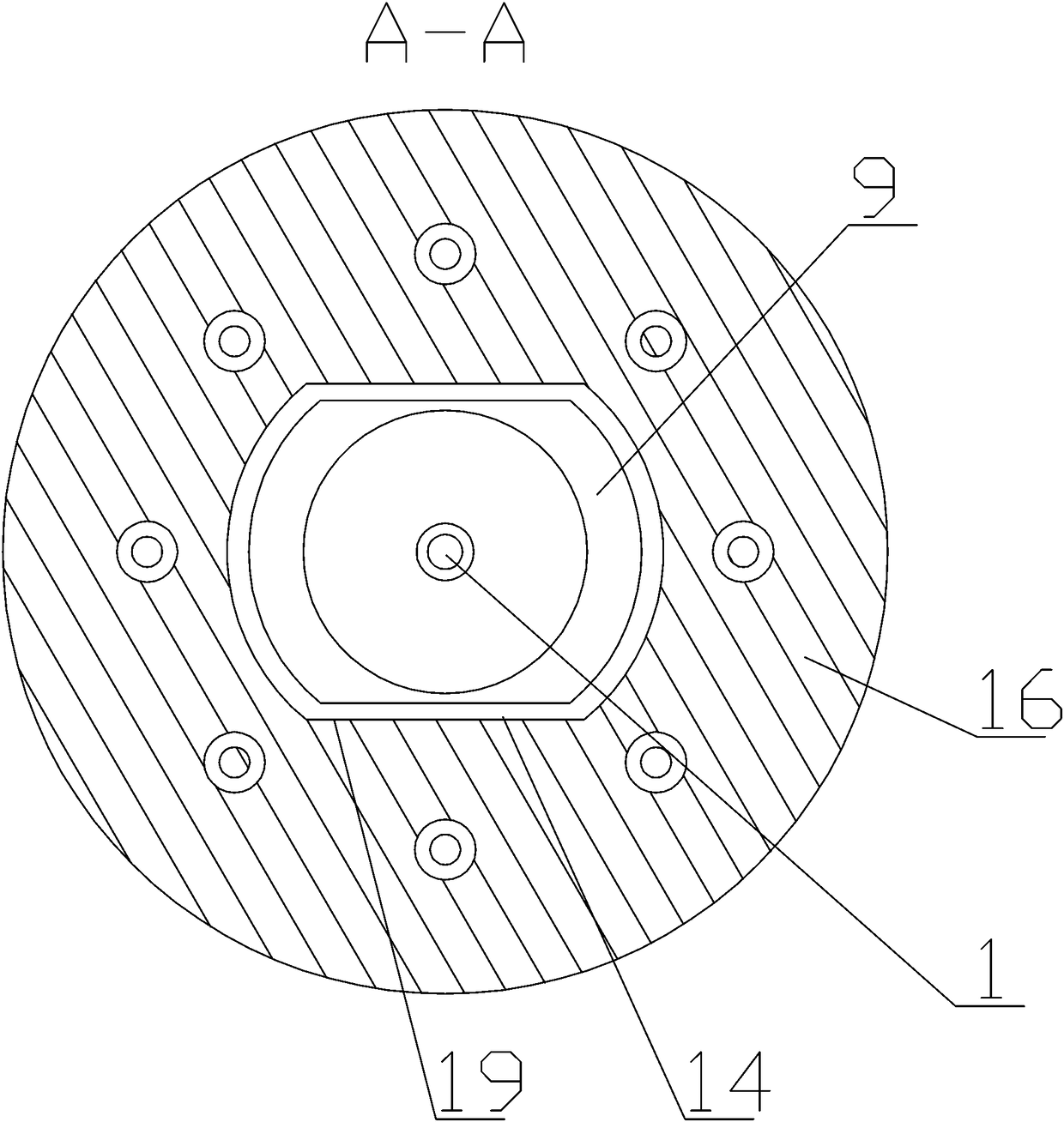

[0036] Such as Figure 1-3 Shown, a kind of pin shaft and its connecting structure, it comprises pin shaft body 9, and described pin shaft body 9 passes through first pin shaft connecting piece 13 and second pin shaft connecting piece 12, on both sides of pin shaft body 9 The pin shaft pressing plate 5 for axially limiting the pin shaft body 9 is mounted symmetrically on the end, the pin shaft pressing plate 5 is installed on the fixing plate 6 through the first screw 4, and the outer end surface of the pin shaft pressing plate 5 is provided with Pin shaft fixing nuts 2 are installed at both ends of the pin shaft body 9 . By adopting the above-mentioned pin shaft and its connection structure, it can be used in occasions that bear a large axial force, and the lubricating oil filling device can effectively reduce the gap between the pin shaft body 9 and the second pin shaft connecting piece 12. The friction force between them can be automatically lubricated through the automati...

Embodiment 2

[0046] The assembly method of any one of the described pin shaft and its connecting structure, it comprises the following steps:

[0047] Step1: Install the oil film thickness sensor 15 at the oil groove gap 8 on the pin body 9;

[0048] Step2: Pass the pin body 9 through the first pin connector 13, the limit plate 7 and the second pin connector 12 in sequence;

[0049]Step3: install the pin pressing plate 5 at both ends of the pin body 9, and install the pin pressing plate 5 on the fixing plate 6 through the first screw 4;

[0050] Step4: install the pin shaft fixing nut 2 on the two threaded sections 14 of the pin shaft body 9, and press and fix the pin shaft pressing plate 5 through the pin shaft fixing nut 2;

[0051] Step5: Fix and install the second screw 3 on the outer end surface of the pin fixing nut 2, and fix the pin fixing nut 2 on the outer end surface of the pin pressing plate 5 through the second screw 3;

[0052] Step6: Install the oil nozzle 1 at the axial h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com