Anti-bird-strike leading edge of airplane and support body therefor

A support body and support matrix technology, applied in the direction of bird impact prevention equipment, aircraft parts, wings, etc., can solve the problem of reducing the weight of the aircraft's leading edge structure, achieve the effect of small weight cost, easy implementation, and meet the strength requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, so as to more clearly connect the inventive principle and beneficial technical effects of the present invention.

[0052] Explanation of terms used in this article:

[0053] The extension direction of the anti-bird strike leading edge of the aircraft along the wingspan is called the longitudinal direction;

[0054] The direction perpendicular to the direction of extension of the leading edge is called transverse;

[0055] Along the transverse direction, the side adjacent to the front side of the leading edge is called the front;

[0056] In the transverse direction, the side adjacent to the rear of the leading edge is called the rear.

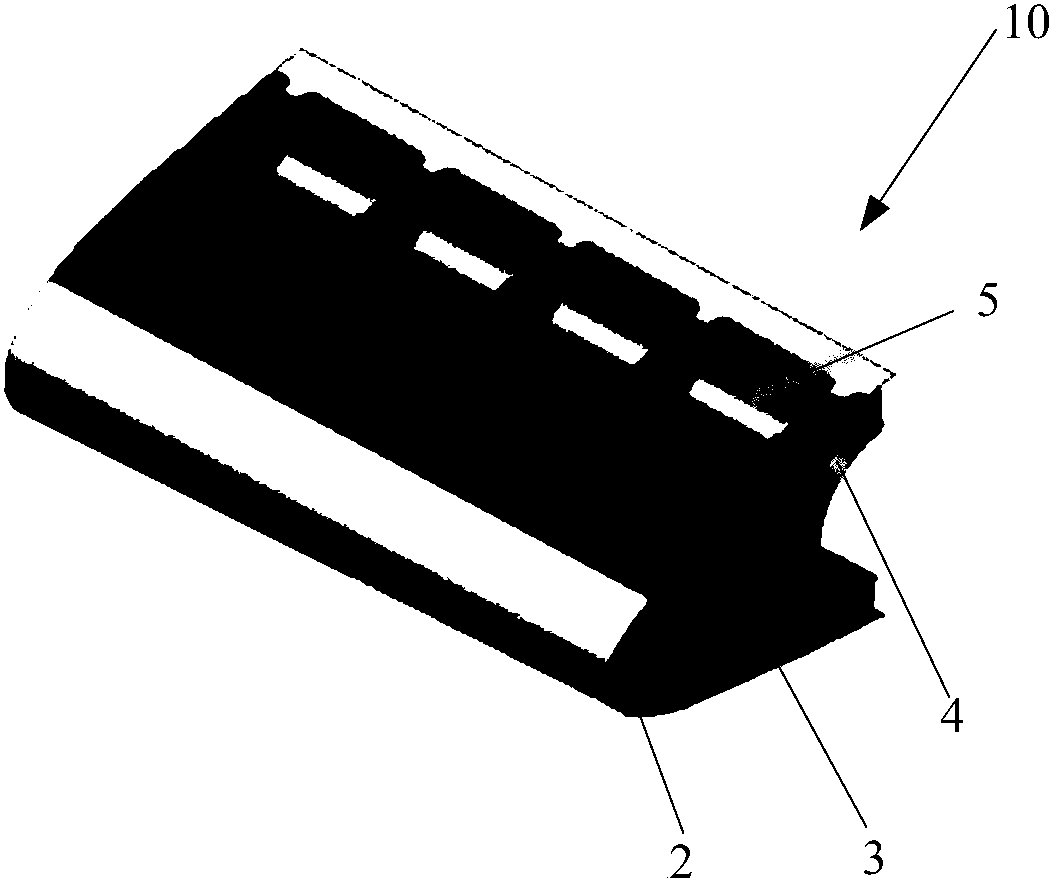

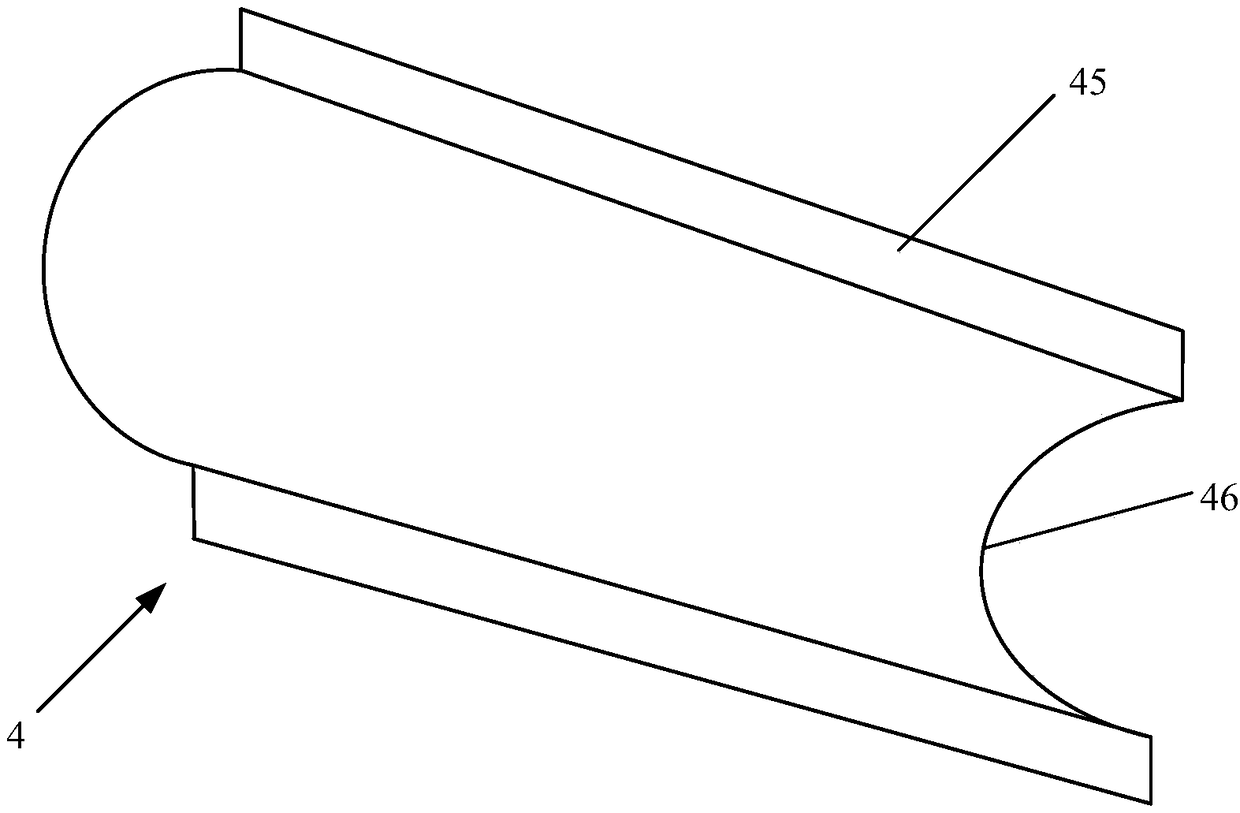

[0057] Such as figure 1 and 2 As shown, it shows a preferred embodiment according to the present invention. figure 1A perspective view of an anti-bird strike front edge 10 of an aircraft is shown, and the front edge 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com