Device of laser cutting machine for replacing same gas source quickly

A technology of laser cutting machine and air source device, which is applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of increasing time cost and reducing work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to clearly illustrate the technical features of this solution, the present invention will be described in detail below through specific implementation modes and in conjunction with the accompanying drawings.

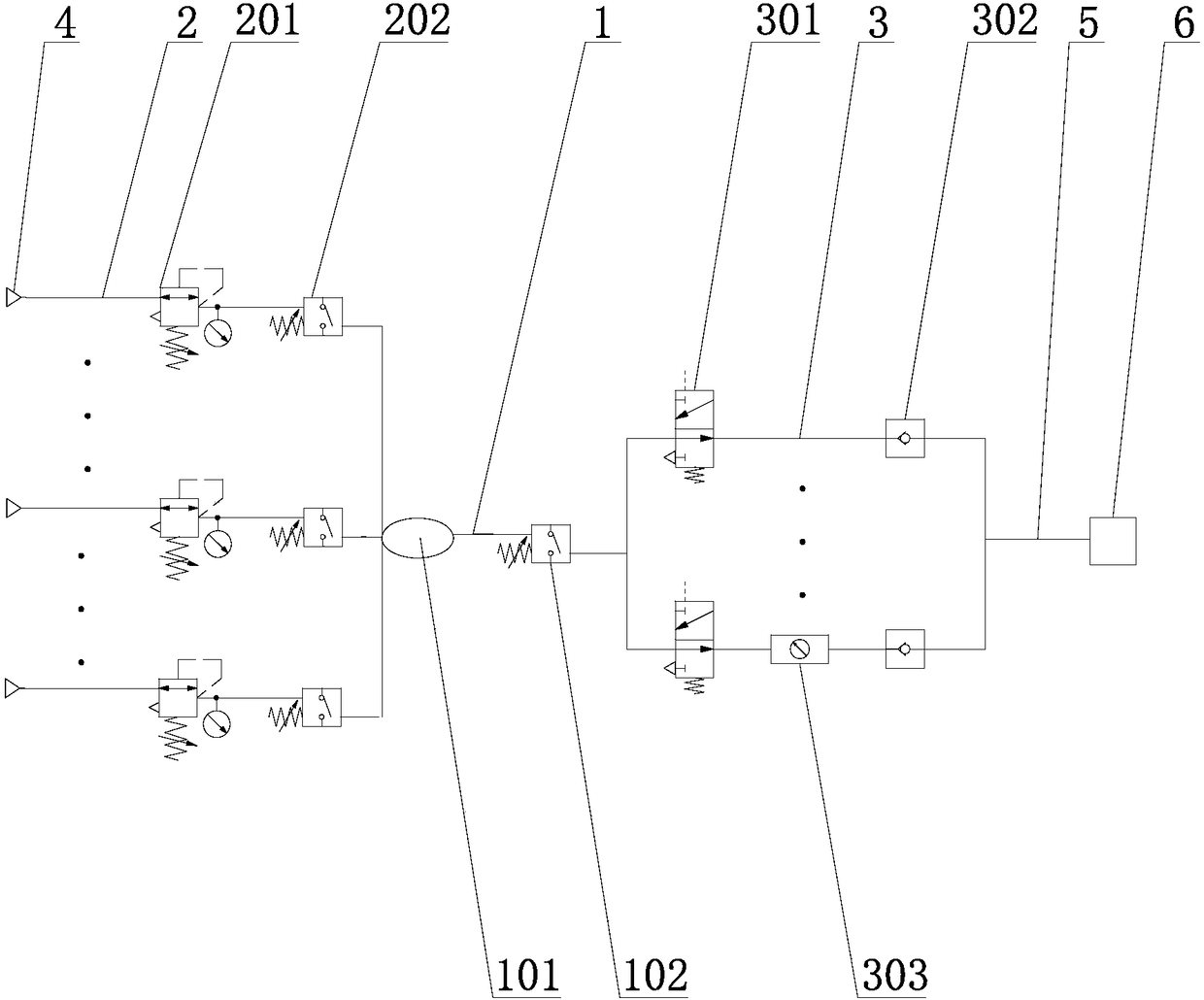

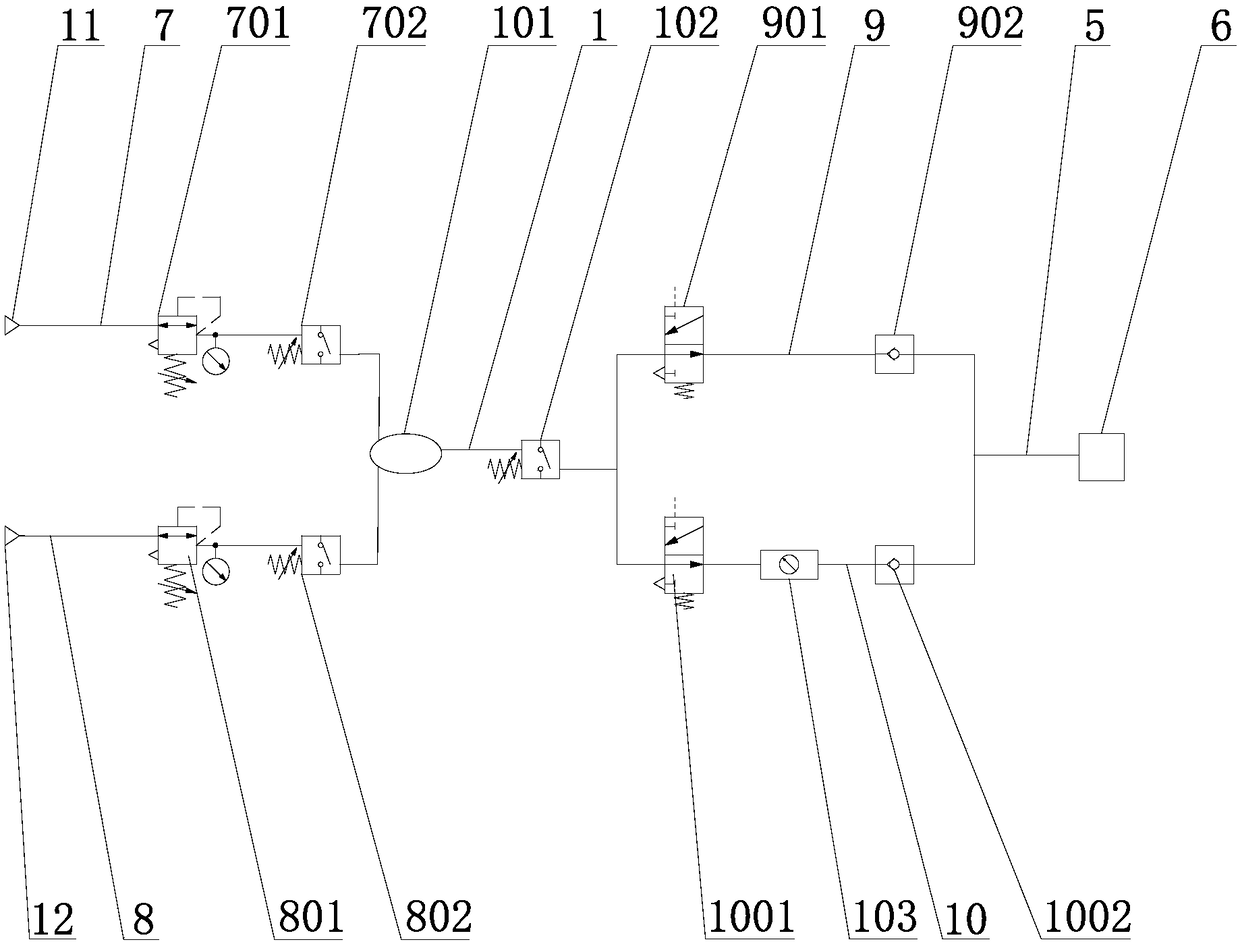

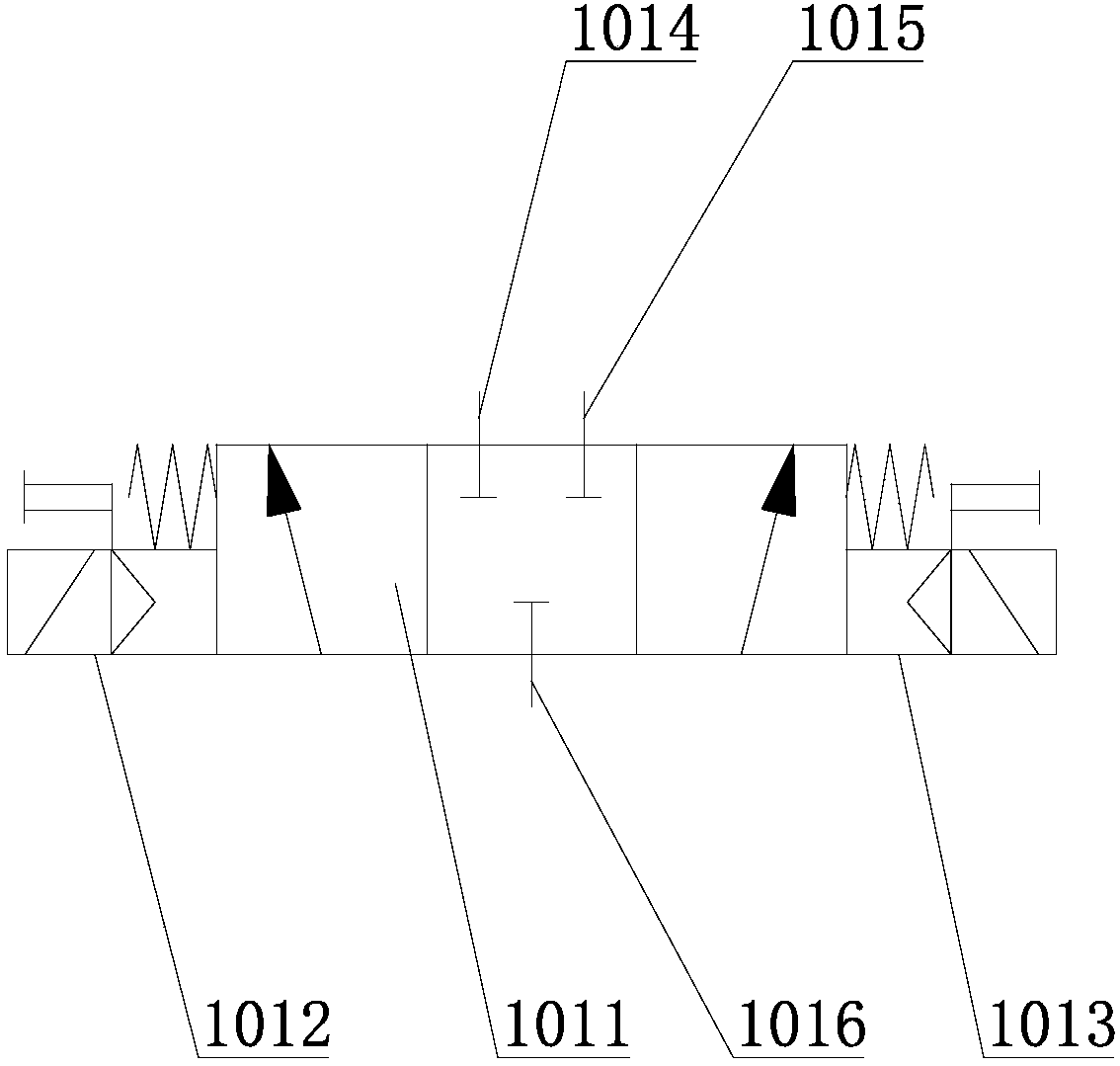

[0017] Such as figure 1 As shown, the laser cutting machine quickly replaces the same type of gas source device, including the main air inlet 1, the input ports of the main air inlet 1 are respectively connected to at least two inlet branch air circuits 2, and the output ports are respectively connected to at least two outlet branches Gas circuit 3, the input port of each inlet branch gas circuit 2 is connected to a gas source 4, all gas sources 4 are the same type of gas source, all output ports of the branch gas circuit 3 are connected to the input port of the main gas circuit 5, and the outlet The output port of the main air circuit 5 is connected to the laser head 6. The main air circuit 1 is provided with a solenoid valve 101 and a pressure detection...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com