Device for achieving checking and laser adjusting on rollers and guide template and application method

A guide board and laser technology, applied in the field of guides, can solve the problems of long adjustment of rolls and guide boards, cumbersome production of wax paper guide templates, time-consuming and laborious problems, etc., to improve production efficiency, shorten production time, and operate convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are explanations of the present invention and the present invention is not limited to the following examples.

[0030] Example.

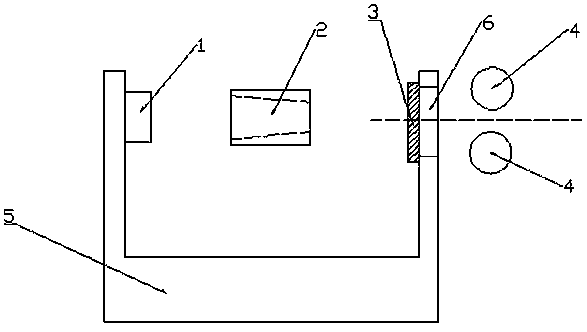

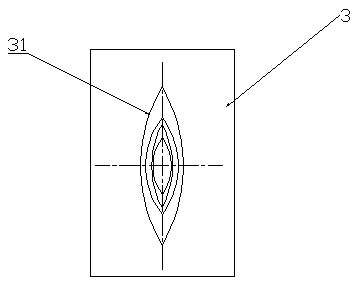

[0031] see Figure 1 to Figure 2 , a calibration laser adjustment roll guide template device, including a laser bracket, laser 1 and a drawing 3 printed with a standard guide outlet size pattern 31, the laser bracket is composed of a laser mounting plate 51, a base 50 and a drawing mounting plate 52.

[0032] The base 50 is a cuboid, and the bottom end of the base 50 is provided with pulleys to facilitate the movement of the laser bracket.

[0033] A plurality of standard guide and guard outlet size patterns 31 can be printed on a drawing 3, and there are a plurality of standard guide and guard outlet size patterns 31 that are concentric and coaxial.

[0034] The laser mounting plate 51 is vertic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com