A hydraulic folding and pulling type internal mold device

A pull-type, internal mold technology, which is applied to the erection/assembly of bridges, formwork/formwork/work frames, and on-site preparation of building components, which can solve the problems that the hydraulic folding pull-type internal mold device cannot be changed in size, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

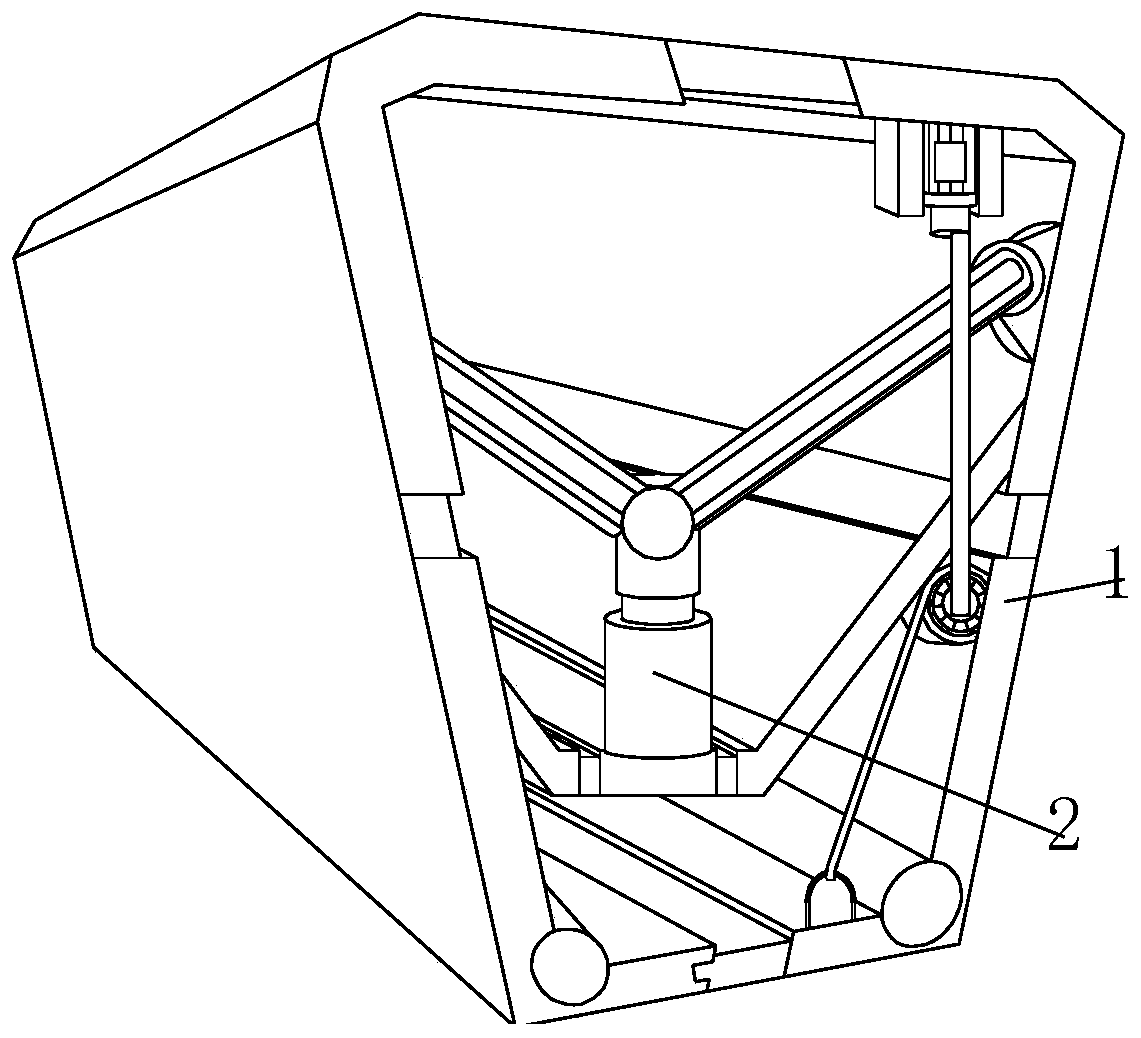

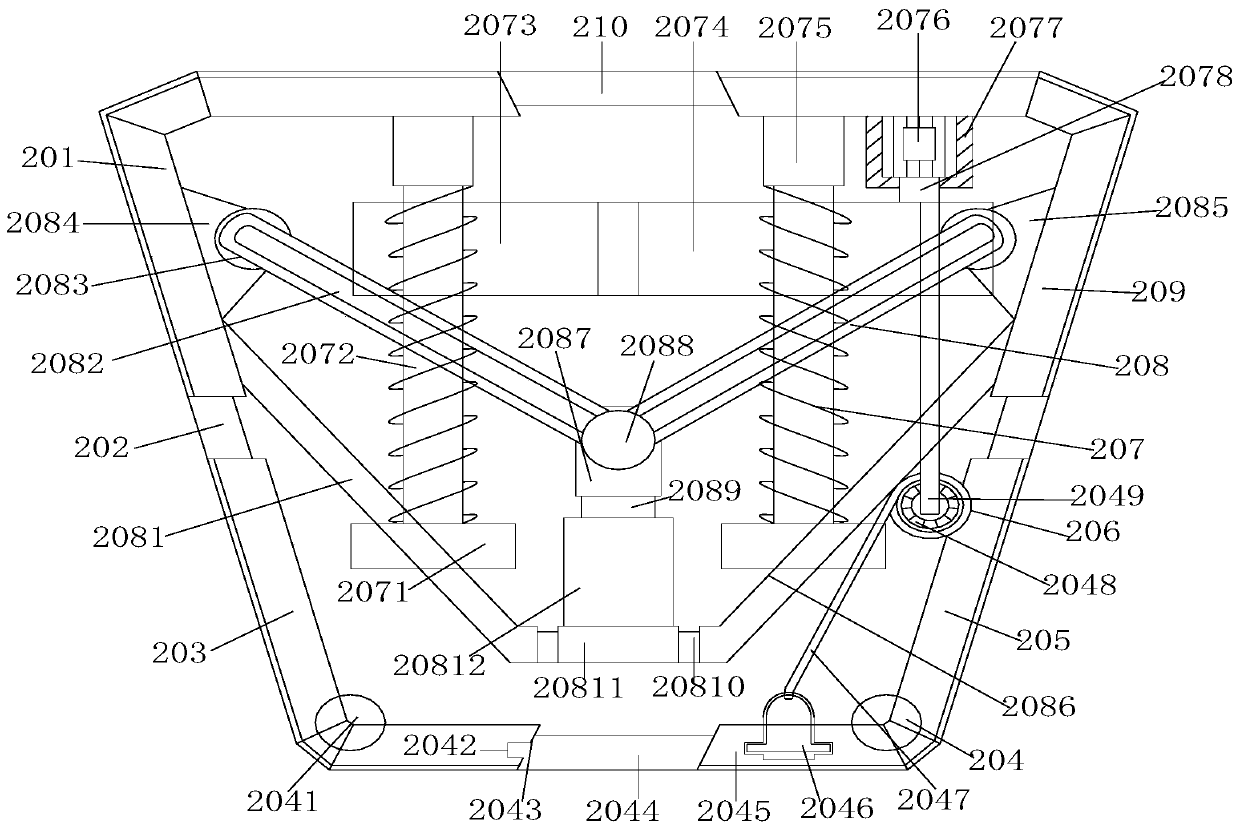

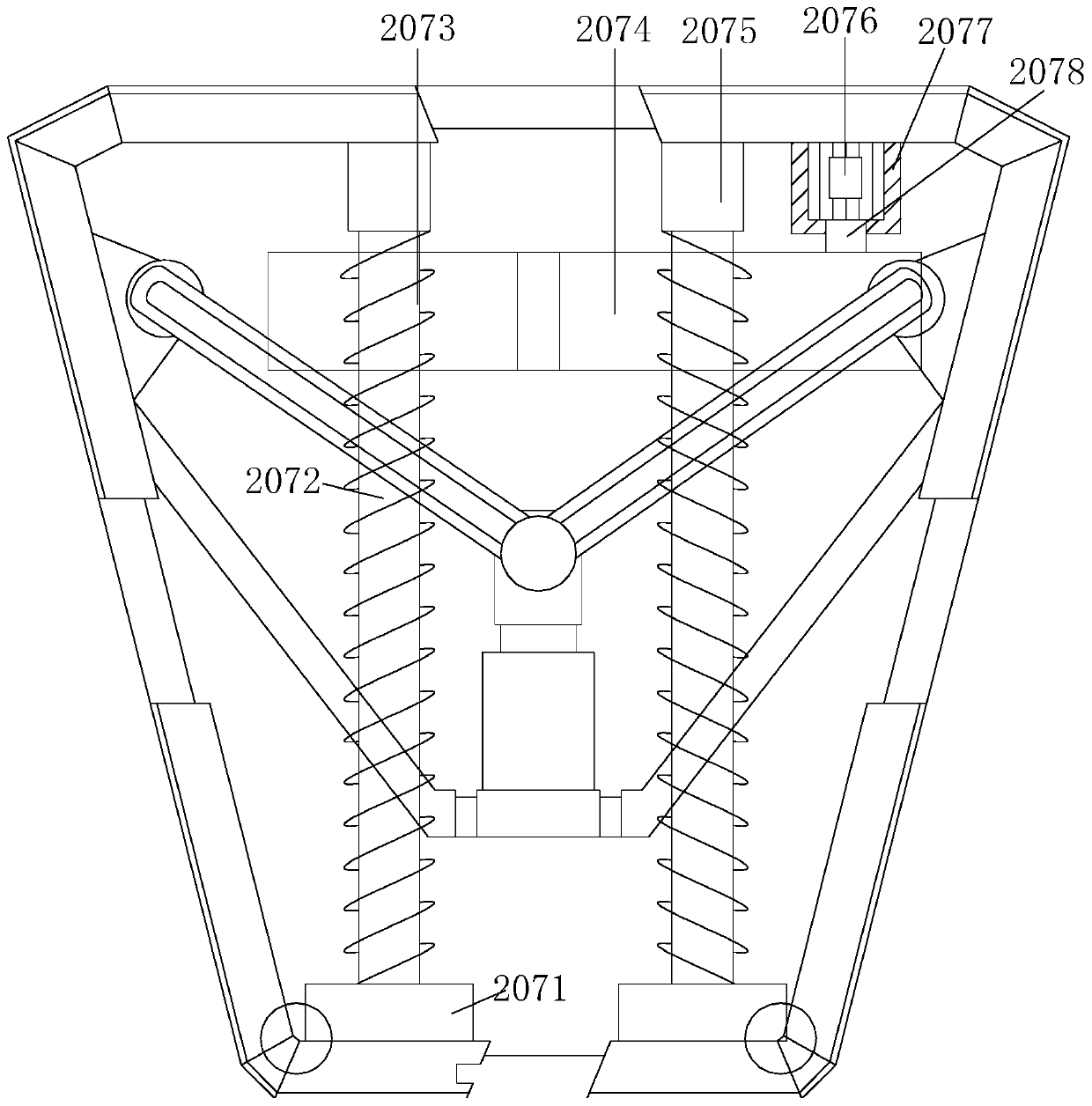

[0026] see Figure 1-Figure 6 , the present invention provides a technical solution of a hydraulic folding and pulling type inner mold device: its structure includes an outer shell 1 and an inner mold device 2, the inner mold device 2 is installed in the inner cavity of the outer shell 1, and the inner mold device 2 Mechanically connected with the inner wall of the shell 1, the inner mold device 2 is composed of No. 1 L-shaped inner formwork block 201, No. 1 telescopic plate 202, No. 2 L-shaped inner formwork block 203, folding device 204, and No. 3 L-shaped inner formwork block 205, fixed plate 206, height adjustment device 207, width adjustment device 208, No. 4 L-shaped inner formwork block 209, No. 2 telescopic plate 210, the No. 1 L-shaped in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com