Hexahedron finite element grid partitioning method for simulating screw-thread fit

A grid division and hexahedron technology, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve problems such as complex methods, large amount of coordinate calculations, limited grid quality and simulation accuracy, and the accuracy of 3D models , to achieve the effect of improving accuracy and efficiency and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

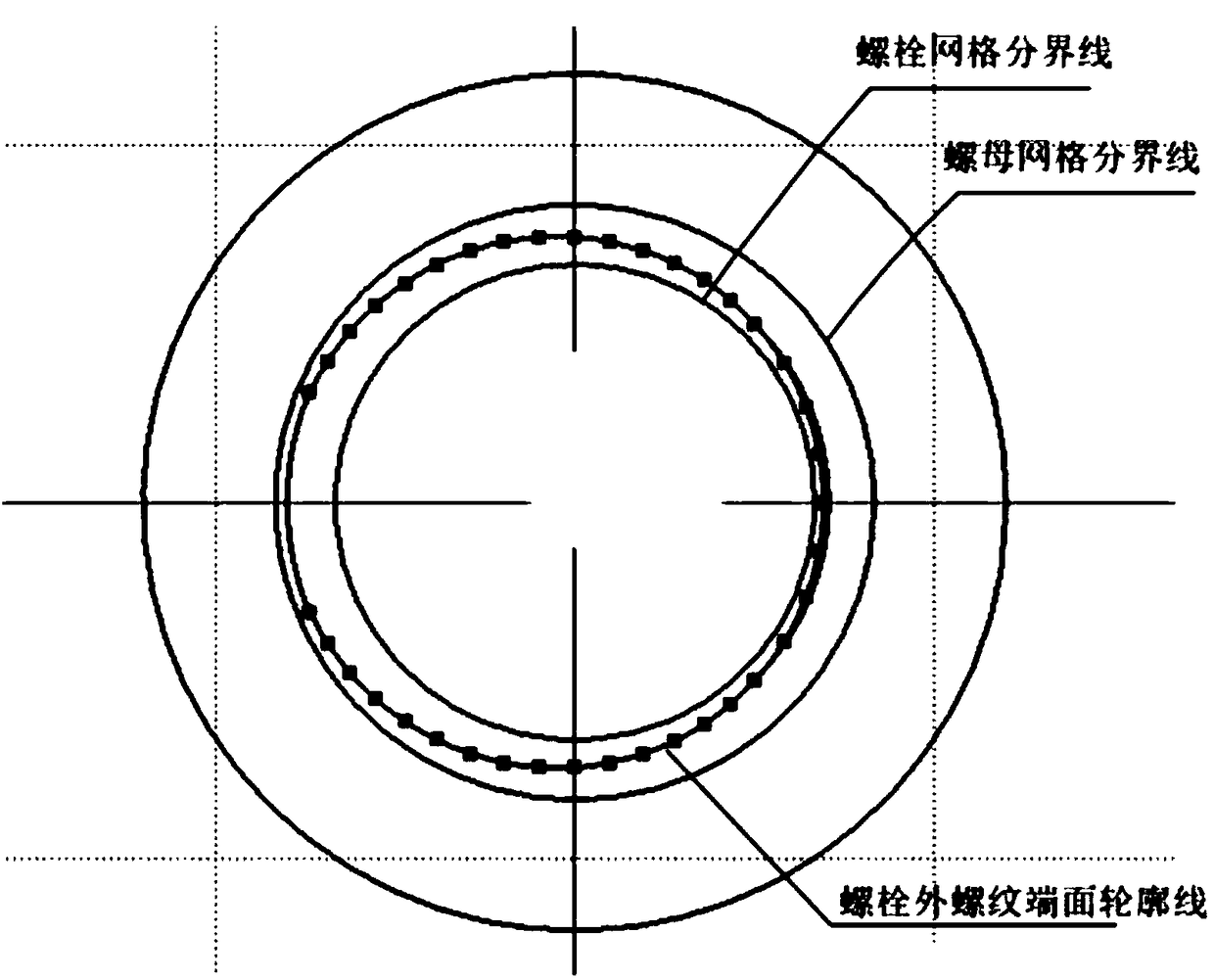

Image

Examples

Embodiment Construction

[0040] A hexahedron finite element mesh division method for simulating screw fitting involved in the present invention will be further described below in conjunction with the embodiments.

[0041] The bolts in this embodiment are right-handed bolts with M16×95, 8 total threads, 6 contact threads, and a pitch of 2.0000 mm. The present invention is described with the finite element analysis preprocessing software Hypermesh, and the steps are as follows:

[0042] figure 1 It is a schematic diagram of the structural dimensions in the axial cross-section of a pitch internal trapezoidal thread in an embodiment of the present invention.

[0043]Step 1, collect the structural dimensions in the axial cross-section of the internal thread of a pitch under the mating state of the bolt and the nut, such as figure 1 As shown, in this embodiment, the collected structural dimensions include the following: the nominal diameter of the thread is 16.0000mm, that is, the major diameter D of the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com