Embedding component in component carrier by component fixation structure

A fixed structure and component bearing technology, applied in printed circuit components, semiconductor/solid-state device components, electrical components, etc., can solve problems such as difficulties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

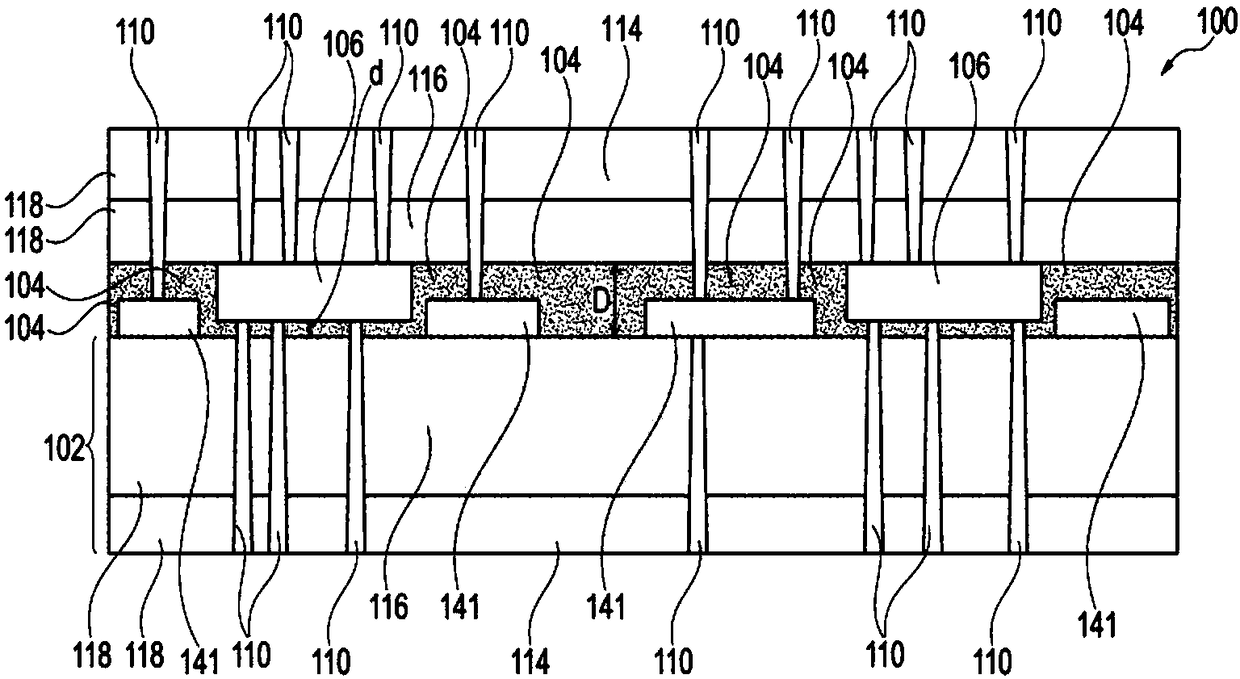

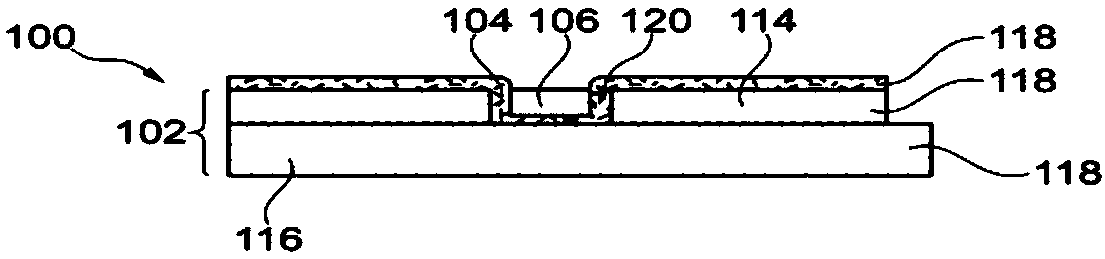

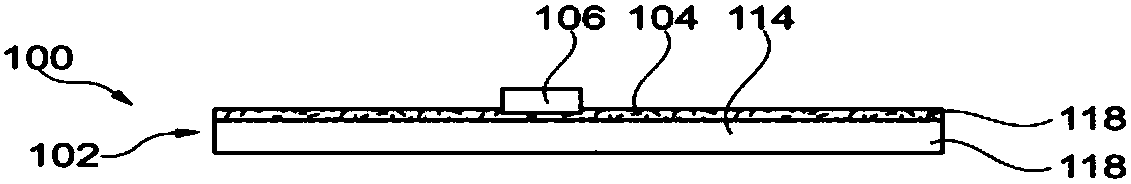

[0069] Before the exemplary embodiments will be described in further detail with reference to the accompanying drawings, some basic considerations on which the exemplary embodiments of the present invention are developed will be outlined.

[0070] According to an exemplary embodiment of the present invention, a method of embedding a component exhibiting warpage is provided. However, this method can also be performed on components that do not exhibit warpage.

[0071]Components exhibiting warpage are a significant problem when they are to be embedded in a component carrier such as a printed circuit board (PCB). In particular, this can cause problems when picking and placing parts with warpage. Traditionally, there has been no reasonable opportunity to integrate components with warpage into PCBs. The reason for this is that embedding a component with warpage in a component carrier such as a PCB generally translates as a whole into a warpage of the component carrier. This may ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com