Power cable winding device

A technology for wire collection equipment and power cables, applied in the field of wire collection equipment, can solve the problems of effective sorting, cable overheating failure, impossible old cables, etc., and achieves the effect of high practicability and improved recycling efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

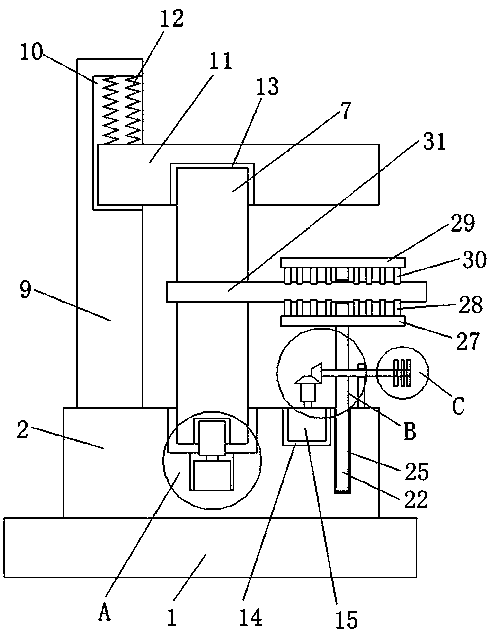

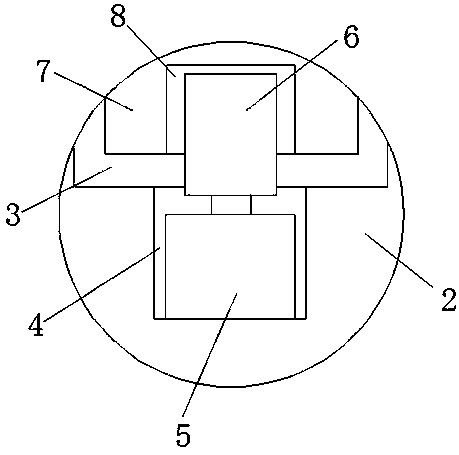

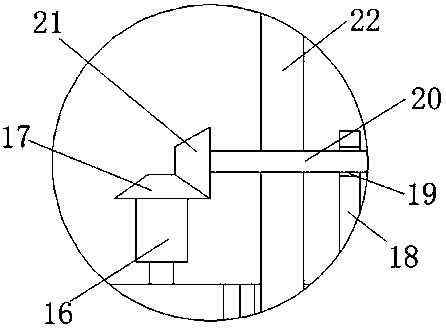

[0026] refer to Figure 1-5In this embodiment, a power cable take-up device is proposed, including an electronic weighing pan 1, a placement seat 2 is fixedly installed on the top of the electronic weighing pan 1, and a placement slot 3 is provided on the top of the placement seat 2, and a placement slot 3 is provided on the bottom inner wall of the placement slot 3. A first installation groove 4 is provided, and a drive motor 5 is installed in the first installation groove 4. A screw rod 6 is welded on the output shaft of the drive motor 5. A drum 7 is arranged above the drive motor 5, and the bottom end of the drum 7 is opened. Threaded groove 8 is arranged, and screw rod 6 is threadedly connected with threaded groove 8, and the top of rotating drum 7 extends to the top of placing seat 2, and the top side of placing seat 2 is welded with vertical plate 9, and vertical plate 9 is close to the bottom of rotating drum 7. A side top is provided with a sliding groove 10, and a sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com