Reverse marking device for box-type furnace production line

A production line and box-type furnace technology, applied to printing devices, measuring devices, typewriters, etc., can solve the problems of limited range of activities, large space occupation, large space, etc., to achieve convenient and flexible mechanism installation, simple and effective mechanism, and improve marking efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The principles and features of the present invention are described below in conjunction with examples, which are only used to explain the present invention and are not intended to limit the scope of the present invention.

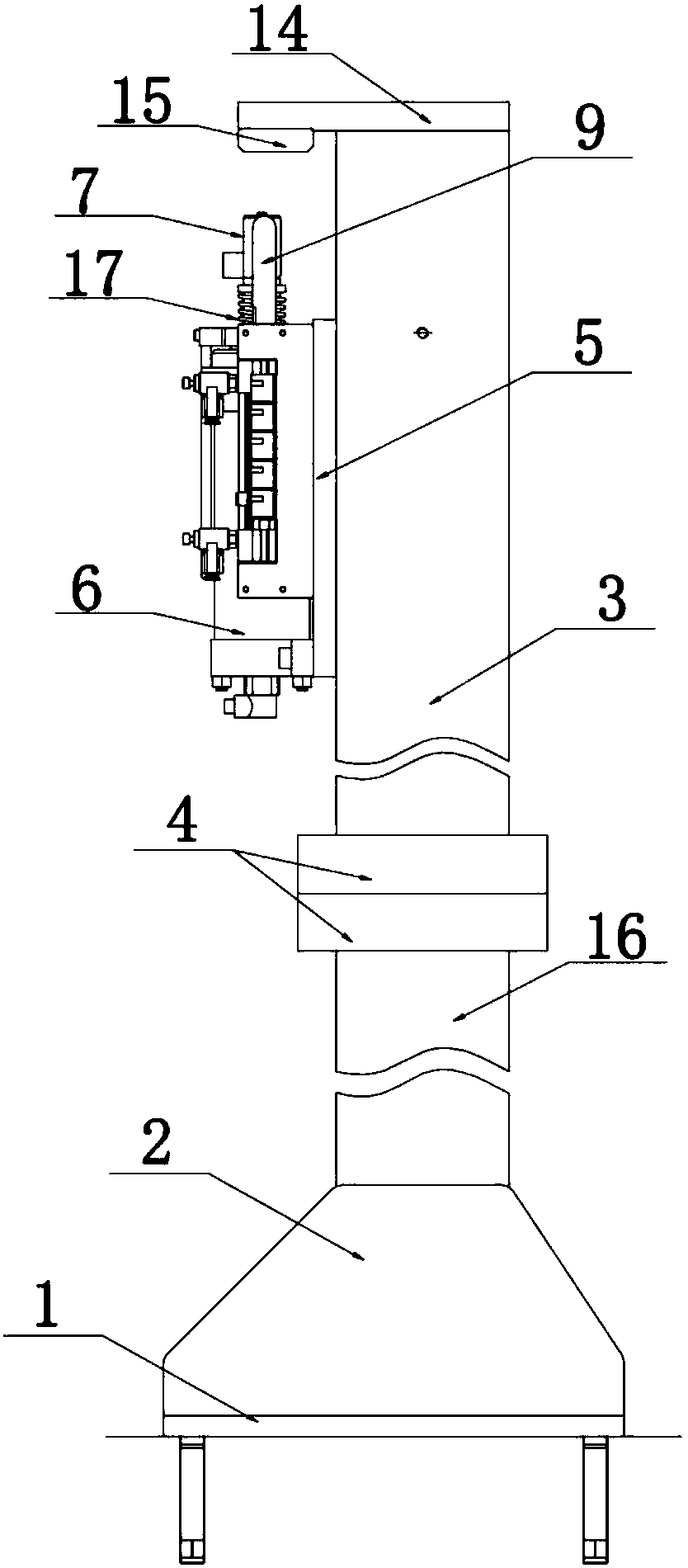

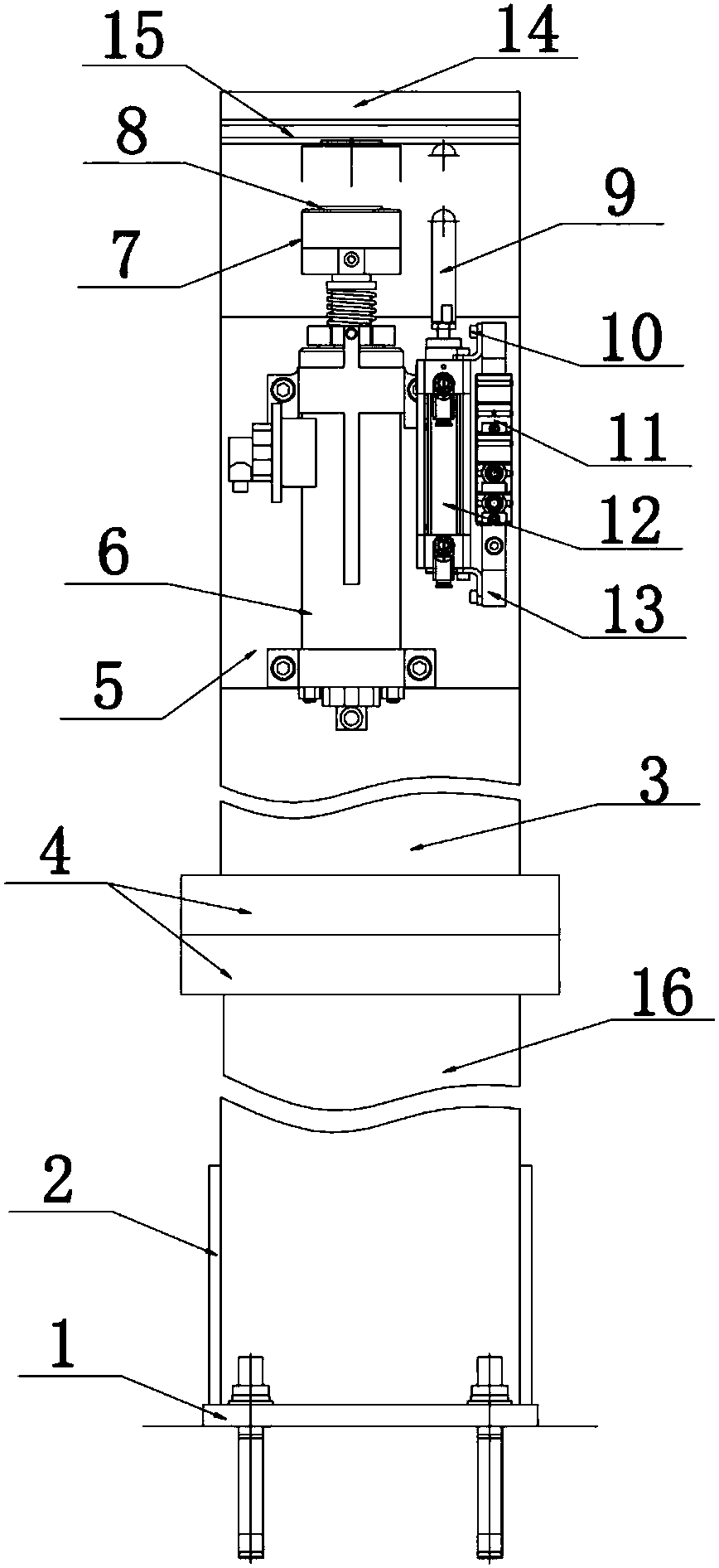

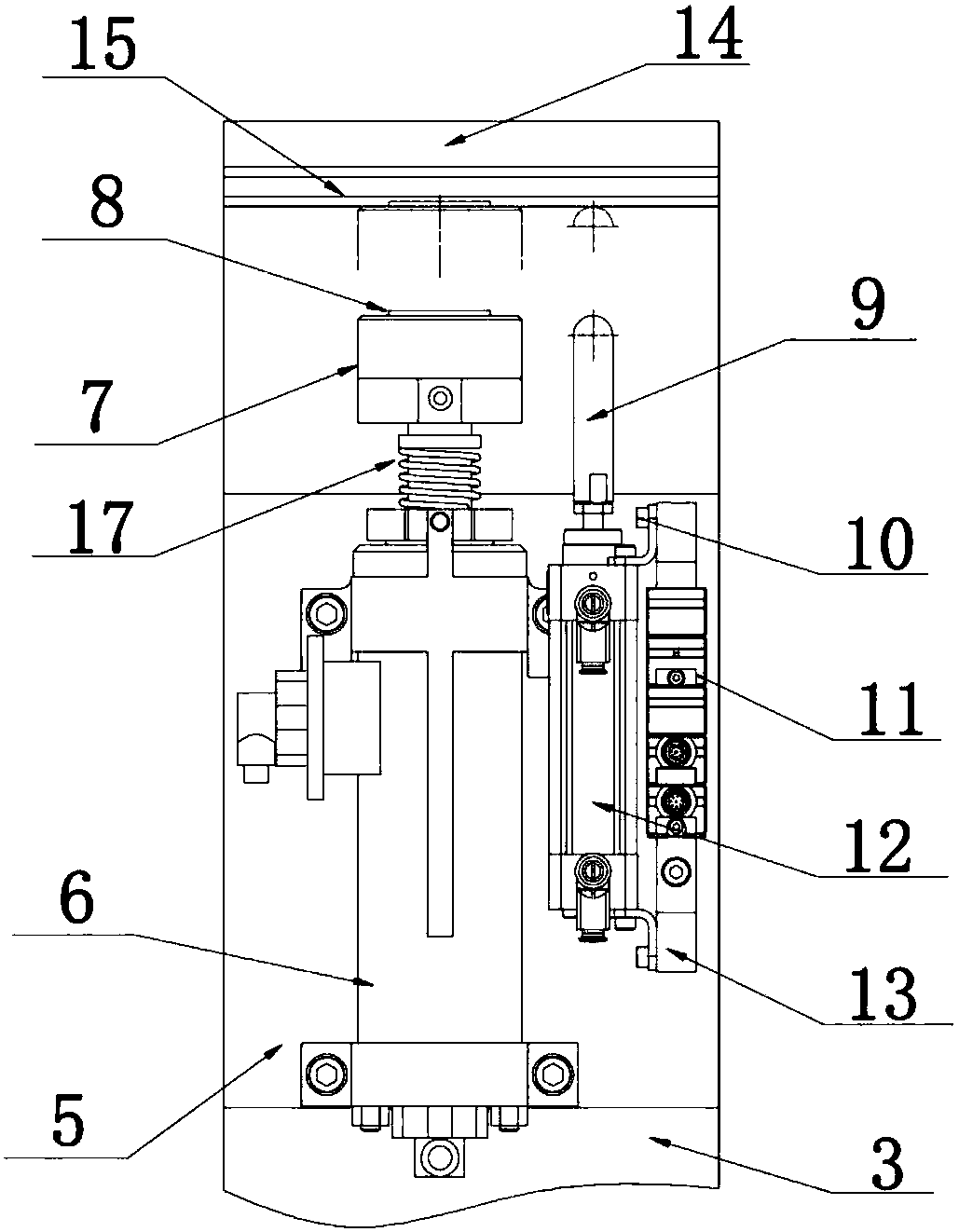

[0030] like Figure 1-Figure 4 As shown, a reverse marking device for a box furnace production line, including a column, a blank support mechanism arranged on the top of the column, a marking mechanism and a double blank detection mechanism arranged under the blank support mechanism;

[0031] The tablet support mechanism includes a marking table fixing seat 14 and a marking cutting board 15 arranged on the lower surface of the marking table fixing seat, and the marking table fixing seat is fixedly installed on the top of the column;

[0032] The marking mechanism includes an impact cylinder, 6 marking heads 7 and a word head 8 for printing marks, the marking head is connected with the piston rod of the impact cylinder, and the word head is arranged o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com