Substrate protective film and preparation method thereof, substrate and preparation method of display panels

A display panel and manufacturing method technology, applied to chemical instruments and methods, other household appliances, identification devices, etc., can solve problems such as low attachment efficiency, flexible substrate wrinkles, and incomplete removal of protective film, etc., to improve attachment efficiency , to avoid the effect of wrinkles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] In order for those skilled in the art to better understand the technical solution of the present invention, the substrate protection film provided by the present invention and its manufacturing method, the manufacturing method of the substrate and the display panel will be described in detail below with reference to the accompanying drawings.

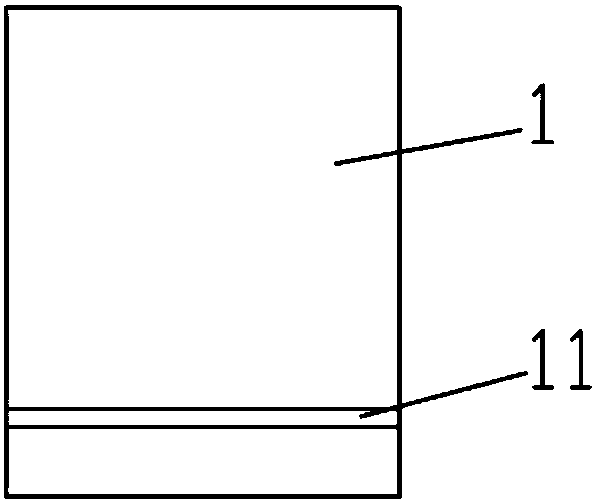

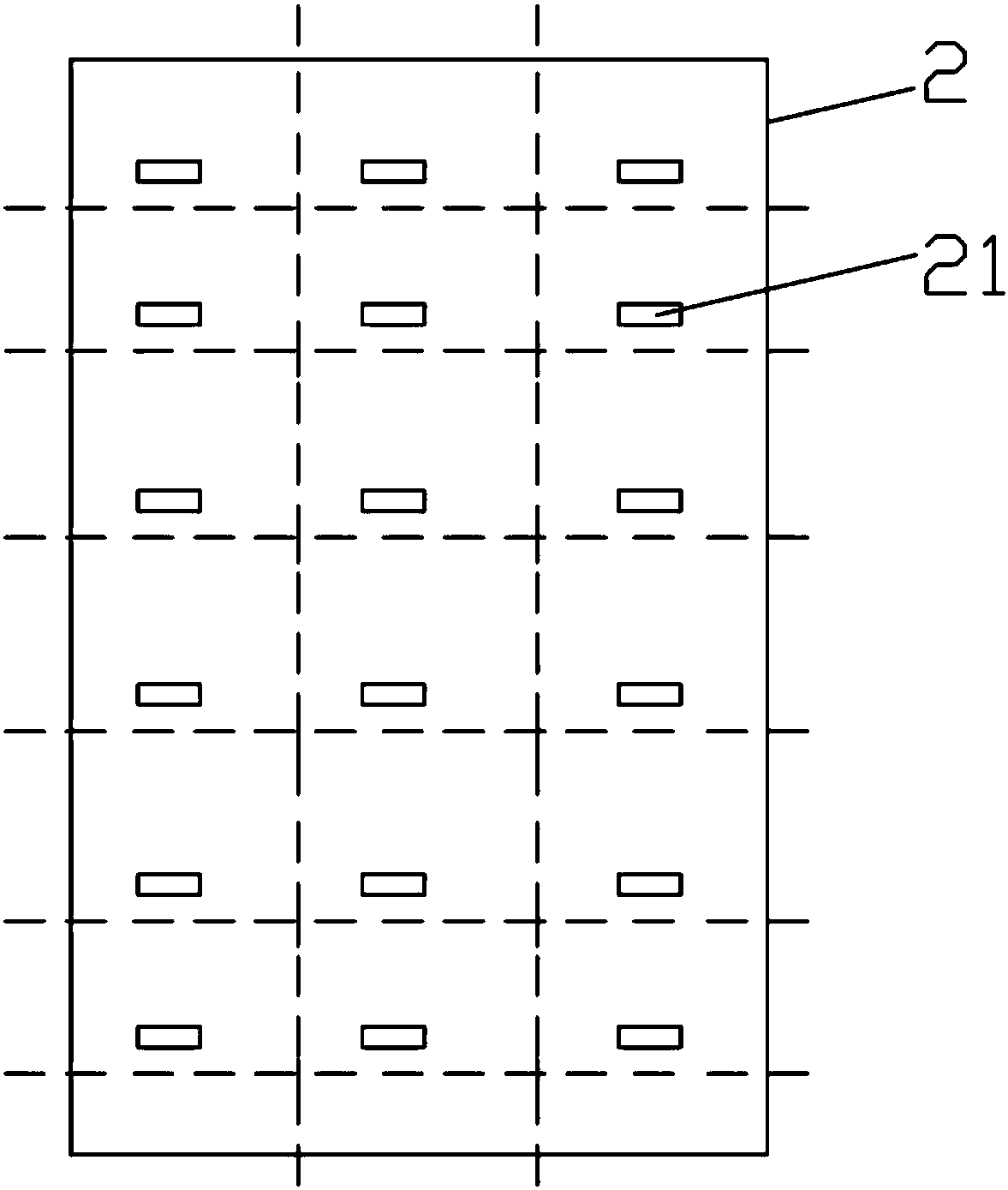

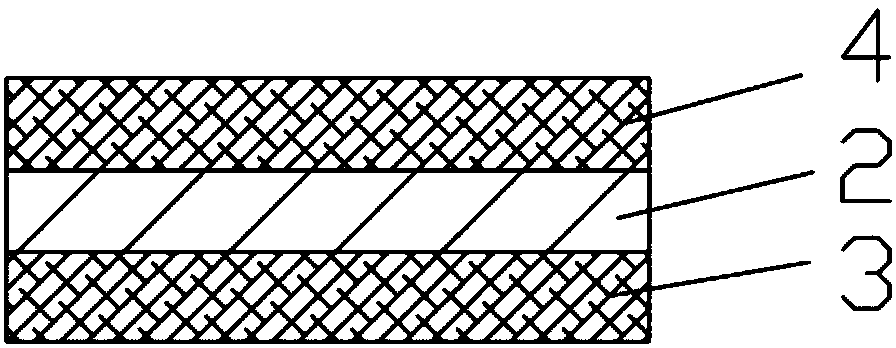

[0043] see figure 2 , the substrate protection film provided by the first embodiment of the present invention protects the substrate by attaching the protection film to the back surface of the substrate. The substrate is, for example, a flexible substrate. The substrate is usually large in size, and multiple independent small-size display panels can be obtained by cutting the large-size substrate. Specifically, the substrate includes a plurality of panel areas, and the plurality of panel areas correspondingly form a plurality of display panels; and each panel area has a first area, and the first area corresponds to a bending ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com