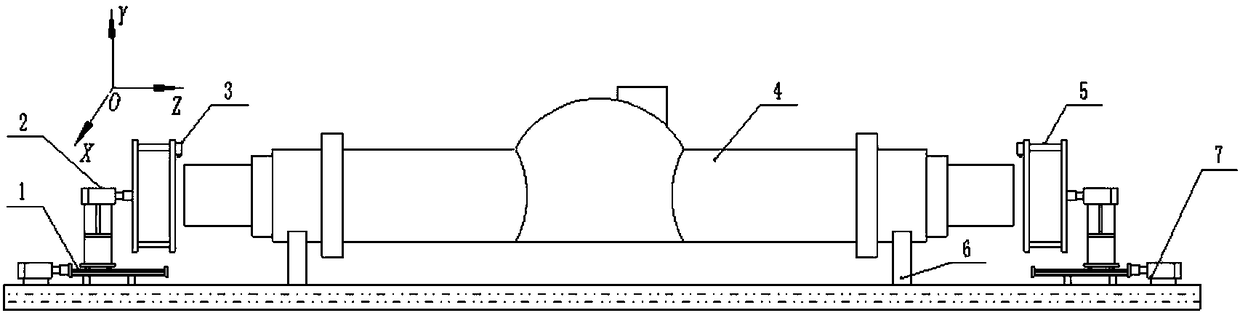

Workpiece axis positioning error compensation method for axle housing roundness and cylindricity detecting device

A technology of detection device and compensation method, which is applied to measurement devices, optical devices, instruments, etc., can solve the problems of not meeting detection conditions, not having an adjustable and movable bearing platform, and being expensive, so as to achieve the effect of increasing detection accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0068] A method for compensating the positioning error of a workpiece axis in an axle housing roundness and cylindricity detection device, comprising the steps of:

[0069] 1) Axle housing axis positioning eccentricity error compensation

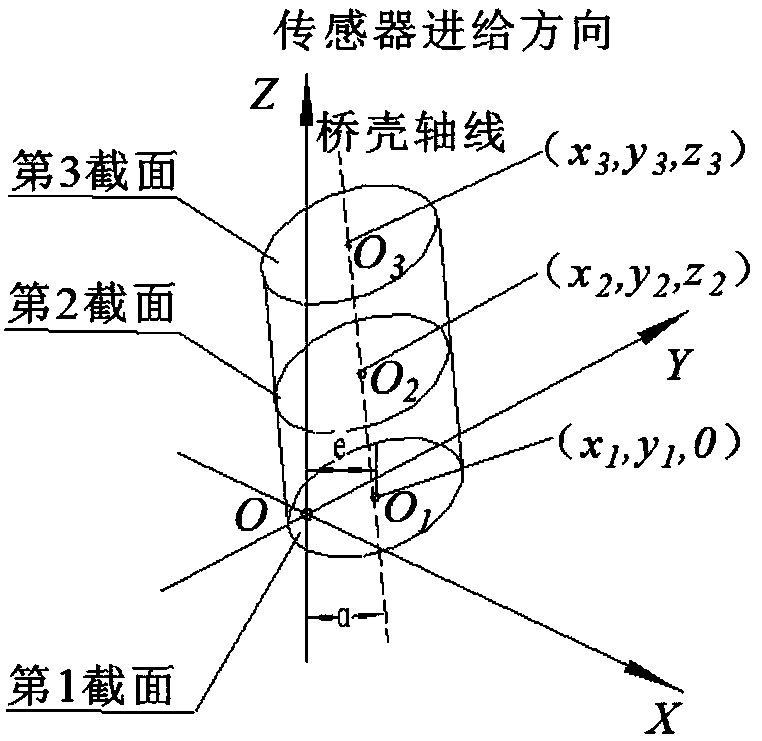

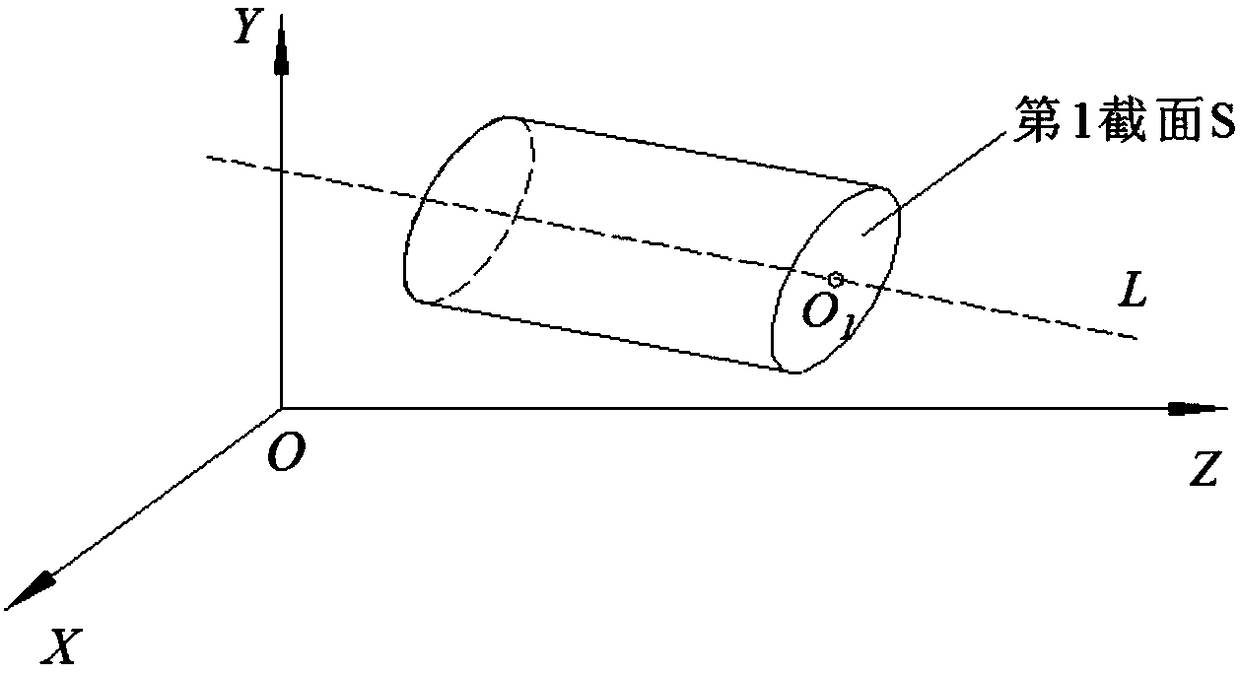

[0070] 1) Establish the positioning model of the axle housing;

[0071] Such as figure 2 As shown, the spatial reference coordinate system is established based on the laser displacement sensor, and the XOY coordinate plane is established on the rotation plane of the laser displacement sensor. The center of rotation is the origin O, and the ordinate of the point on the XOY coordinate plane is 0; The direction is taken as the positive direction of the Z axis for mathematical modeling; the first section, the second section, and the third section are respectively set on the established axle housing positioning model; among them, the center of the first section is O 1 The coordinates are (x 1 ,y 1 , 0), the center mark O of the second cross-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com