Rolling stock axle interference assembly contact stress analysis method based on simulation

A contact stress and analysis method technology, applied in computer-aided design, special data processing applications, instruments, etc., can solve the problems that the quality of the wheel set cannot be accurately predicted and measured, the analysis is limited, and the problem cannot be described.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Taking the research on contact stress of CRH2 type EMU trailer wheel pair axle interference assembly as an example, the present invention will be further described with reference to the accompanying drawings.

[0026] Such as figure 1 Shown is a working flow chart of the present invention based on the simulation method for analyzing the contact stress of the railway locomotive vehicle axle interference assembly contact stress. The detailed steps are as follows:

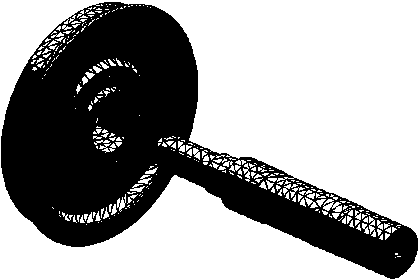

[0027] Step 1: The three-dimensional model of wheel and axle interference transfer, using SolidWorks to establish three-dimensional digital models of the wheels and axles of railway locomotives, and complete their virtual assembly. At the same time, the model is simplified, simplified to a wheel and half axle mode, and some small rounded corners and small chamfers are omitted, such as figure 2 shown;

[0028] Step 2: Transfer the finite element model of the wheel shaft interference fit, transfer the 3D mode...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com