Quick die change device and foam molding machine with quick die change device

A molding machine and fast technology, applied in the field of mechanical equipment, can solve the problems of inability to adopt the first assembly method, difficult to assemble the mold support plate, and inability to assemble

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

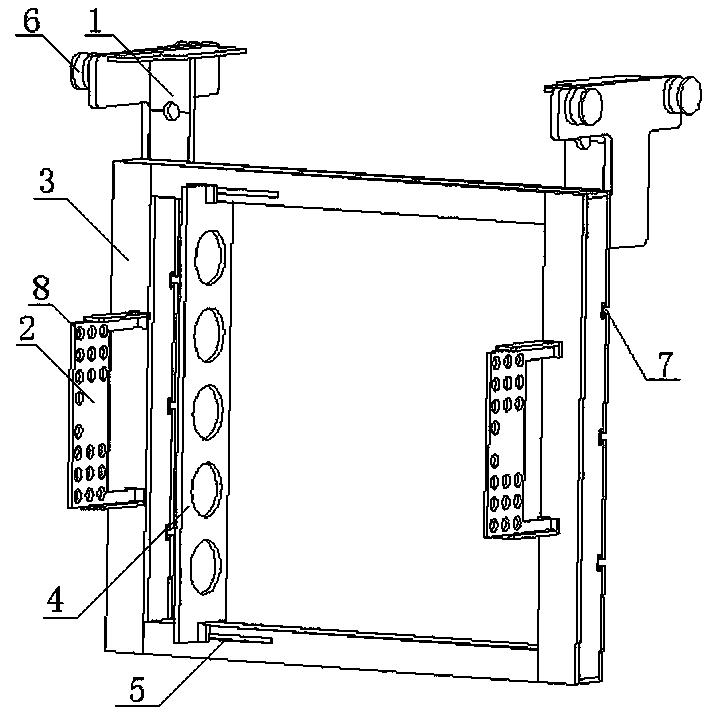

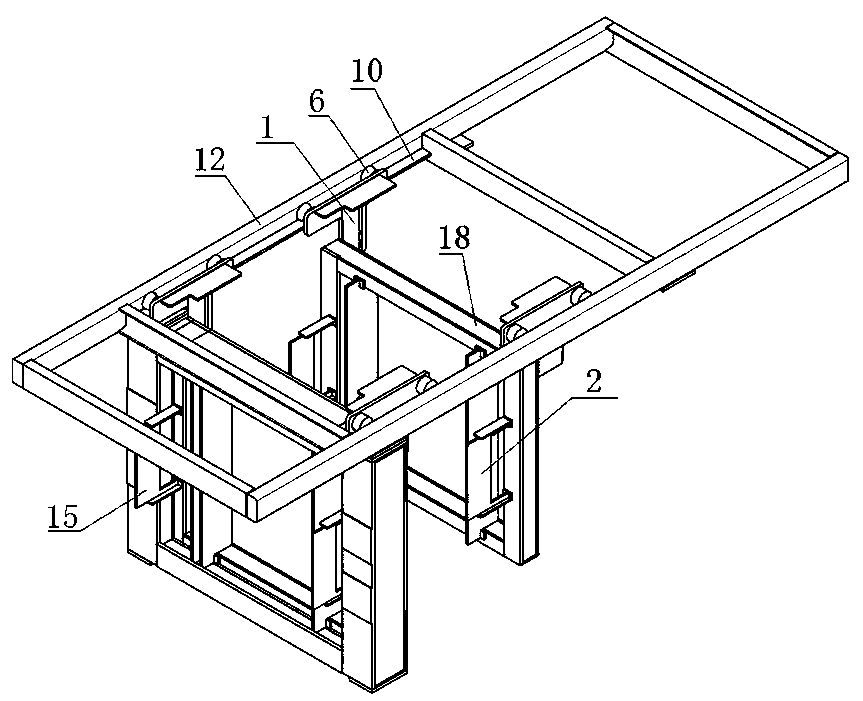

[0031] The quick mold change device 18 in this embodiment is used for quick mold change, saving mold change time and improving mold change efficiency. The quick mold change device 18 includes a mold change frame, a connector one 1, and a connector two 2, wherein the mold change frame is a hollow frame structure inside, and the connector one 1 and the connector two 2 are all located on the mold change frame 3 On the connecting piece 1, a sliding piece is provided.

[0032] Connecting piece 1 is used to assemble the mold changing frame on the foam molding machine frame 12, connecting piece 2 is used to connect the material gun to facilitate feeding, connecting piece 1 and connecting piece 2 are installed on the mold changing on the frame 3, and there are multiple ones installed, but it is necessary to ensure that the multiple connectors one 1 are located on the opposite side of the same direction of the mold change frame 3, which is convenient for hoisting, and the multiple conn...

Embodiment 2

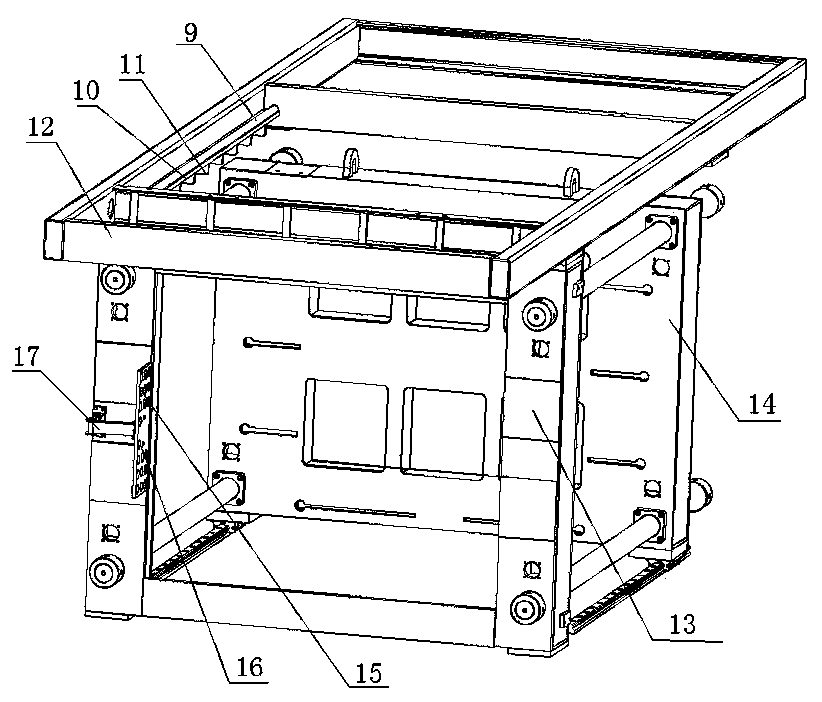

[0038] In this embodiment, the quick mold change frame provided by Embodiment 1 is adopted, and the structure of the quick mold change frame is not described in detail, and the structure adopted for the installation of the quick mold change frame and the frame 12 of the foam molding machine is further described. In the foam forming machine of the present embodiment, the frame 12 has a structure such as figure 2As shown, it includes a quick mold change device 18, a mold fixing frame 13, and a mold moving frame 14 positioned on the frame 12 of the foam molding machine, wherein the mold fixing frame 13 is fixed on the foam molding machine frame 12, the The mold moving frame 14 is movably connected on the foam molding machine frame 12 and moves forward and backward relative to the mold fixing frame 13. The quick mold changing device 18 is freely installed between the mold fixing frame 13 and the mold moving frame 14. The mold device 18 comprises a die changing frame, a connector ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com