Pressure loading device and pressure loading test method for rubber sealing ring

A technology of rubber sealing ring and loading device, which is applied to measuring device, using stable tension/pressure test material strength, instrument, etc., can solve the problems of inability to simulate the deformation of rubber sealing ring, low accuracy, etc., and achieve easy disassembly. Rubber sealing ring, good accuracy, high precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

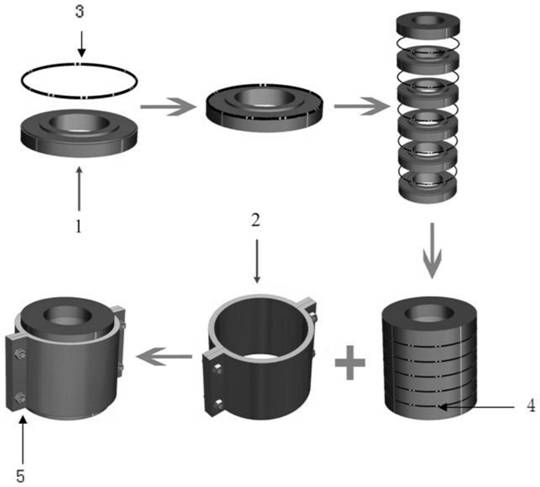

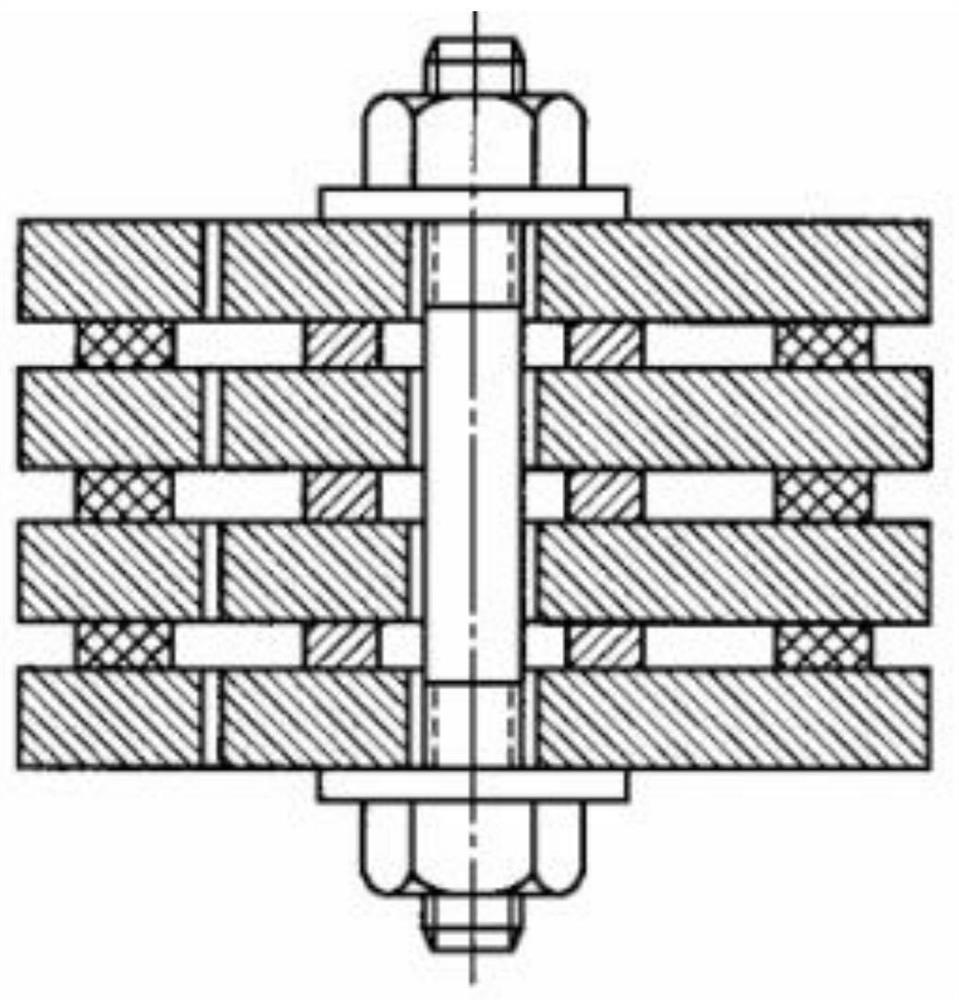

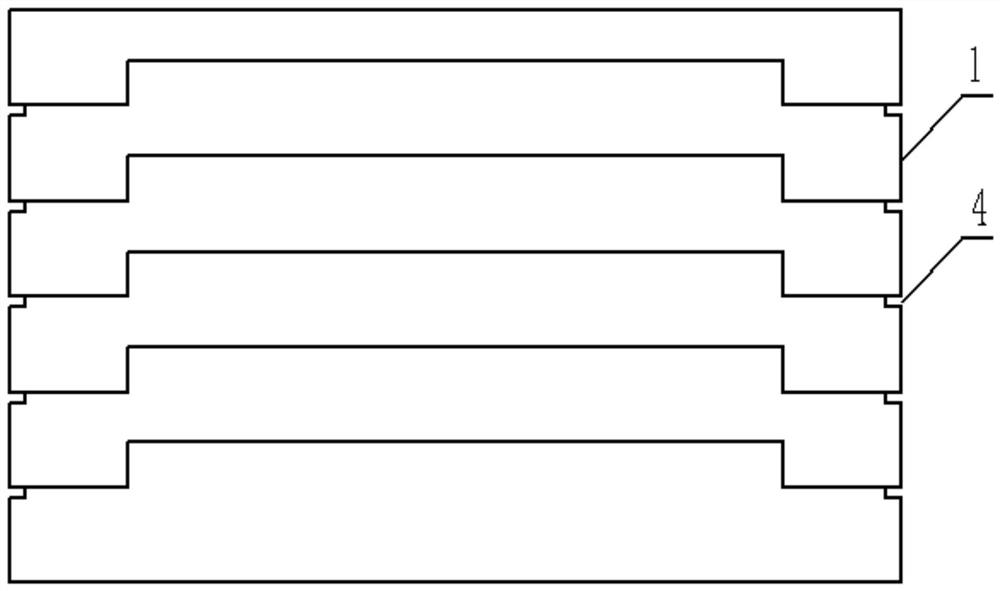

[0035] Rubber sealing ring pressure loading device such as figure 2As shown, it includes a metal ring 1 and a split sleeve 2 sleeved on the metal ring 1, and the split sleeve 2 and the metal ring 1 are matched in a manner that the minimum gap is equal to zero; on the side of the metal ring 1 The wall is provided with an annular groove 4, and the width of the annular groove 4 is 95%-110% of the initial height of the rubber sealing ring (such as when the initial height of the rubber sealing ring is 3.5mm, the width of the annular groove 4 is processed to be 3.33-3.85mm), The depth of the ring groove 4 is equal to the height of the rubber sealing ring when it is under pressure during storage with the bomb (such as when the height of the rubber sealing ring is 2.6mm when it is stored with the bomb and the height is 2.6mm, the depth of the ring groove 4 is 2.6mm, this depth That is, the specified height reached by the rubber sealing ring test piece 3 after pressure loading), and t...

Embodiment 2

[0051] With reference to embodiment 1, wherein, the annular groove adopts arc groove, and the depth of arc groove is 2.6mm, and its metal ring 1 and annular groove 4 are as Figure 5 shown.

Embodiment 3

[0053] Referring to Example 1, wherein the ring groove is provided on the outer wall of the integrally formed metal ring, the metal ring 1 and the ring groove 4 are as Figure 5 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| deformation rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com