Steering machine for steering of paperboards

A steering machine and cardboard technology, applied in the field of steering machines, can solve the problems of increasing equipment costs, complicated structure of steering devices, etc., and achieve the effects of convenient maintenance, simple structure and fast steering speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

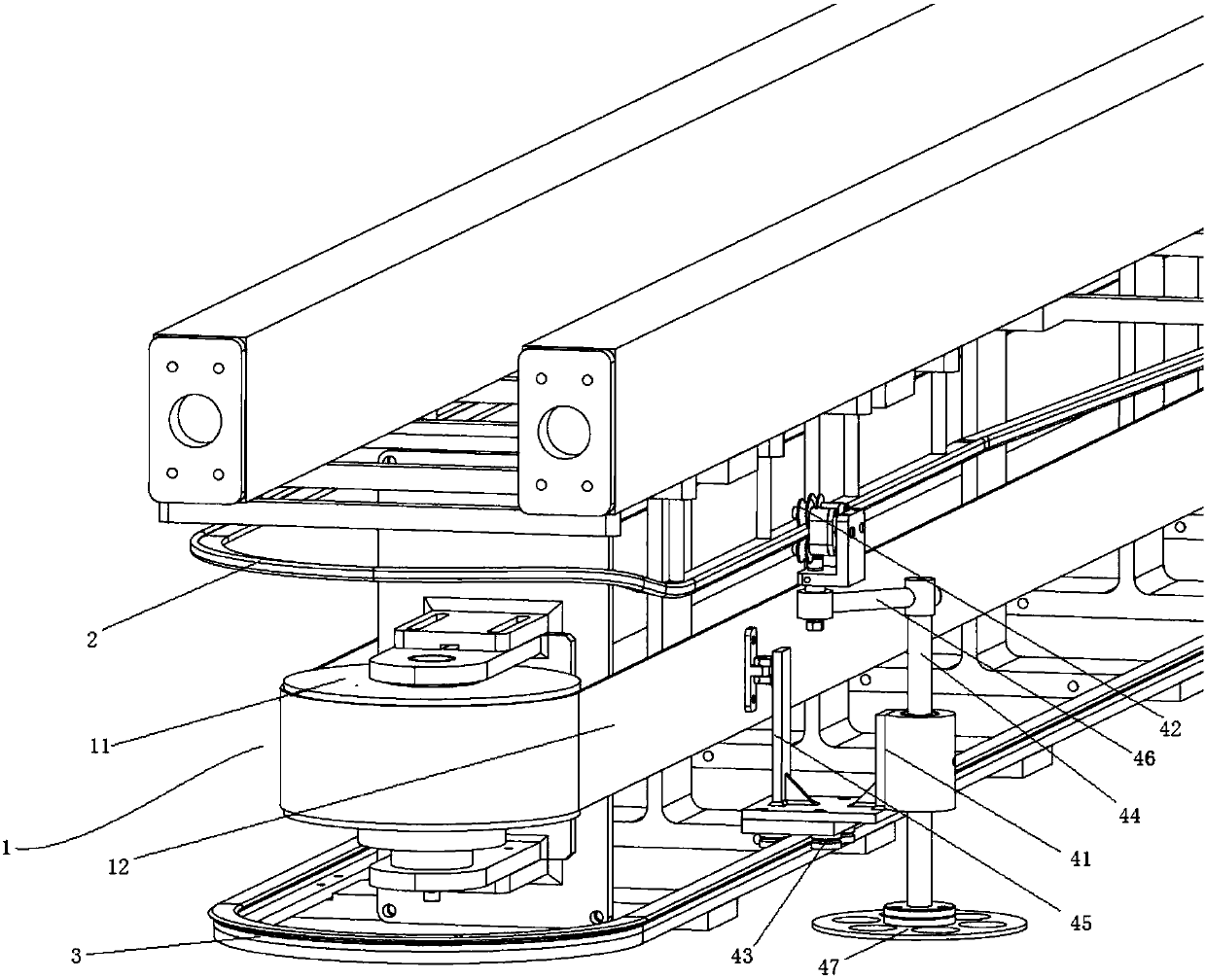

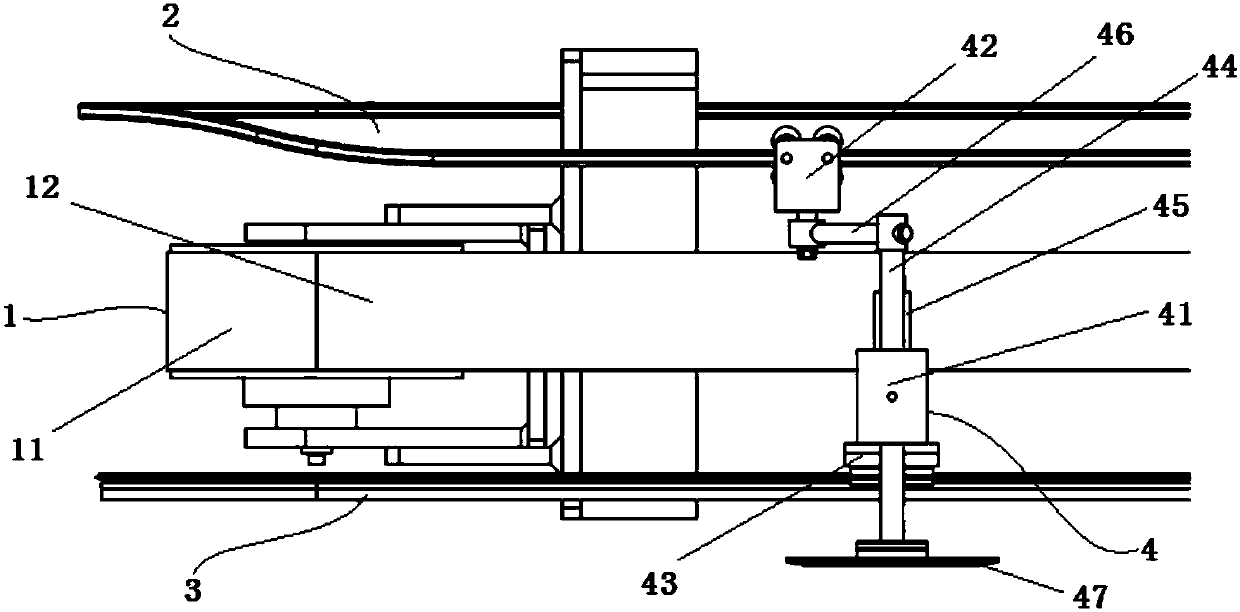

[0035] A kind of steering machine for cardboard steering, its structure is as follows figure 1 and figure 2 shown, including:

[0036] Transmission unit 1: including two runners 11, a belt 12 connected to the runners 11 and a motor that drives the runners 11 to rotate, the motor is not shown in the figure;

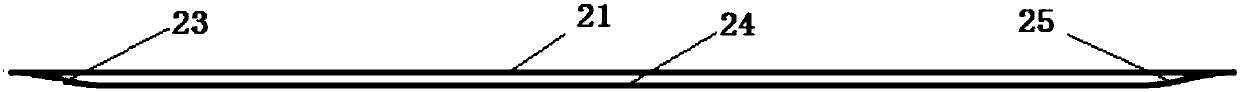

[0037] Special-shaped track 2: located above the transmission unit 1, including circularly linked straight track 21, small circular arc track 22, downward gradient track 23, folded track 24, upward gradient track 25, large circular arc track 26, and the structure of the special-shaped track Such as Figure 3a and Figure 3b As shown, wherein, the two ends of the straight rail 21 are respectively connected with the large arc rail 26 and the small arc rail 22, and the straight rail 21 is tangent to the large arc rail 26 and the small arc rail 22; the straight rail 21, the large arc rail Circular arc track 26 and small circular arc track 22 are on the same horizontal pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com