Circuit breaker automatic material separating table

A circuit breaker and automatic technology, applied in the direction of conveyor objects, transportation and packaging, etc., can solve the problem of difficult to achieve simple, neat and beautiful production scenes, difficult to achieve uninterrupted work mode, inconsistent supply speed and production speed, etc. problems, to achieve the effect of meeting quality requirements and stability, improving procedural and normative, and reducing labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

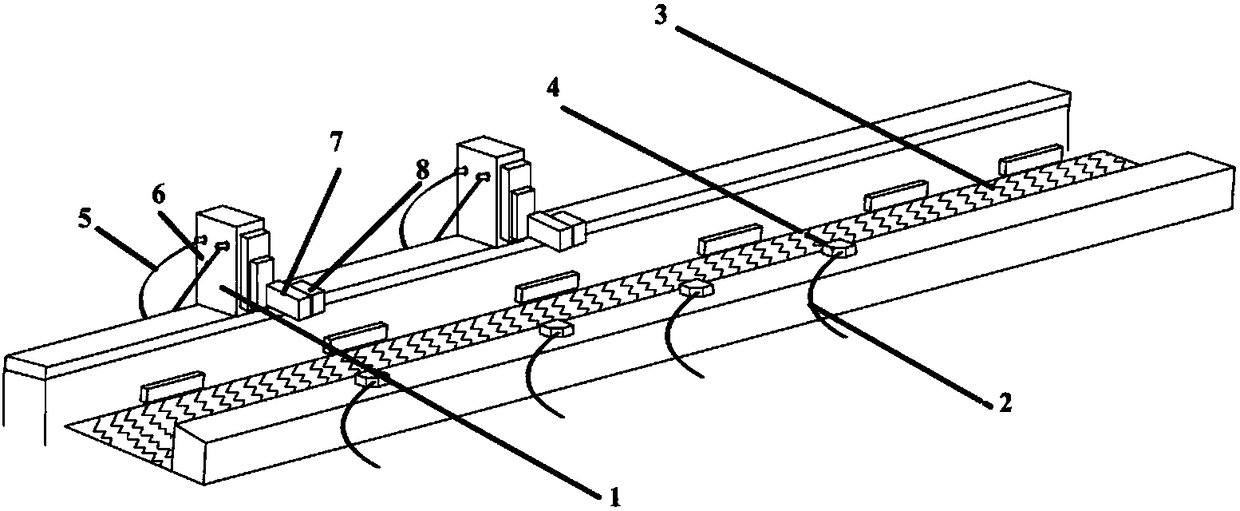

[0016] Such as figure 1 As shown, an automatic material partition table for a circuit breaker of the present invention includes a cylinder 1, a signal line 2, a conveyor belt 3, an infrared sensor 4, a control line 5, a power line 6, an elastic arm 7 and a buffer plate 8. The cylinder 1 is provided with a control line 5 and a power line 6, the infrared sensor 4 is provided with a signal line 2, the elastic arm 7 and the buffer sheet 8 are tightly connected together in the form of riveting, and the conveyor belt 3 is located in the middle of cylinder 1, control line 5, power line 6, elastic arm 7, buffer sheet 8, infrared sensor 4, and signal line 2, the cylinder 1, control line 5, power line 6, elastic arm 7, buffer sheet 8 is located on the le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com