Damping comb type expansion joint device

A technology of expansion joints and comb-tooth type, which is applied in the field of bridge expansion joints, can solve problems such as damage to comb-tooth expansion joints, vehicle jumping, and affecting the service life of bridges, so as to reduce the maximum load, reduce load, and prevent rainwater from intruding Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings, and the examples given are only for explaining the present invention, and are not intended to limit the scope of the present invention.

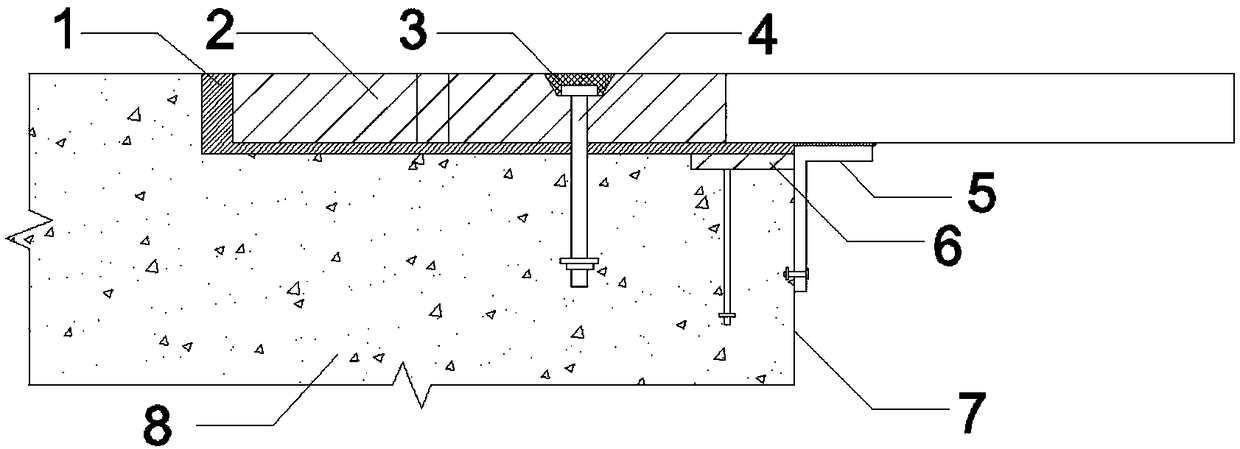

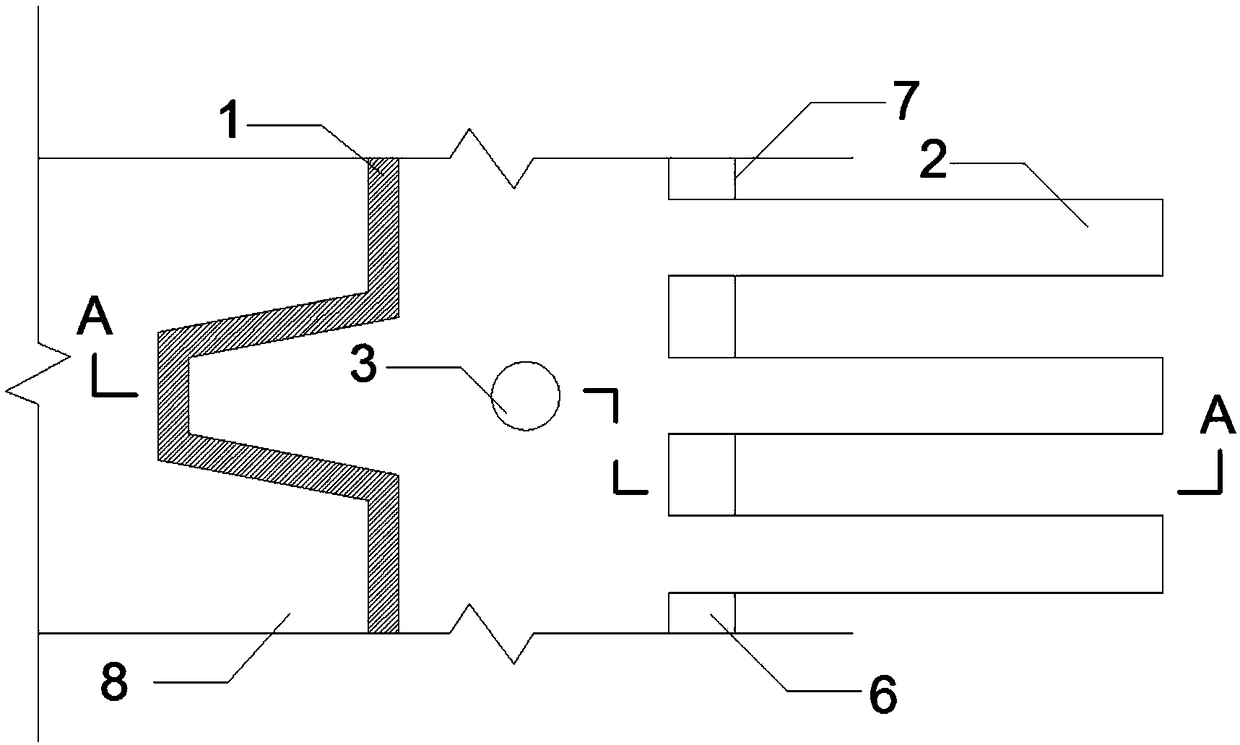

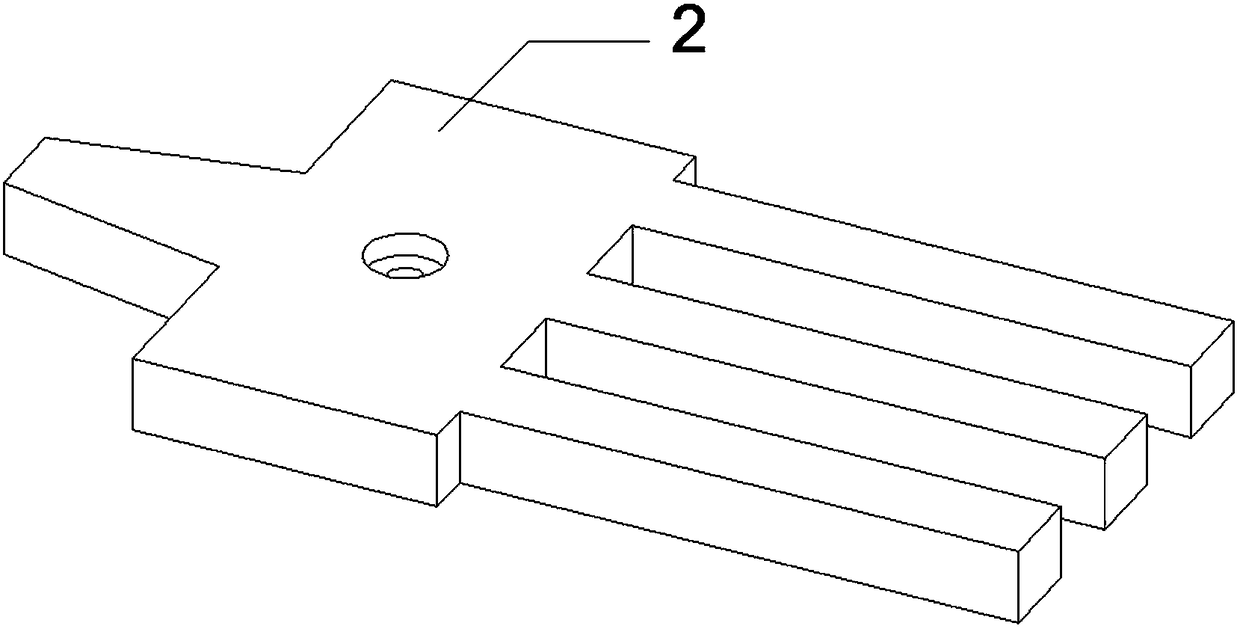

[0031] The present invention is a comb-type expansion joint device for vibration reduction, which includes a vibration-damping and waterproof weak cushion 1, a comb-tooth plate 2, anchor bolts 4, and a cement base 8; the vibration-damping and waterproof weak cushion 1 is arranged between the comb-tooth plate and Between the cement base 8.

[0032] Preferably, grooves are reserved in the cement base 8 at the rear of the comb plate 2 and the lower part, and the damping and waterproof weak cushion 1 is placed therein, and the upper surface of the comb plate 2 is basically the same as the highest surface of the cement base 8. on the same plane.

[0033] Place the vibration-damping waterproof cushion 1 in the gro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com