New-energy vehicle charging pile

A technology for new energy vehicles and charging piles, which is applied to electric vehicle charging technology, charging stations, electric vehicles, etc., can solve the problems of difficulty in removing the charging cable, occupying internal space, uneven coiling, etc., and achieves convenient operation. , Improve the replacement speed, improve the effect of wire coiling speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

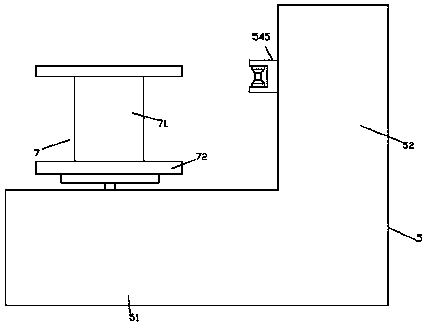

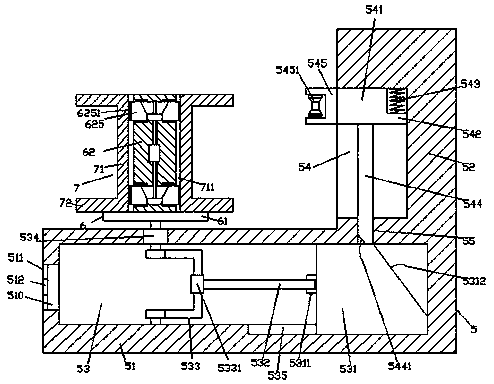

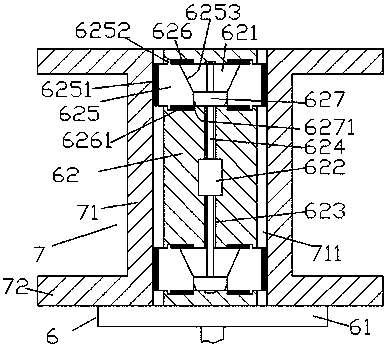

[0022] Such as Figure 1-Figure 6 As shown, a new energy vehicle charging pile of the present invention includes a wire coiled base 5 composed of a first base 51 and a second base 52 arranged inside the charging pile. The first base 51 is provided with left and right extensions. The cavity 53, the right side of the cavity 53 is provided with a first chute 535, the first chute 535 is provided with a slider 531 that is smoothly fitted and connected, and the slider 531 in the cavity 53 The left side is provided with a rotating base 5311, and the rotating base 5311 is rotatably connected with a push slide bar 532 extended to the left. The tube 5331 is provided with a rotating connecting zigzag piece 533, the front side of the rotating connecting zigzag piece 533 is connected in rotation with the front inner wall of the cavity 53, and the rear side of the rotating connecting zigzag piece 533 is connected with the electric wire coiling power device 534 The electric wire coiling pow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com