Mast verticality adjustment control method and device

A control method and mast technology, which are applied to support devices, control using feedback, and earth-moving drilling and mining, etc., can solve problems such as hidden dangers, mast shaking back and forth, and re-update, etc., to achieve the effect of strong adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

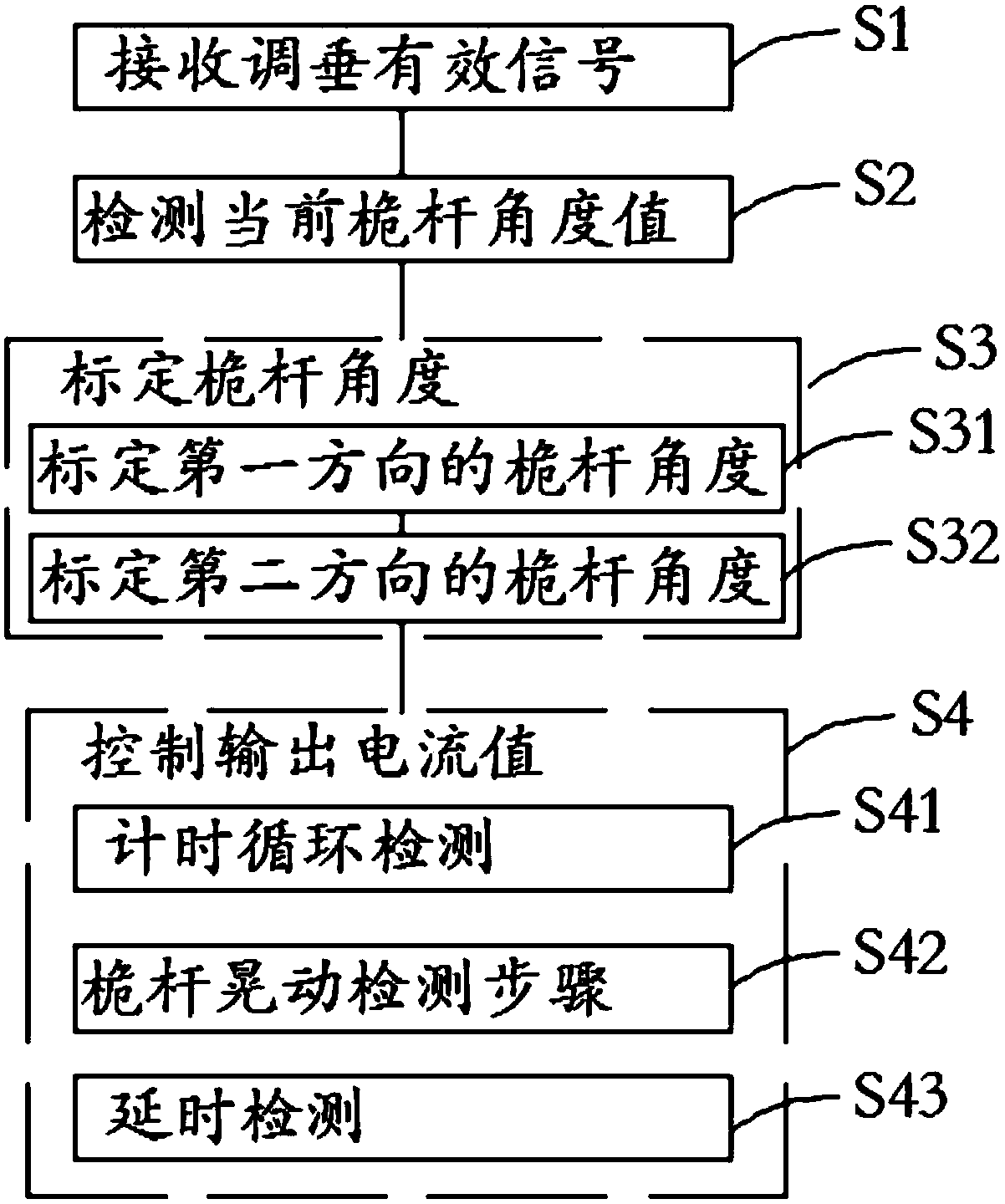

[0042] figure 1 This is a block diagram of the operation steps of the mast vertical adjustment control method provided by the first embodiment of the present invention, please refer to figure 1 .

[0043] The mast vertical adjustment control method provided in this embodiment includes the following steps:

[0044] S1: Receive the effective signal of vertical adjustment. The effective sag adjustment signal is issued by the operating switch and transmitted to the controller. After the controller receives the effective sag adjustment signal, the mast sag adjustment control device enters the sag adjustment mode and the sag adjustment function is turned on.

[0045] S2: Detect the current mast angle value. The angle of the mast is detected in real time by the inclination sensor. The inclination sensor sends the current mast angle to the controller.

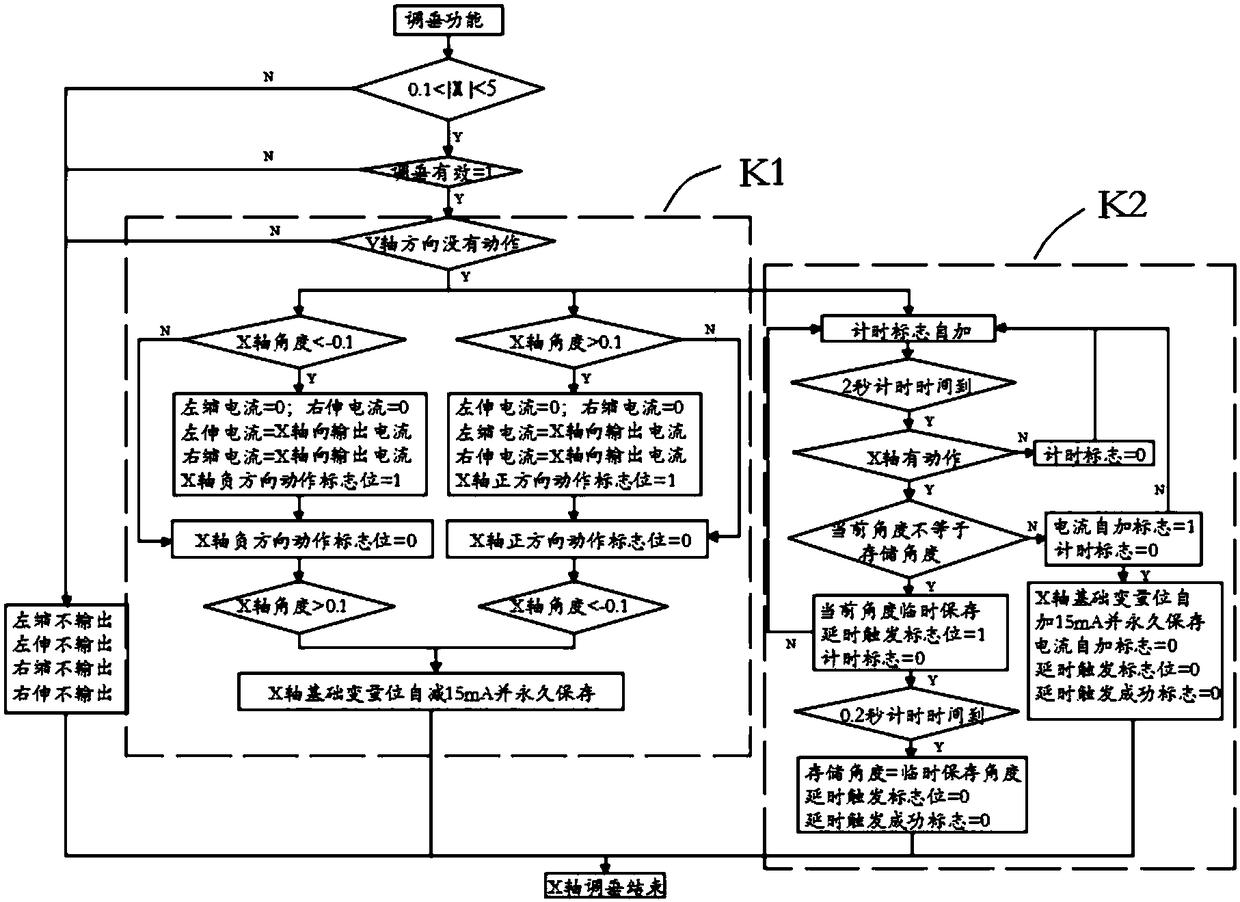

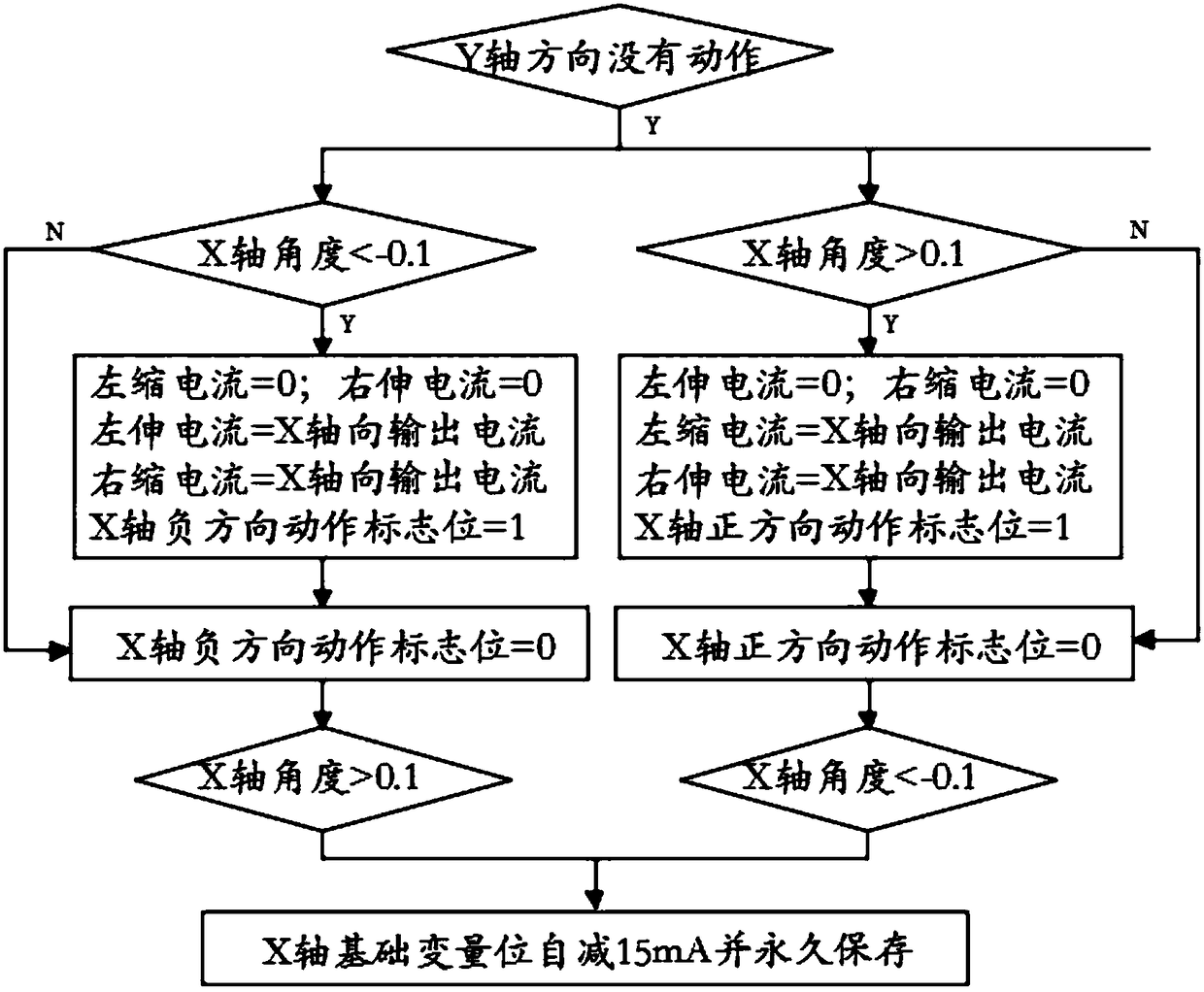

[0046] S3: Calibrate the mast angle. According to the current mast angle value, judge whether it is within the adjustable range of sag adj...

no. 2 example

[0079] The mast drooping control device provided in this embodiment includes a controller, an operation switch, an inclination sensor, a display, and an electric control valve group. The controller is connected to the operation switch, an inclination sensor, the display, and the electric control valve group, respectively.

[0080] The operating switch is used to send a sag signal to the controller. The tilt sensor is used to detect the mast angle. The controller selects the current output parameter from the preset current parameter curve according to the mast angle detected by the tilt sensor, and controls the electric current according to the current output parameter. The output current value of the control valve group, the display is used to display the current angle of the mast and display current output parameters and other related information, and the electronic control valve group is used to adjust the mast angle until the mast angle is zero.

[0081] Specifically, the control...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com