Soil remediation device capable of accurately regulating blanking efficiency

A soil remediation and accurate technology, applied in the field of soil remediation, can solve the problems of low soil remediation efficiency, difficult to transfer and use, equipment occupying a large space, etc., to achieve the effect of improving excavation efficiency, easy handling, and reducing storage space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

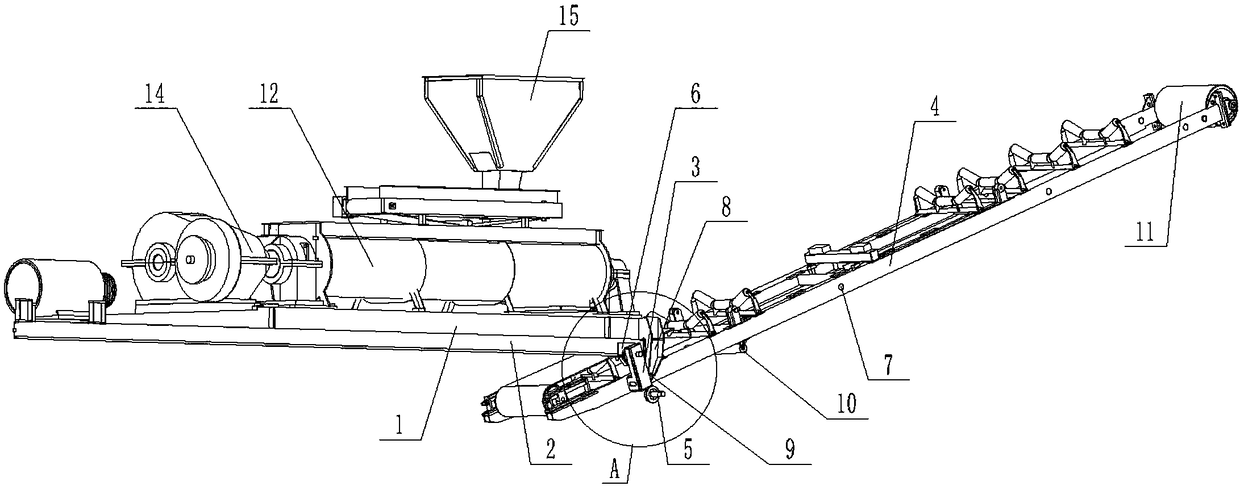

[0033] Such as Figure 1 to Figure 6 The shown soil remediation device capable of precisely controlling the feeding efficiency includes a platform body 1, the lower surface of the platform body 1 is a plane, a slideway 2 is arranged at the bottom of the platform body 1, and a first bearing is arranged on the slideway 2. A bearing can slide in the slideway 2, the first bearing is installed on the first bearing seat 3, and the first bearing seat 3 moves with the movement of the first bearing; the first bearing seat 3 and the linear transmission device 4 fixedly connected, the long axis of the linear transmission device 4 is coplanar with the long axis of the platform body 1; it also includes a support 5 connected to the lower end of the linear transmission device 4; a storage bin 12 is set on the platform body 1, and the A stirring shaft 13 is arranged in the storage bin 12, and a drive device 14 is arranged outside the storage bin 12, and the drive device 14 is used to drive th...

Embodiment 2

[0035] Such as Figure 1 to Figure 6 What is shown also includes a counterweight shaft 24 arranged on the elastic piece 21 , the counterweight shaft 24 is parallel to the rotating shaft 22 ; the upper edge of the transfer frame 20 is detachably connected to a baffle plate 25 . The aperture of the first through hole 28>the aperture of the second through hole 30; the gap between the upper surface of the baffle plate 27 and the lower surface of the upper partition plate 26 is 1 to 3 mm; The first through holes 28 are facing one by one. One end of the slideway 2 is provided with a positioning groove 6 , the positioning groove 6 is a trapezoidal structure with a large top and a small bottom, and the first bearing can move up and down in the positioning groove 6 . A number of first pin holes 7 are evenly distributed on the side of the linear transmission device 4, and a mounting block 8 is fixed at the end of the slideway 2, and a second pin hole 9 matching the first pin hole 7 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com