Seawater-electrolyzing chlorine-producing antifouling method

A seawater and antifouling technology, applied in electrolytic components, electrolytic processes, cells, etc., can solve problems such as hydrogen enrichment, potential differences in piping systems, and potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

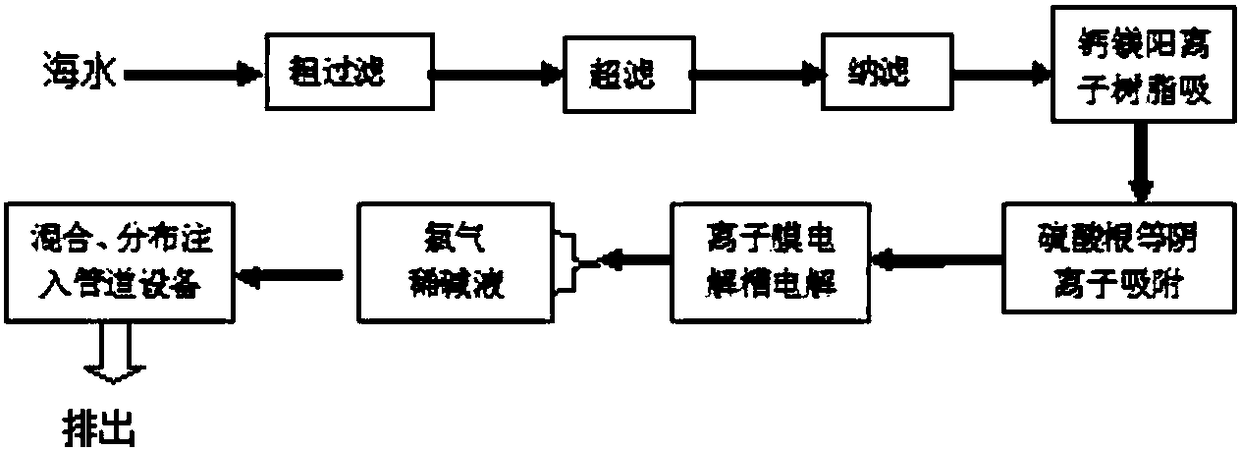

[0028] Seawater is first coarsely filtered to remove impurity particles larger than 5 microns in the water. Secondly, through the ultrafiltration membrane module, the micron-sized and colloidal substances in the seawater are further removed. Third, the pre-treated purified seawater passes through the nanofiltration membrane to remove calcium and magnesium ions, reducing the total concentration of calcium and magnesium ions to 500-600ppm, and then, using adsorption resin, further removes calcium and magnesium ions and sulfate radicals in seawater Anions and cations such as ions, so that the total concentration of calcium and magnesium ions in seawater is less than 100ppm. In this case, the content of sodium chloride in seawater is 2.0-2.5%.

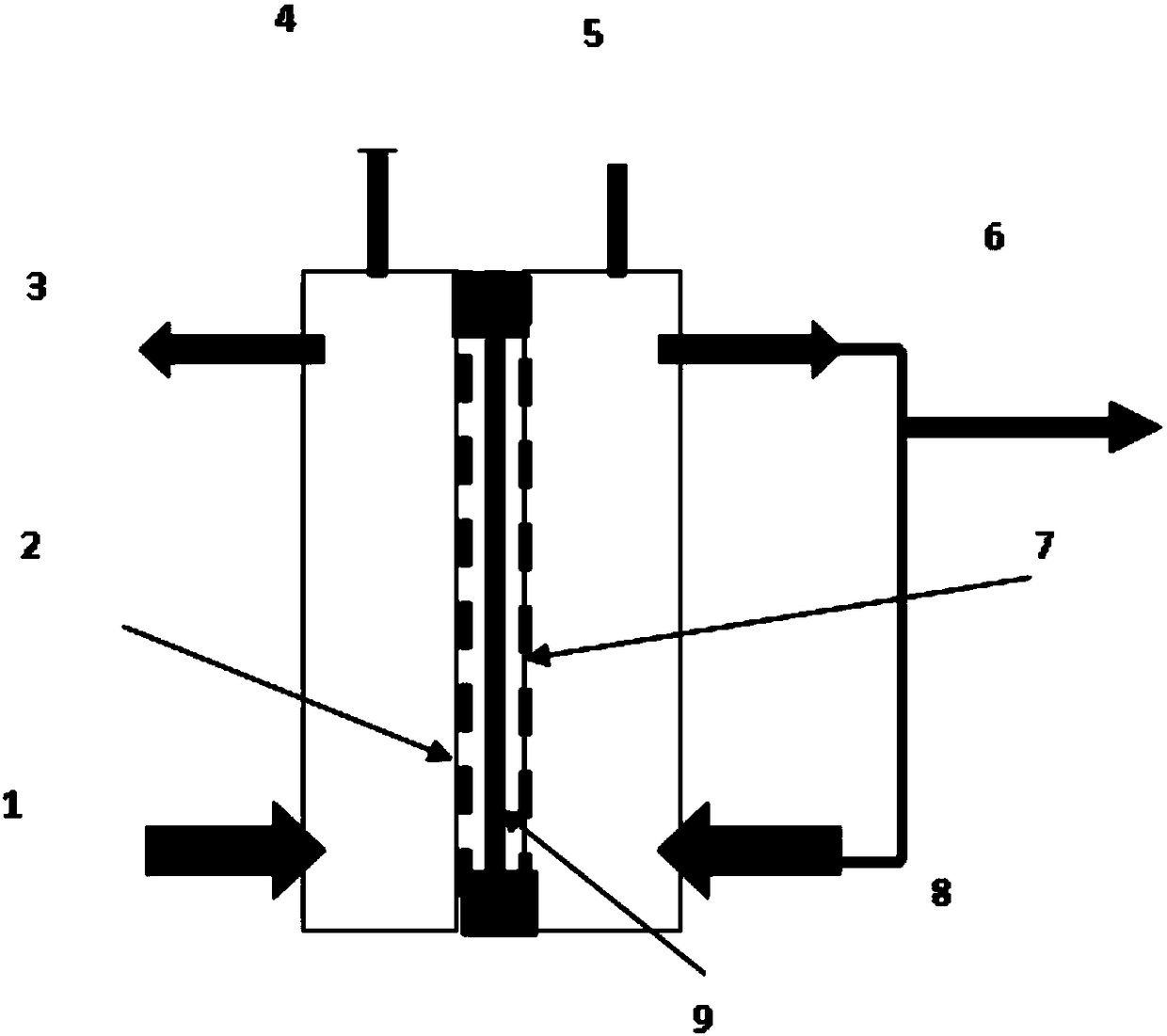

[0029] After the above-mentioned pretreated seawater enters the special seawater ion membrane electrolyzer for electrolysis. Seawater is electrolyzed to produce chlorine gas and dilute lye. Chlorine gas and dilute lye are mixed through a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com