Luggage rack for long-distance coach luggage compartment

A technology of long-distance buses and luggage compartments, which is applied in the field of luggage racks, can solve the problems of inconvenient access to suitcases, increase the driver's workload, delay travel time, etc., and achieve the effects of power saving, light weight, and smooth sliding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to better understand the present invention, the implementation manner of the present invention will be explained in detail below in conjunction with the accompanying drawings.

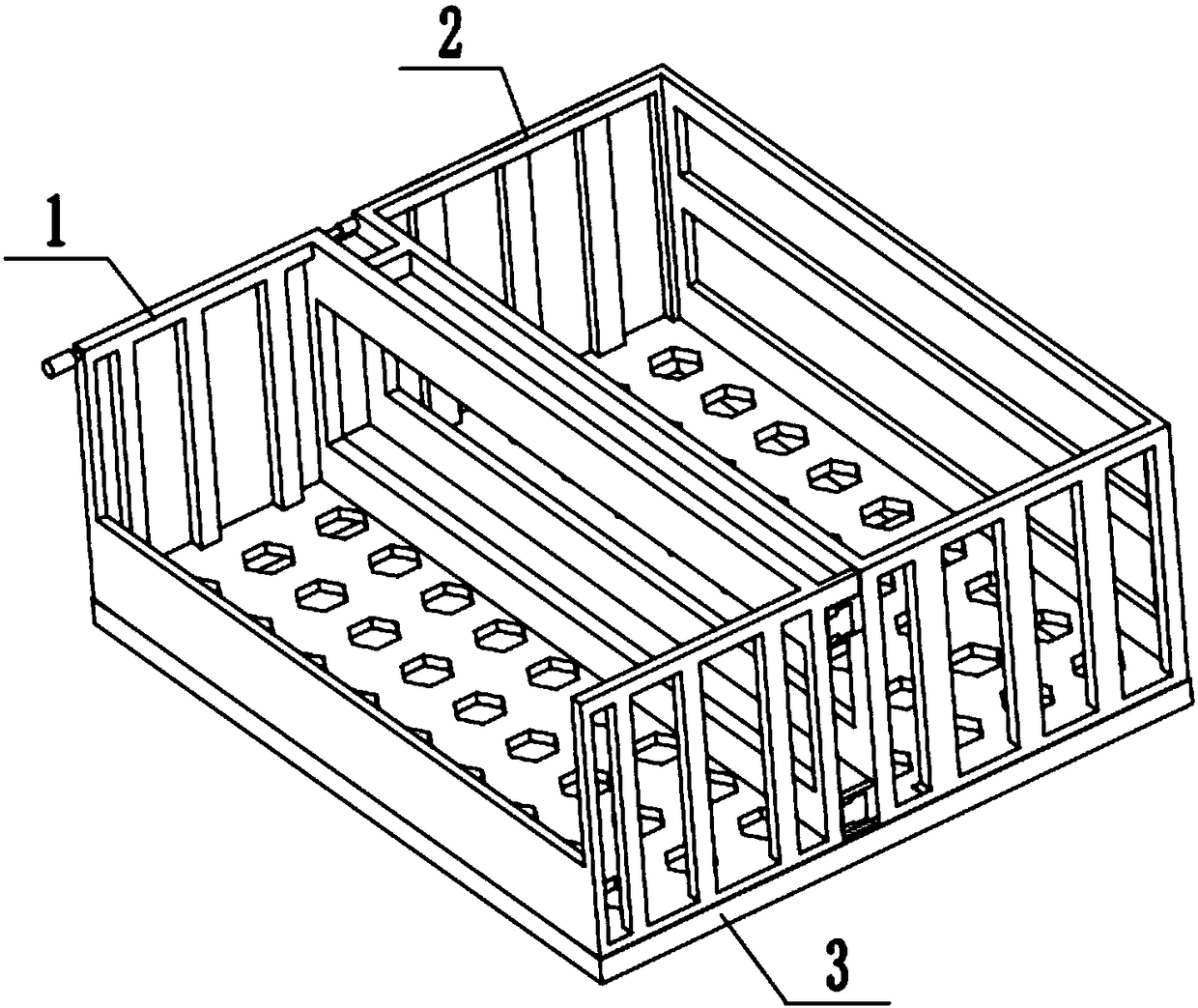

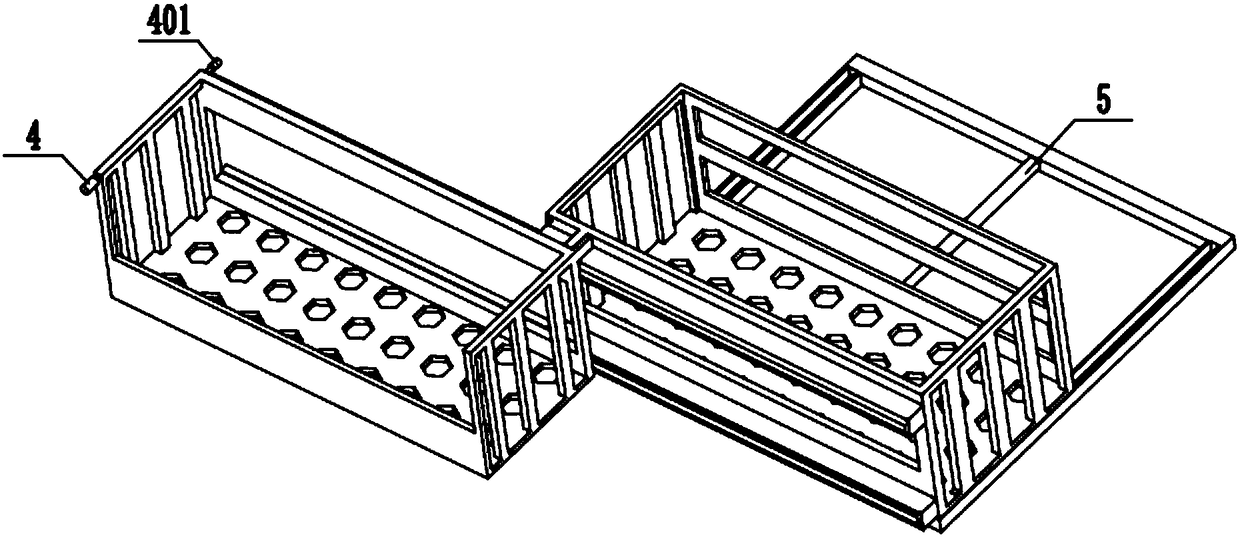

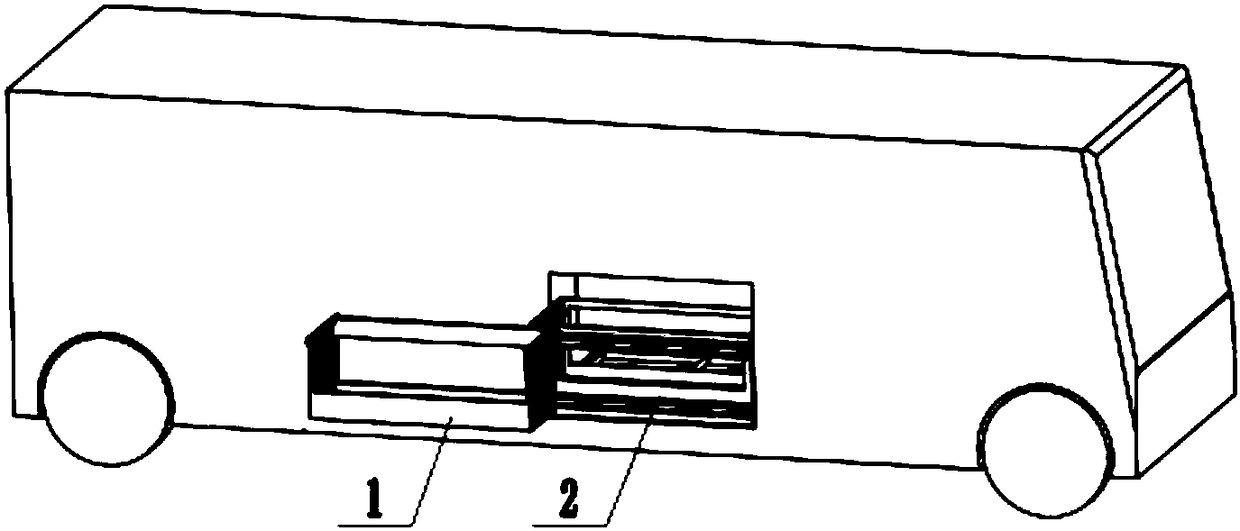

[0028] Such as Figure 1-10 As shown, a luggage rack for a long-distance bus luggage compartment includes an outer rack 1, an inner rack 2, a slide rail rack 3, a locking push rod 4, and a hydraulic cylinder 5, and the slide rail rack 3 is a rectangular frame structure, the slide rail frame 3 includes a rear support rod 301, a slide rail 302, and a front stop rod 303. Be provided with rail groove 304, the inner wall of rail groove 304 both sides is all provided with fixed groove 305, and described inner placement frame 2 and outer placement frame 1 are all arranged on the upper end of slide rail frame 3, and the lower end both sides of inner placement frame 2 Bottom slide bar 209 is provided, and described bottom slide bar 209 cooperates with rail groove 304, fixing groove 305 respecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com