Long-rod-shaped workpiece clamping device

A clamping device, long rod-shaped technology, applied in metal processing, manufacturing tools, metal processing equipment, etc., can solve problems such as reducing production efficiency and increasing labor intensity of staff

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

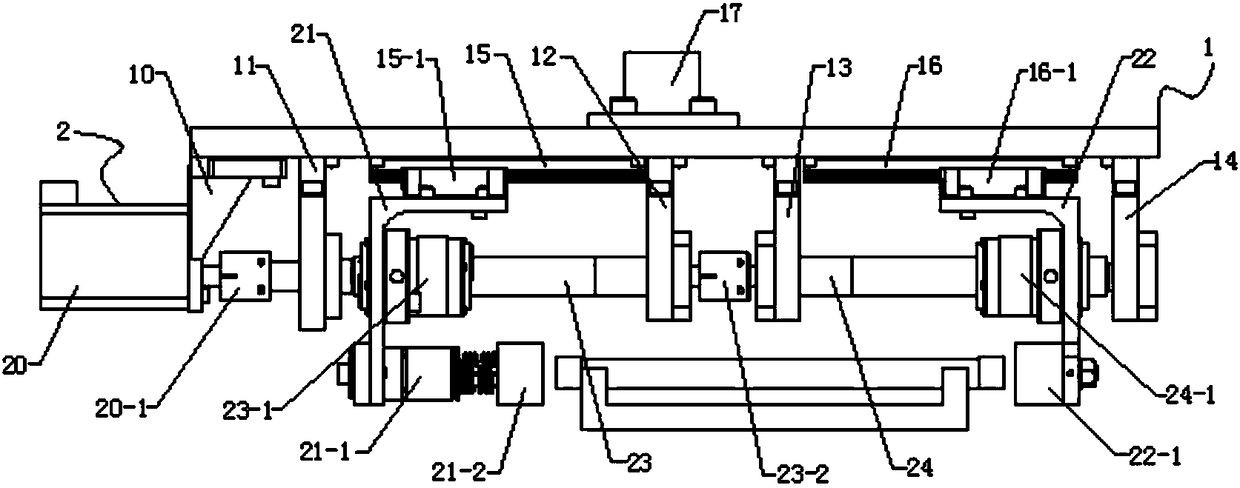

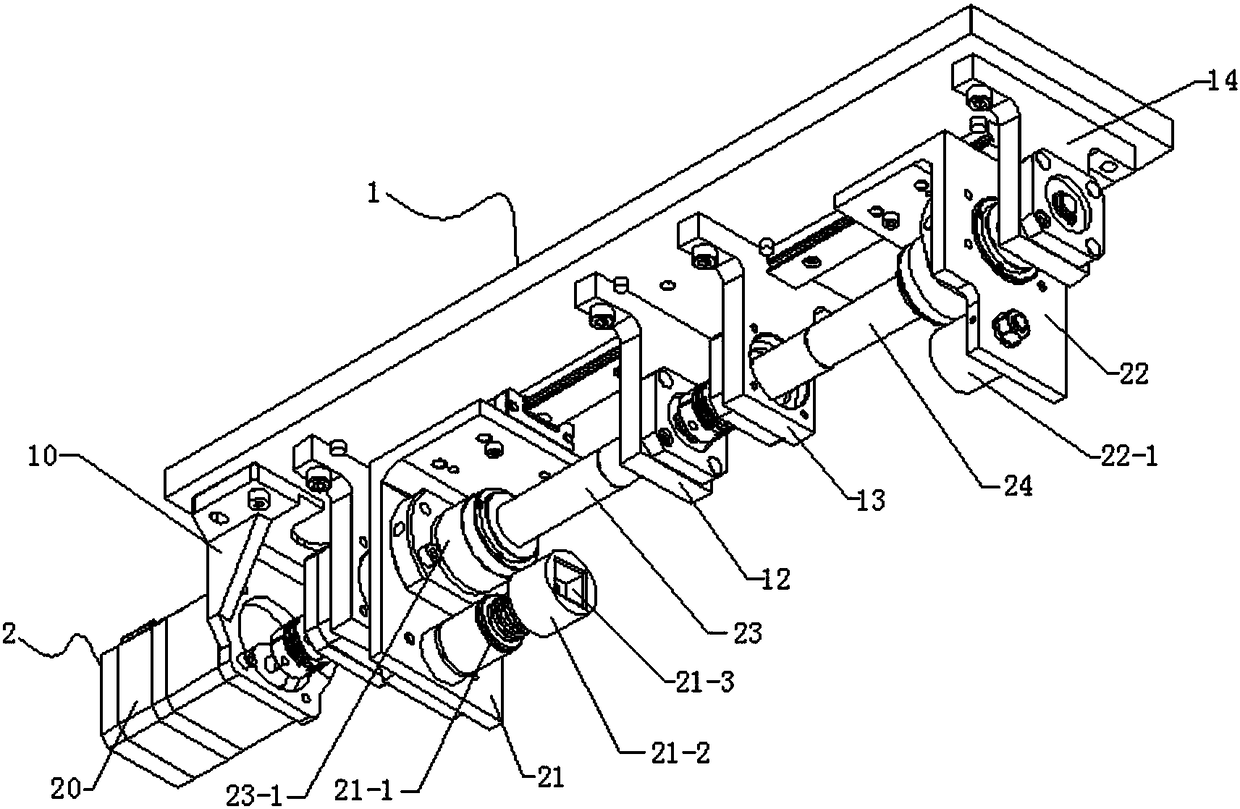

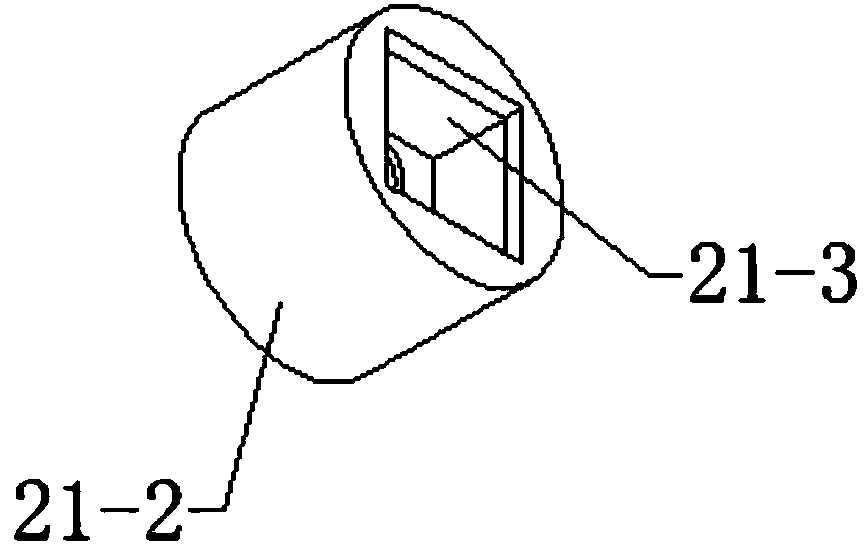

[0024] This invention drives the left-handed screw rod 23 to rotate through the motor 20, and the left-handed screw rod 23 has a screw block one 23-1 matched therewith, so that the screw block one 13-1 reciprocates on the left-hand screw rod 23, and the screw block one 23 -1 drives the clamp seat 21 on it, and the clamp seat 21 is fixedly connected with the slider 15, so that the clamp seat 21 moves back and forth on the slide rail 15 to move and clamp, and the right-hand thread screw rod 24 passes through the coupling 2 23-2 is fixedly connected with the left-hand threaded screw rod 23, and the right-handed threaded screw rod 24 has a screw block two 24-1 matched therewith, and the screw block two 24-1 drives the clip seat two 22 to reciprocate on the slide rail two 16, and the left-hand The threaded screw rod 23 and the right-handed threaded screw rod 24 rotate synchronously, but the threads of the two are different, so that the first clamping seat 21 and the second clamping ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com