Automatic assembling device for DC contactor

A technology of automatic assembly device and DC contactor, which is applied in assembly machines, metal processing, metal processing equipment, etc., can solve the problems of cost pressure and slow production speed of manufacturers, and achieve lower labor costs, reasonable structure and good application prospects. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

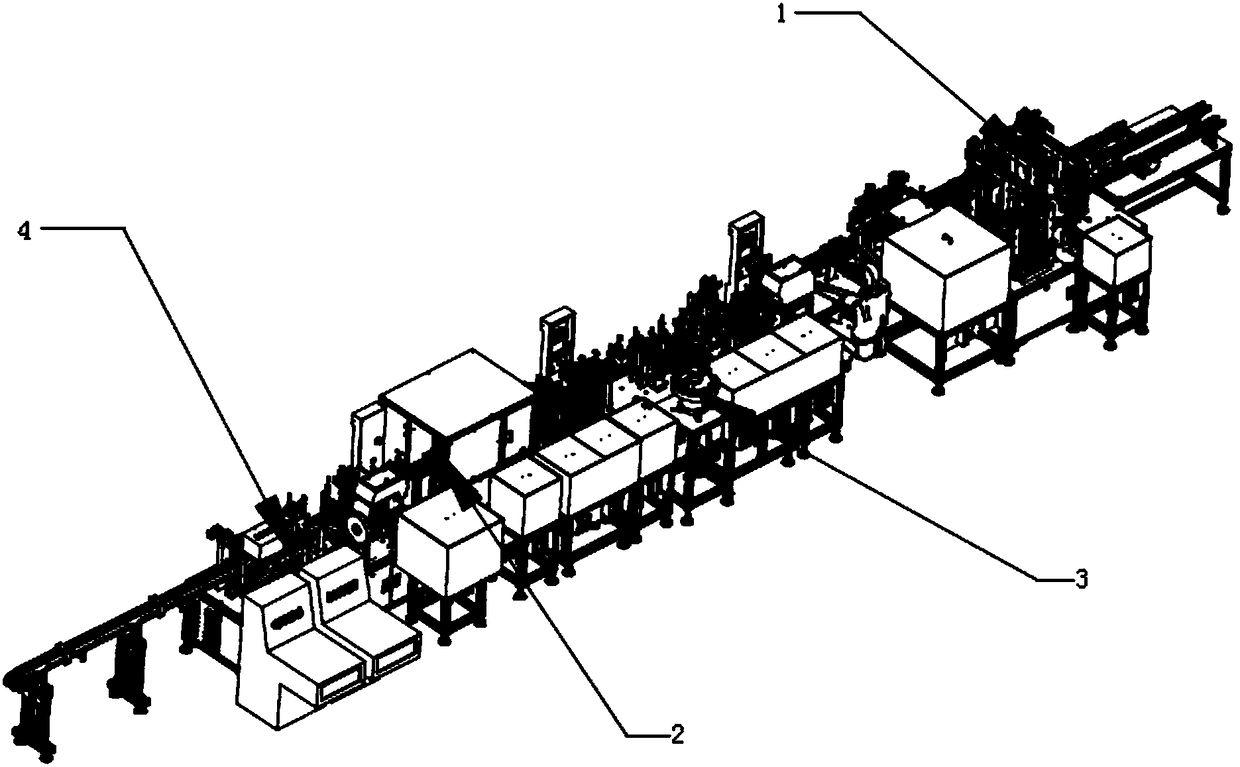

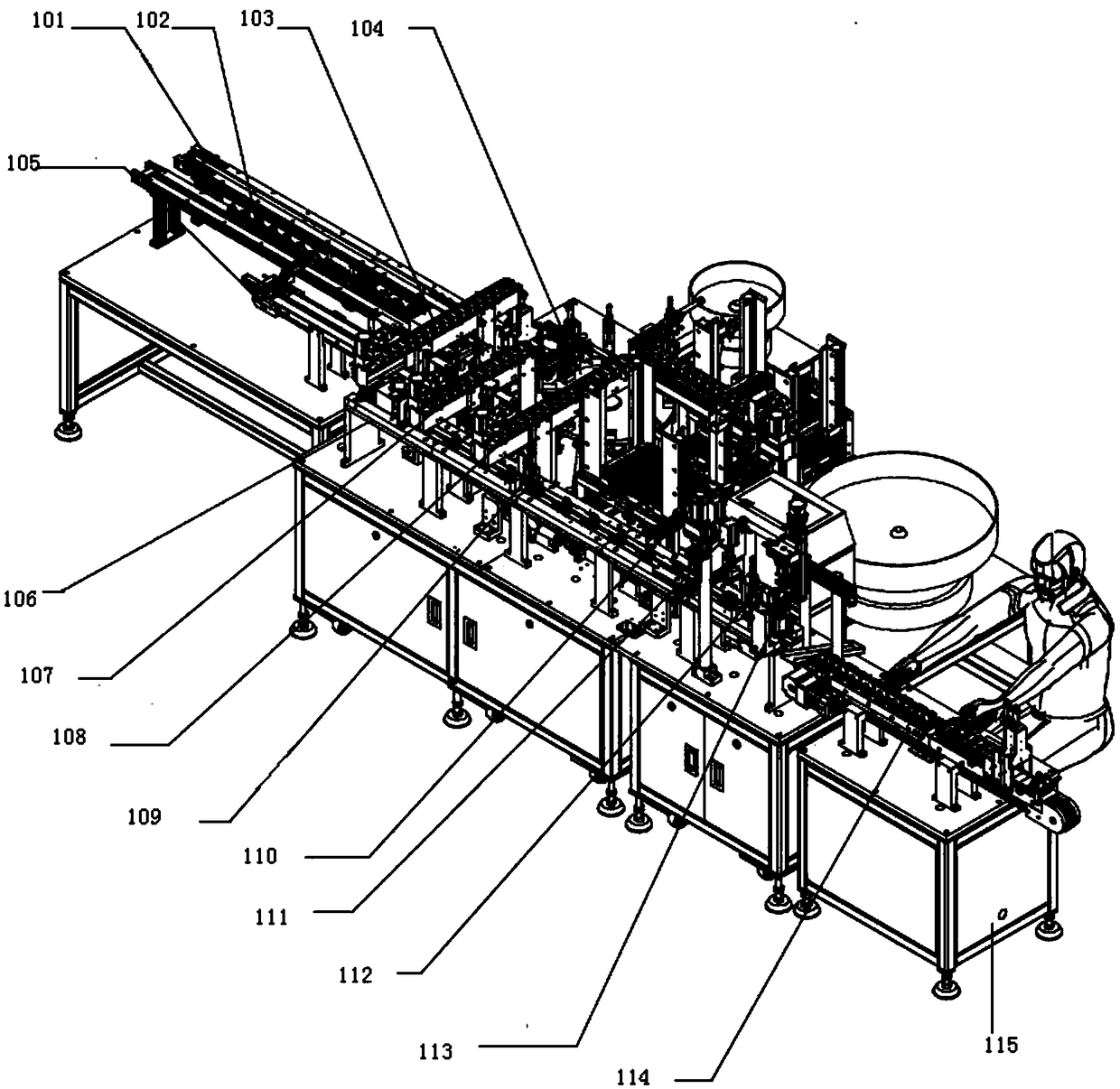

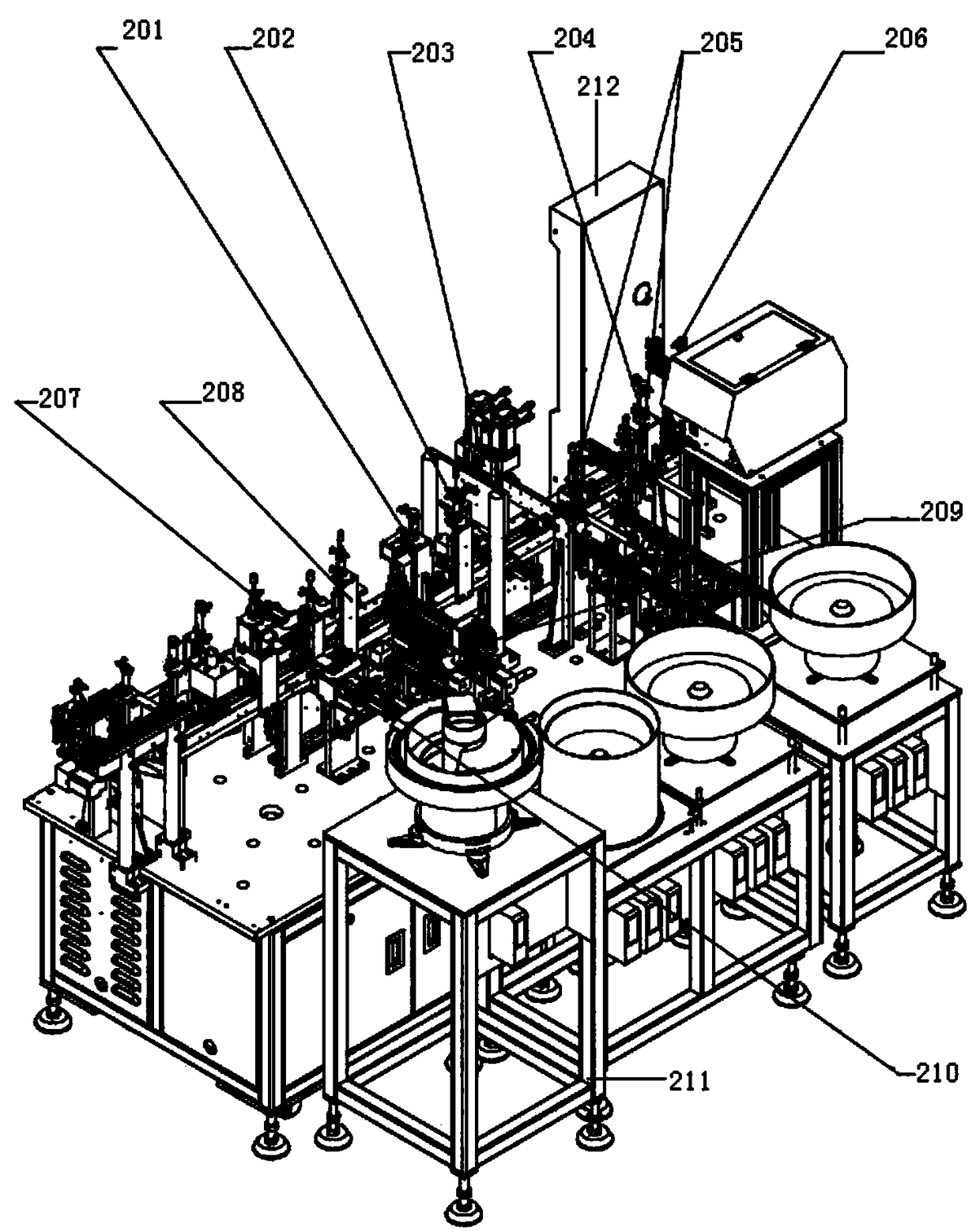

[0021] figure 1 , 2 , 3, 4, 5, and 7, the DC contactor automatic assembly device, including supporting facilities to ensure the normal operation of the overall equipment, has four sub-equipment 1, 2, 3, 4, the first sub-equipment includes the bending frame conveying Belt 101, connecting frame conveyor belt 102, connecting frame feeding mechanism 103, straight skeleton assembly mechanism 104, excitation rod conveyor belt 105, shift fork mechanism 106, excitation rod feeding mechanism 107, straight skeleton combined feeding mechanism 108, straight skeleton Combined detection mechanism 109, base plate feeding mechanism 110, locking screw mechanism 111, screw detection mechanism 112, sorting and unloading mechanism 113, excessive conveyor belt 114, all components of the first sub-equipment are installed on the first frame assembly 115, and the second The two-point equipment includes a turning mechanism 201, a screw detection mechanism 202, a locking screw mechanism 203, a connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com