Novel acoustic composite board production line and production method thereof

A production method and production line technology, applied in the field of new acoustic composite panel production line, can solve the problems of high production cost, low production efficiency and low degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

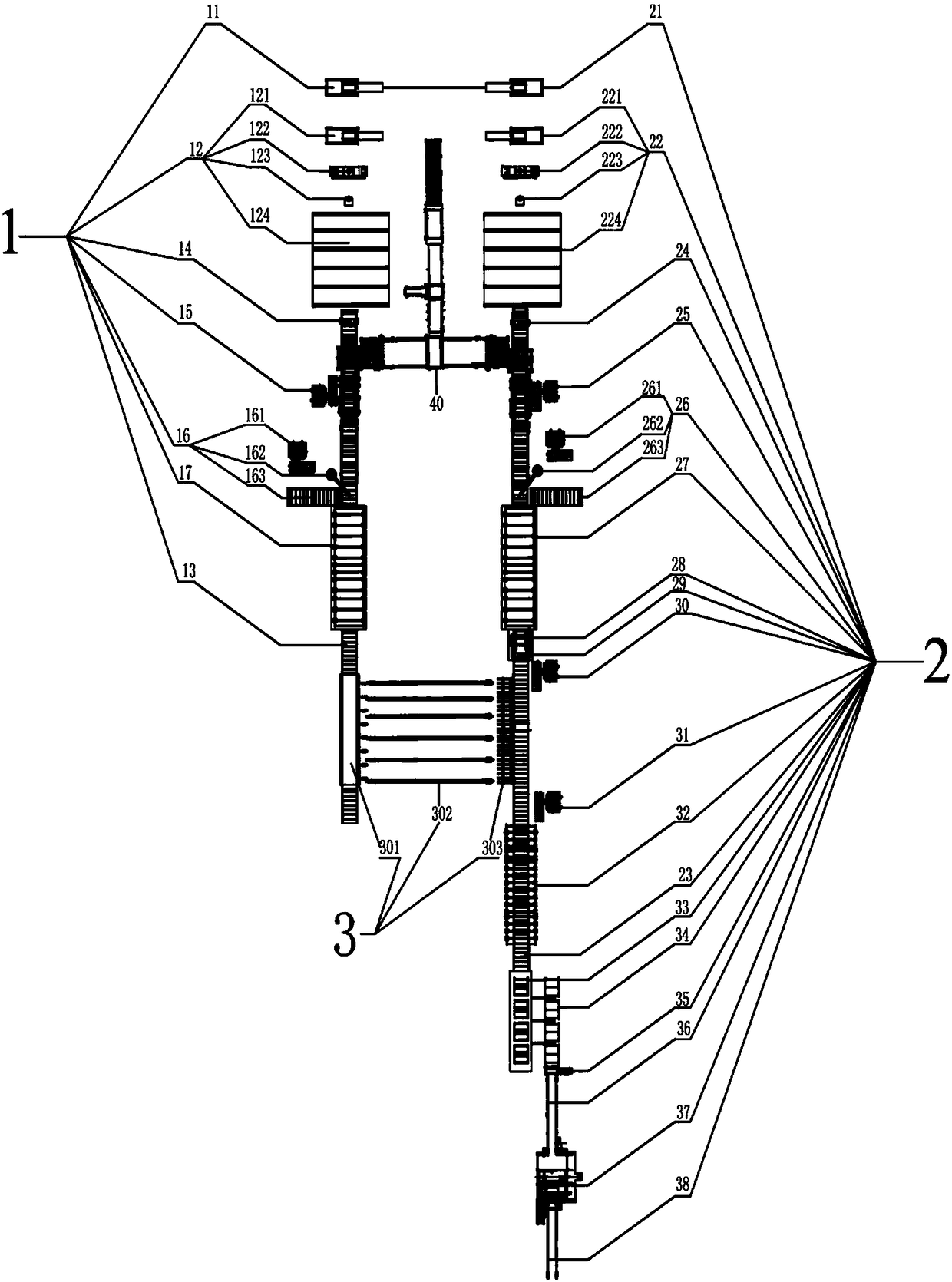

[0073] refer to figure 1 , the new acoustic composite panel production line includes a first production line 1, a second production line 2 and a connection section 3, the first production line 1 and the second production line 2 are arranged in parallel, and the connection section 3 is arranged transversely on the first production line 1 Between the second production line 2; the first production line 1 includes a first coil uncoiler 11, a first steel plate processing system 12, and a first longitudinal conveying roller table 13 arranged in sequence, along which the first longitudinal conveying roller Road 13 is provided with a first coil shearing machine 14, a first single-control gluing machine 15, a first cement board processing system 16, a first rubber roller press 17 and a translation device 301 in sequence. The shearing machine 14, the first rubber roller bearing machine 17 and the translation device 301 are all arranged on the first longitudinal conveying roller table 13...

Embodiment 2

[0101] The new acoustic composite panel production line refers to Example 1.

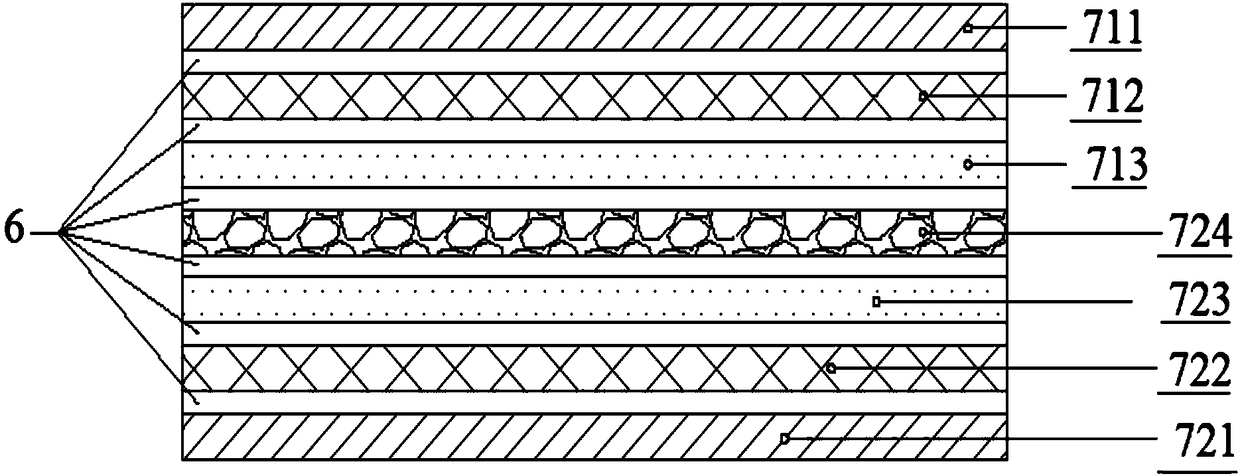

[0102] refer to Figure 4 The new acoustic composite panel involved in Example 2 includes a first steel plate 711 with holes on the surface, a glass fiber cloth layer 812, a first rock wool layer 712, a first cement board 713, and a damping material layer 724 arranged in sequence from top to bottom. , the second cement board 723, the second rock wool layer 722 and the second steel plate 721, between the first steel plate 711 with holes and the glass fiber cloth layer 812, the glass fiber cloth layer 812 and the first rock wool layer 712, between the first rock wool layer 712 and the first cement board 713, between the first cement board 713 and the damping material layer 724, between the damping material layer 724 and the second cement board 723 , between the second cement board 723 and the second rock wool layer 722, between the second rock wool layer 722 and the second steel plate 721, a glue coa...

Embodiment 3

[0121] The new acoustic composite panel production line refers to Example 1.

[0122] refer to Figure 5 The new acoustic composite panel involved in Example 3 includes a first steel plate 711 with holes on the surface, a glass fiber cloth layer 812, a first rock wool layer 712, a first non-woven fabric 813, and a polyurethane layer 93 arranged in sequence from top to bottom. , the second non-woven fabric 823, the second rock wool layer 722 and the second steel plate 721, between the first steel plate 711 with holes and the glass fiber cloth layer 812, the glass fiber cloth layer 812 and the first rock wool Between layers 712, between the first rock wool layer 712 and the first non-woven fabric 813, between the second non-woven fabric 823 and the second rock wool layer 722, between the second rock wool layer 722 and the second The steel plates 721 are all provided with a glue layer, the first steel plate 711 with holes, the glass fiber cloth layer 812, the first rock wool lay...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com