Practical welding device

A welding device and practical technology, applied in auxiliary devices, welding equipment, auxiliary welding equipment and other directions, can solve the problems of hidden safety hazards, simple fixing methods, low stability, etc., and achieve improved insertion stability, convenient operation, and structure. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

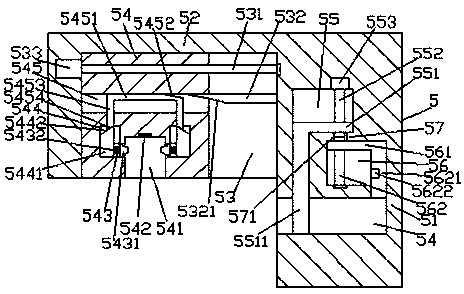

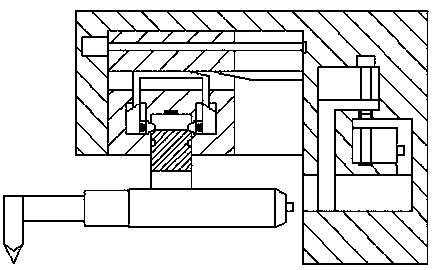

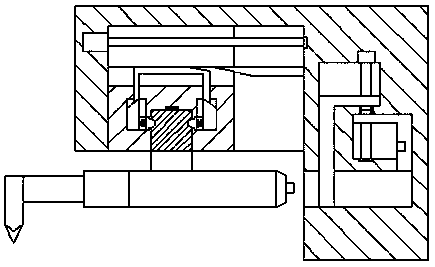

[0026] Such as Figure 1-Figure 8 As shown, a practical welding device of the present invention includes a fixed base 5 and an electric welding torch 6. The fixed base 5 includes a power feeding base 51 and an operation part 52 fixedly arranged on the upper left side of the power feeding base 51. An insertion slot 54 is provided in the end face of the lower left side of the power supply seat 51, and a first sliding cavity 56 is provided in the power supply seat 51 above the right side of the insertion slot 54. The first sliding cavity 56, a second sliding chamber 55 is provided in the power feeding seat 51 on the upper left side, and a baffle plate is provided between the inner top surface on the left side of the first sliding chamber 56 and the inner bottom surface on the right side of the second sliding chamber 55. 57, the first sliding cavity 56 is provided with a first screw rod 562 extending upward, and the second sliding cavity 55 is provided with a second screw rod 552 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com