Novel anti-end leakage filter element

A filter element and leakage filtration technology, applied in the field of filtration, can solve the problems of small contact area between water and filter element, short service life of filter element, weak filter element dirt holding capacity, etc., and achieve reasonable structure design, prolong service life and excellent filtering effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

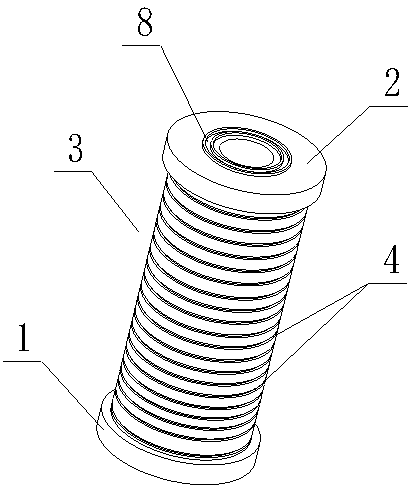

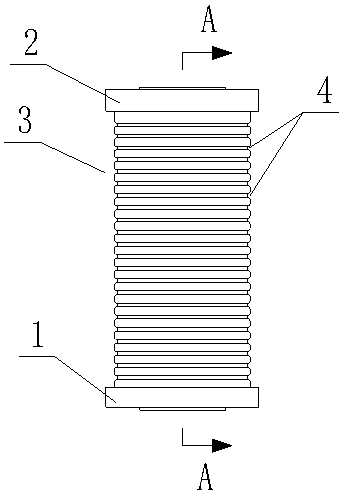

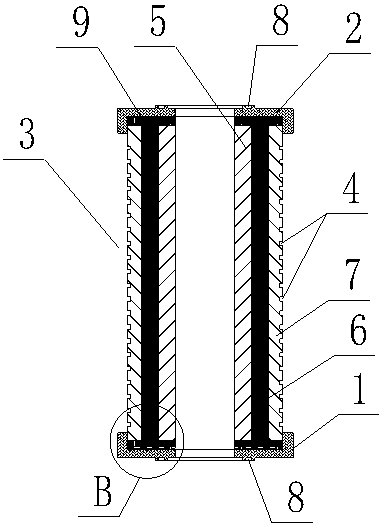

[0016] Specific embodiment one, please refer to Figure 1-4 , a novel anti-end leakage filter element, comprising a lower end cover 1, an upper end cover 2 and a filter element body 3, the upper and lower ends of the filter element body 3 are provided with a hot-melt layer 9, the thickness of the hot-melt layer 9 is 5 mm, The upper end cover 2 is fixed on the hot-melt layer 9 at the upper end of the filter body 3, the lower end cover 1 is fixed on the hot-melt layer 9 at the lower end of the filter body 3, and the filter body 3 is PP fiber layer from outside to inside. 7. Activated carbon layer 6 and PE layer 5, the outer surface of the filter element body 3 is provided with a plurality of grooves 2, the depth of the groove 2 is 4.4 mm, and the width of the groove 2 is 2.4 mm, so The lower end cover 1 and the upper end cover 3 are provided with a gasket groove 8, the lower end cover 1 and the upper end cover 2 are fixed on the two ends of the filter element body 3 by hot press...

specific Embodiment 2

[0017] Specific embodiment two, please refer to Figure 1-4 , a novel anti-end leakage filter element, comprising a lower end cover 1, an upper end cover 2 and a filter element body 3, the upper and lower ends of the filter element body 3 are provided with a hot-melt layer 9, the thickness of the hot-melt layer 9 is 5 mm, The upper end cover 2 is fixed on the hot-melt layer 9 at the upper end of the filter body 3, the lower end cover 1 is fixed on the hot-melt layer 9 at the lower end of the filter body 3, and the filter body 3 is PP fiber layer from outside to inside. 7. Activated carbon layer 6 and PE layer 5, the outer surface of the filter element body 3 is provided with a plurality of grooves 2, the depth of the groove 2 is 4.6 mm, and the width of the groove 2 is 2.6 mm, so The lower end cover 1 and the upper end cover 3 are provided with a gasket groove 8, the lower end cover 1 and the upper end cover 2 are fixed on the two ends of the filter element body 3 by hot press...

specific Embodiment 3

[0018] Specific embodiment three, please refer to Figure 1-4 , a novel anti-end leakage filter element, comprising a lower end cover 1, an upper end cover 2 and a filter element body 3, the upper and lower ends of the filter element body 3 are provided with a hot-melt layer 9, the thickness of the hot-melt layer 9 is 5 mm, The upper end cover 2 is fixed on the hot-melt layer 9 at the upper end of the filter body 3, the lower end cover 1 is fixed on the hot-melt layer 9 at the lower end of the filter body 3, and the filter body 3 is PP fiber layer from outside to inside. 7. Activated carbon layer 6 and PE layer 5, the outer surface of the filter element body 3 is provided with a plurality of grooves 2, the depth of the groove 2 is 4.8 mm, and the width of the groove 2 is 2.8 mm, so The lower end cover 1 and the upper end cover 3 are provided with a gasket groove 8, the lower end cover 1 and the upper end cover 2 are fixed on the two ends of the filter element body 3 by hot pre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com