Special lifting device for rectangular steel plate

A technology of rectangular steel plates and spreaders, applied in the direction of load hanging elements, transportation and packaging, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

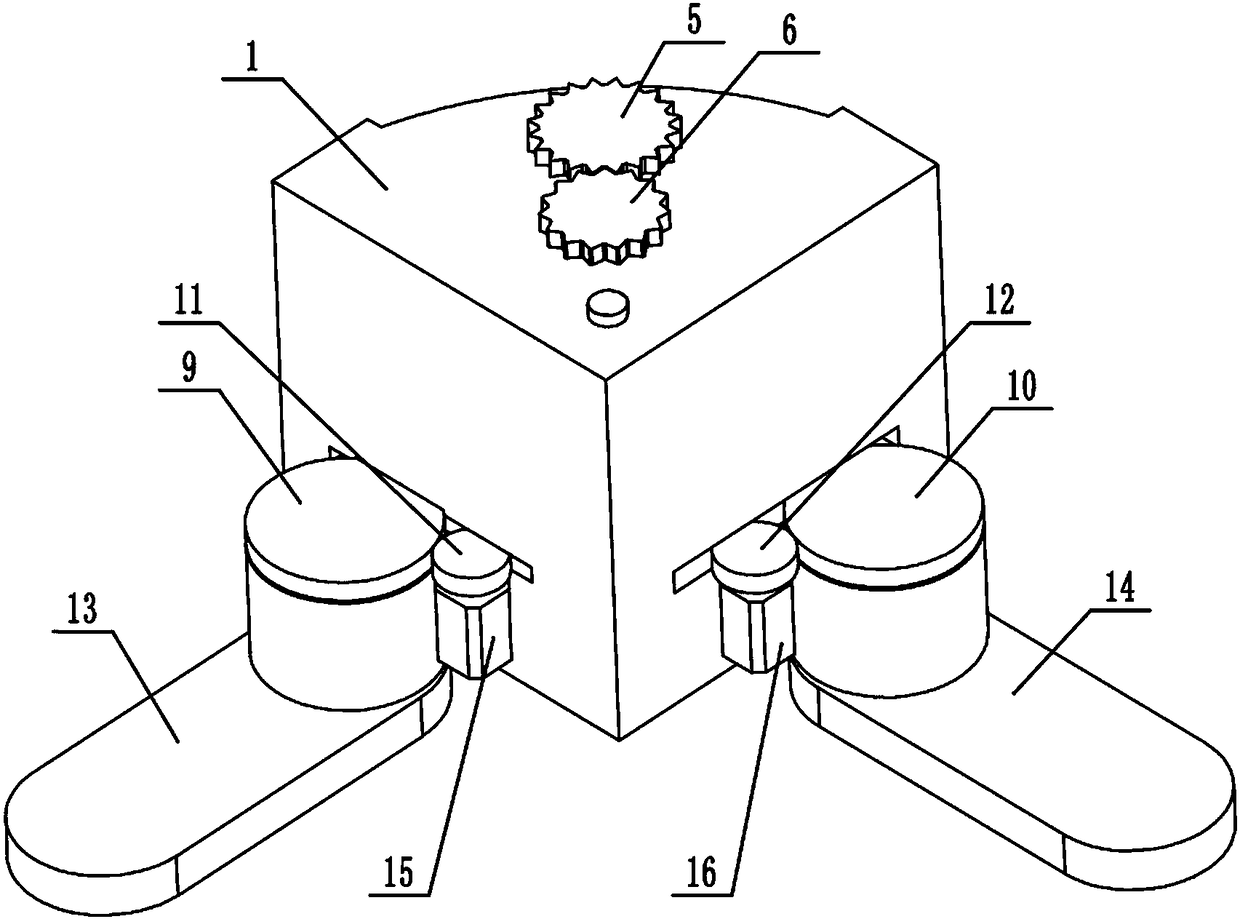

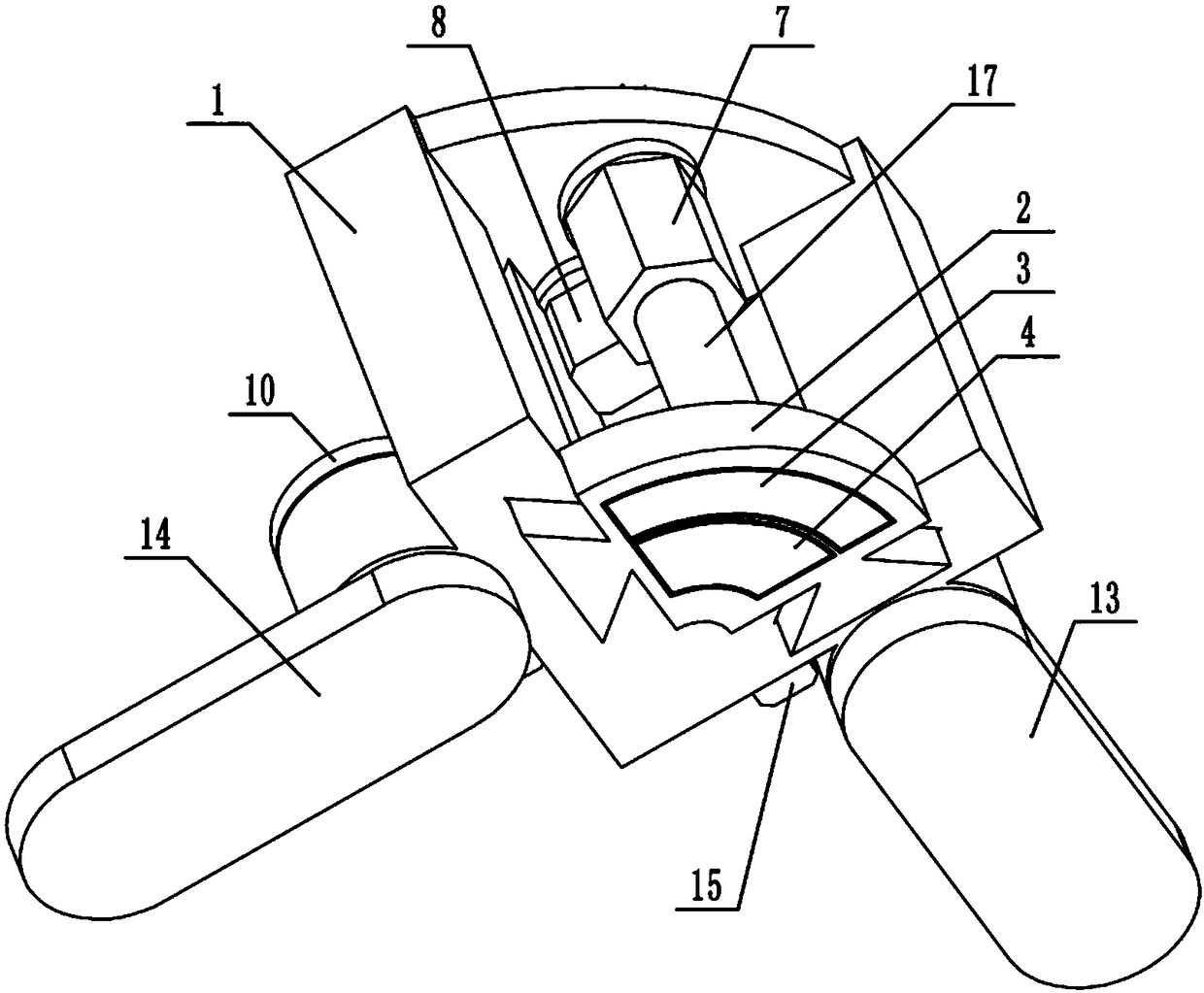

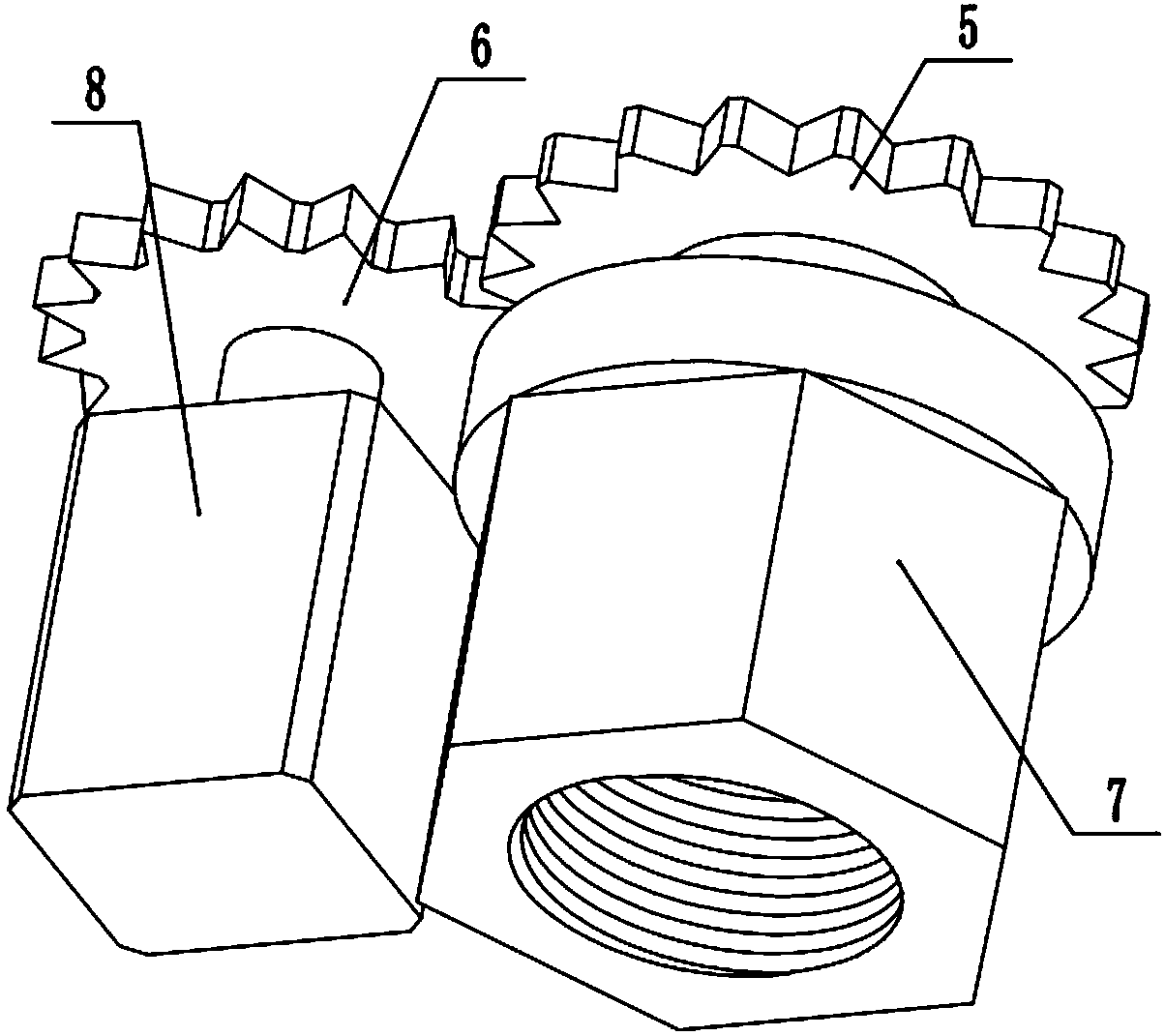

[0018] A special hanger for rectangular steel plates is composed of a frame 1, a pressure plate 2, a first electromagnet 3, a second electromagnet 4, a first driven gear 5, a first driving gear 6, a first lead screw slider 7, First motor 8, first driven round wheel 9, second driven round wheel 10, first driving round wheel 11, second driving round wheel 12, first supporting plate 13, second supporting plate 14, second motor 15. The third motor 16, the first lead screw 17, the first housing 18, the second housing 19, the third housing 20 and the suspension ring 21, the frame 1 structurally includes the main frame 101, the first installation Hole 102, Second Mounting Hole 103, First Dovetail Groove 104, Second Dovetail Groove 105, Third Mounting Hole 106, Fourth Mounting Hole 107, Rack Upper Surface 108, Ring Lug 109, Rack Inner Facade 110 , the first circular wheel groove 111, the second circular wheel groove 112, the first outer surface 113 of the frame and the second outer su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com