Double-opening sealing cover

A technology for closing caps and bottom caps, which is applied in the field of bottle caps of containers, can solve problems such as easy loss of top caps, easy entry of external pollutants into the bottle, easy breakage of flexible connectors, etc., to avoid pollution, simple structure, easy bubble effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

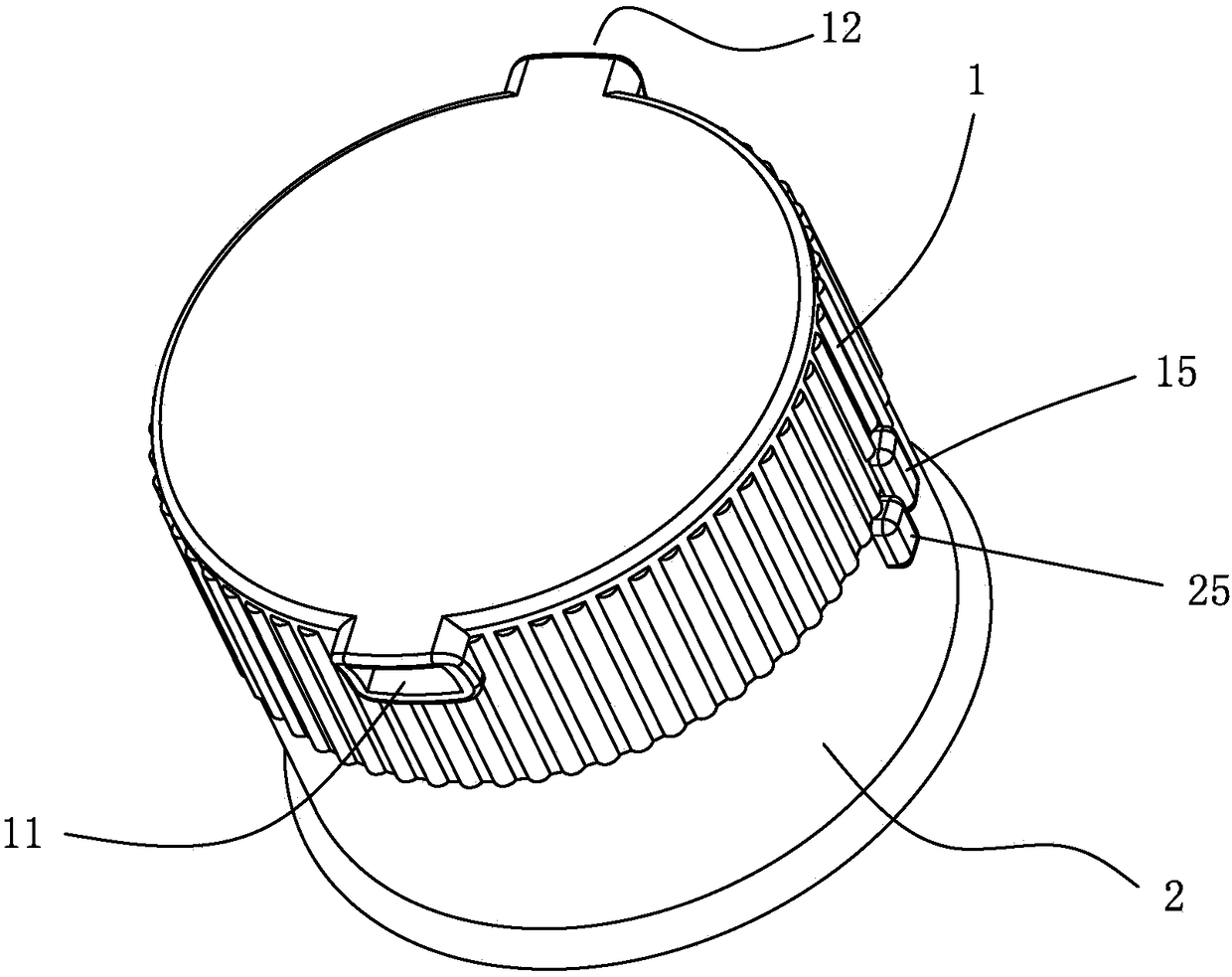

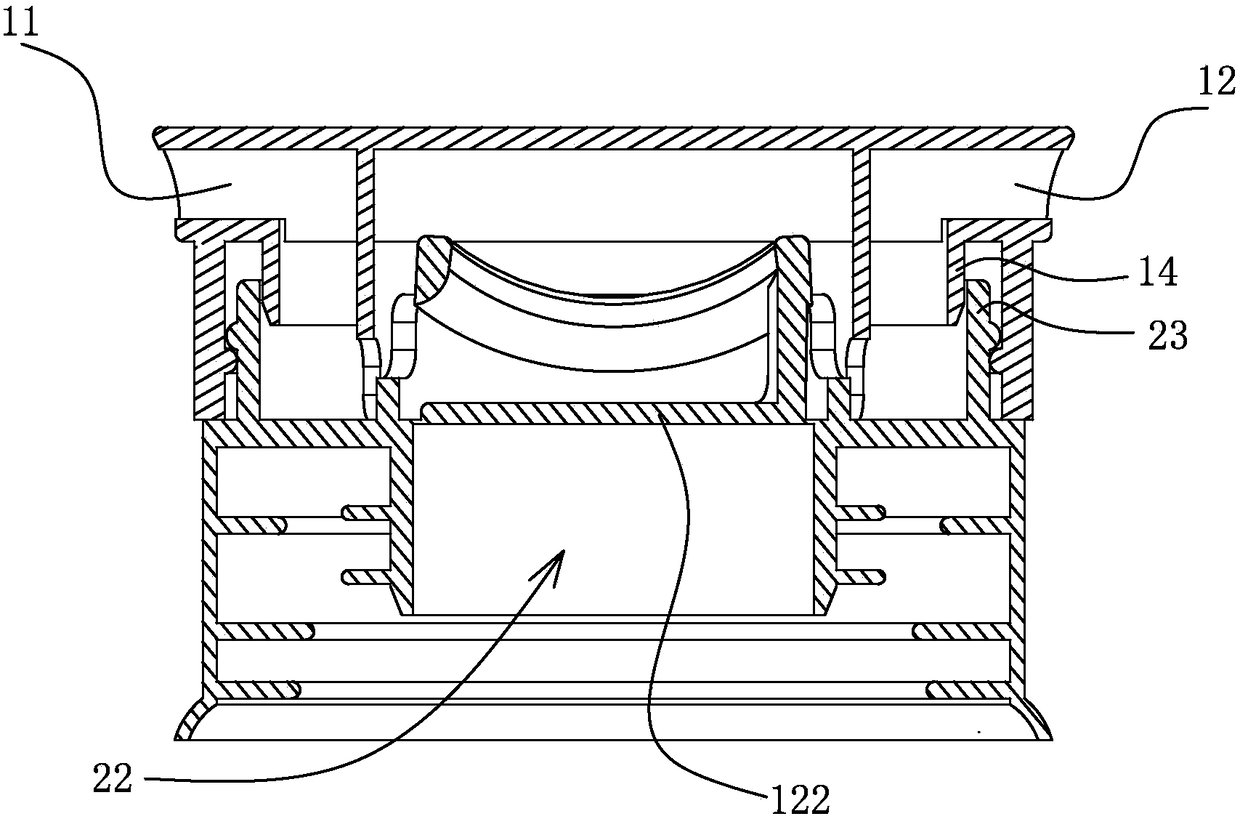

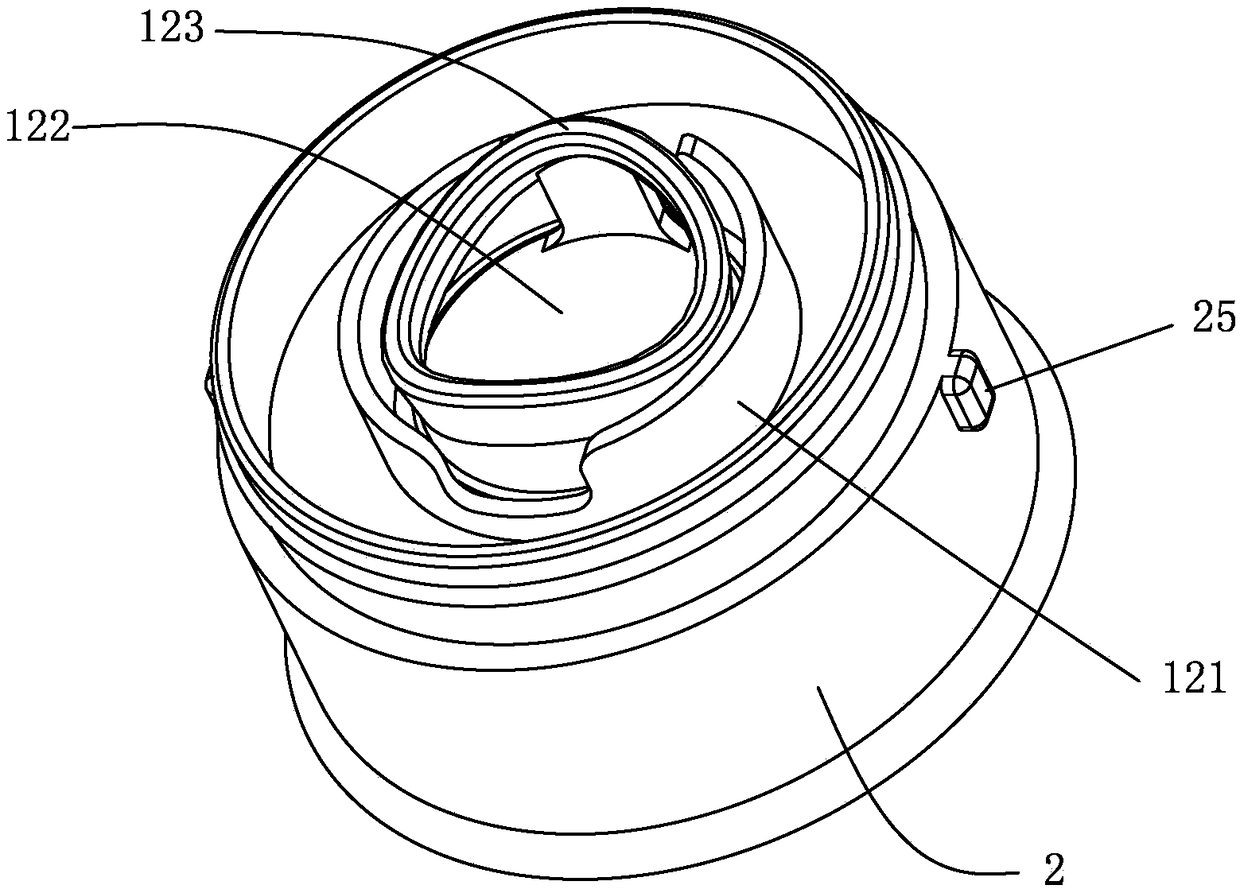

[0043] like Figure 1 to Figure 6 As shown, a double-port closure in this embodiment includes an upper cover 1 and a bottom cover 2, the bottom cover 2 has upper and lower openings that can communicate, and the upper cover 1 is rotatably connected to the top of the bottom cover 2. Opening 21, the lower opening 22 of the bottom cover 2 is connected to the container mouth, the upper cover 1 is provided with an air inlet 11 and a liquid outlet 12, correspondingly, the bottom cover 2 is provided with a conduction outlet Liquid structure, when the upper cover 1 is turned, the liquid outlet structure can make the air inlet 11 and the liquid outlet 12 communicate with the upper opening 21 of the bottom cover 2 at the same time, and in the initial state, the upper opening 21 of the bottom cover 2 is connected to the air inlet Port 11 and liquid outlet 12 are hermetically isolated. In the present invention, an air inlet 11 and a liquid outlet 12 are arranged on the upper cover 1, and ...

Embodiment 2

[0052] Such as Figure 7 to Figure 12 As shown, a double-port closure in this embodiment includes an upper cover 1 and a bottom cover 2, the bottom cover 2 has upper and lower openings that can communicate, and the upper cover 1 is rotatably connected to the top of the bottom cover 2. Opening 21, the lower opening 22 of the bottom cover 2 is connected to the container mouth, the upper cover 1 is provided with an air inlet 11 and a liquid outlet 12, correspondingly, the bottom cover 2 is provided with a conduction outlet Liquid structure, when the upper cover 1 is turned, the liquid outlet structure can make the air inlet 11 and the liquid outlet 12 communicate with the upper opening 21 of the bottom cover 2 at the same time, and in the initial state, the upper opening 21 of the bottom cover 2 is connected to the air inlet Port 11 and liquid outlet 12 are hermetically isolated.

[0053] The difference between this embodiment and Embodiment 1 is mainly that the specific structu...

Embodiment 3

[0058] Such as Figure 13 to Figure 18 As shown, a double-port closure in this embodiment includes an upper cover 1 and a bottom cover 2, the bottom cover 2 has upper and lower openings that can communicate, and the upper cover 1 is rotatably connected to the top of the bottom cover 2. Opening 21, the lower opening 22 of the bottom cover 2 is connected to the container mouth, the upper cover 1 is provided with an air inlet 11 and a liquid outlet 12, correspondingly, the bottom cover 2 is provided with a conduction outlet Liquid structure, when the upper cover 1 is turned, the liquid outlet structure can make the air inlet 11 and the liquid outlet 12 communicate with the upper opening 21 of the bottom cover 2 at the same time, and in the initial state, the upper opening 21 of the bottom cover 2 is connected to the air inlet Port 11 and liquid outlet 12 are hermetically isolated.

[0059] The difference between this embodiment and Embodiment 1 is mainly that the specific struct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com