Non-heated rotary dehydration equipment

A dehydration equipment and rotary technology, applied in lighting and heating equipment, drying solid materials without heating, centrifuges, etc., can solve the problems of unsuitable materials heated by heating equipment, difficulty in quick operation, increased construction and manufacturing costs, etc. , to achieve the effect of saving construction cost, improving performance and saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

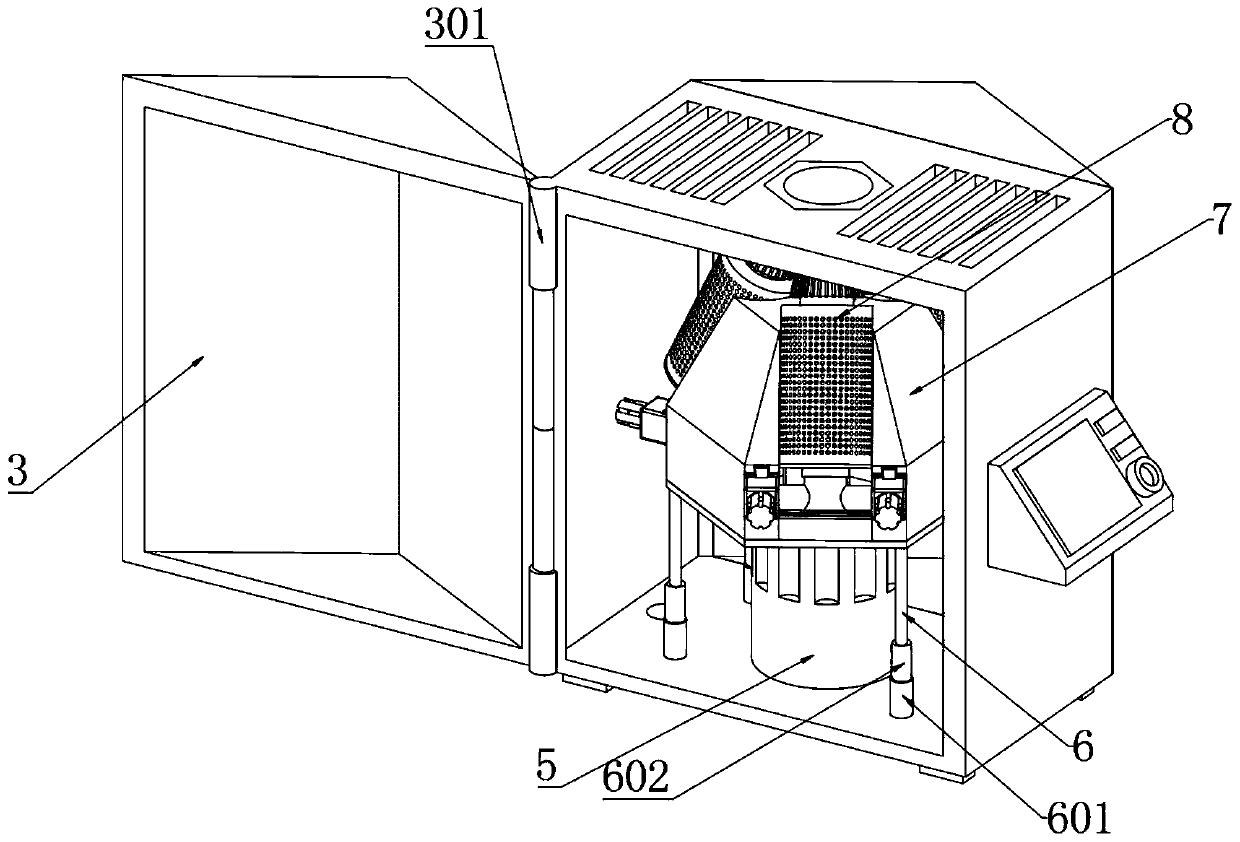

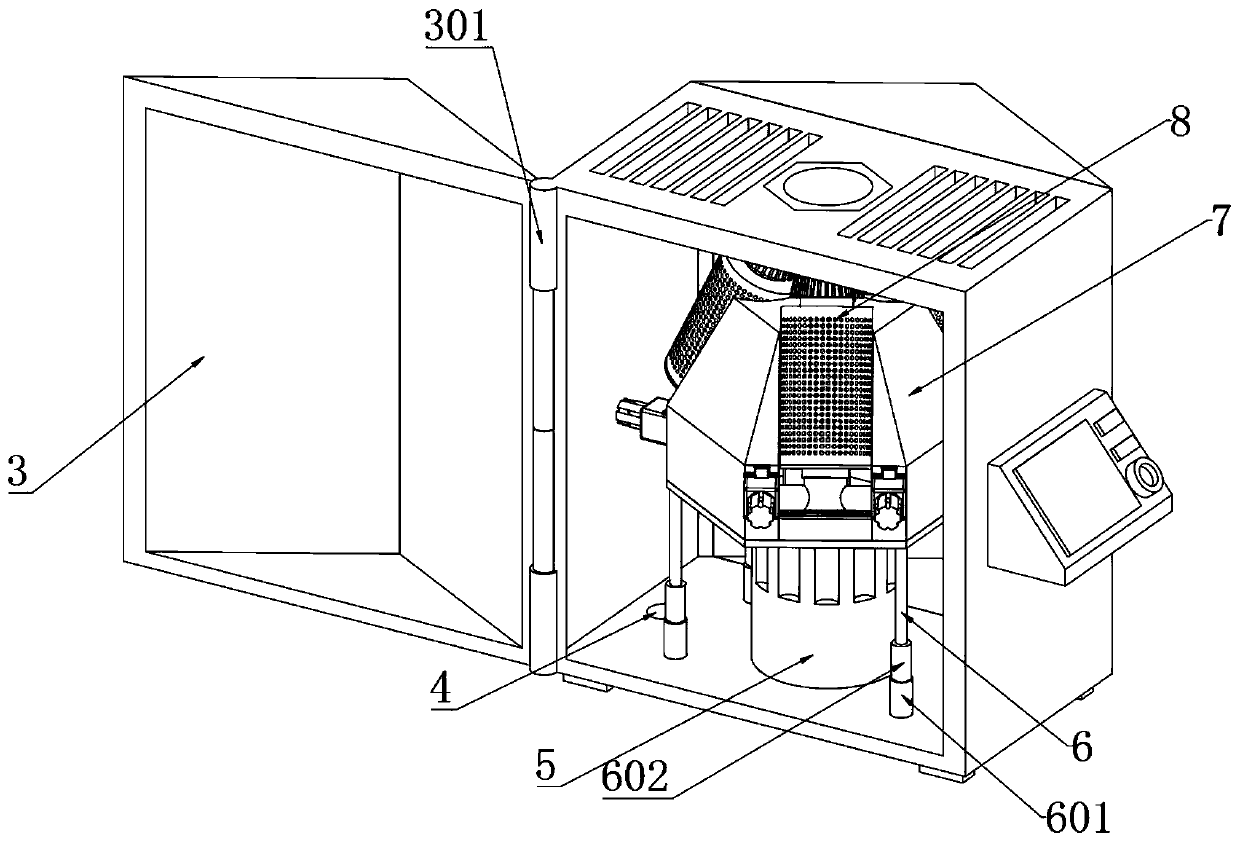

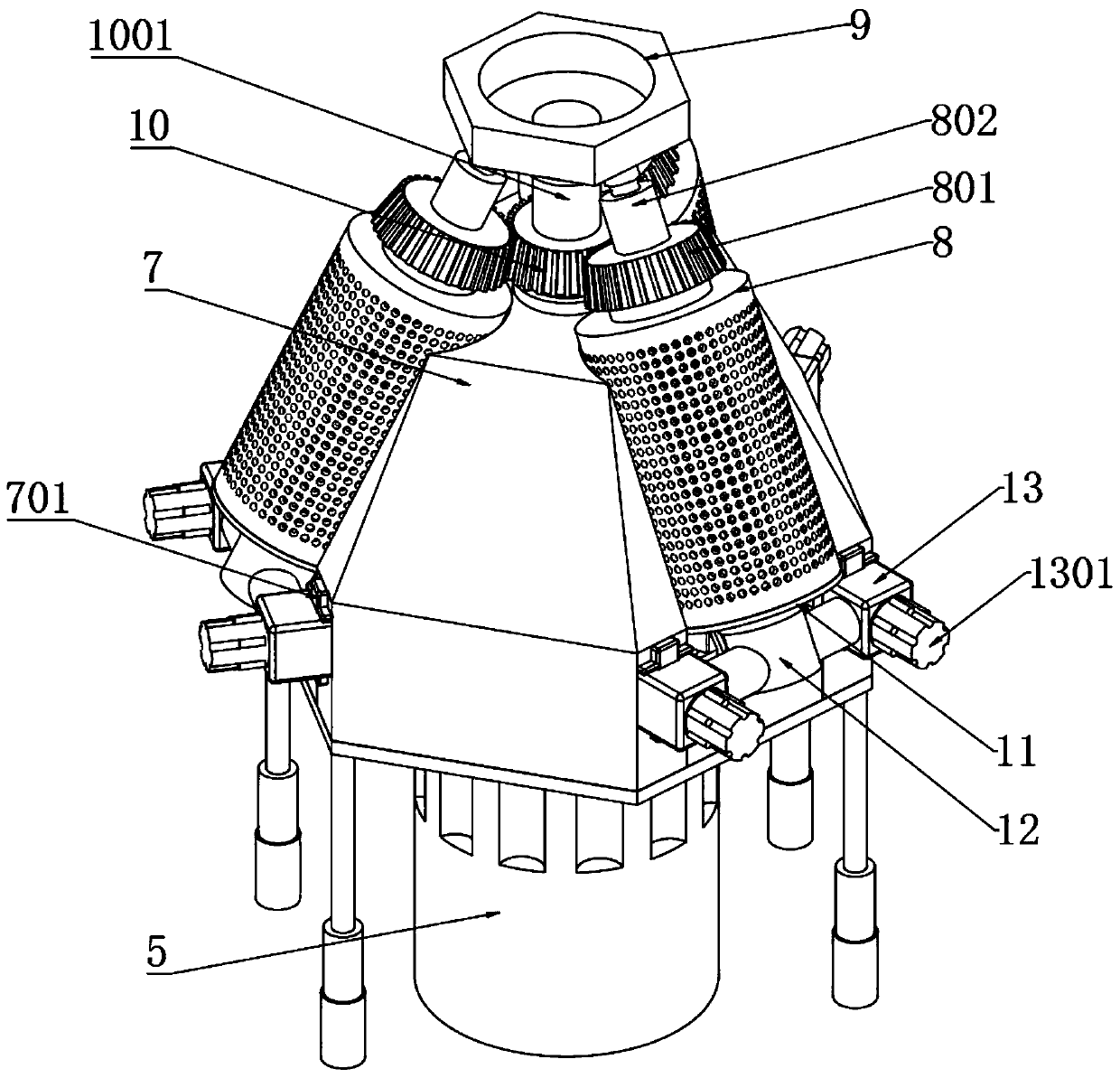

[0034] as attached figure 1 to attach Figure 9 Shown:

[0035] The invention provides a non-heating rotary dehydration device, which includes a body 1, a control panel 2, a chamber door 3, a drain port 4, a servo motor 5, a supporting positioning column 6, a dehydration shell 7, a dehydration cylinder 8, a fixed plate 9, Main gear plate 10, bottom head 11, T-shaped body 12, fixed block 13, middle support plate 14, rotating shaft 15, ventilation hole 101, hinge 301, fixed sleeve 601, movable pin 602, positioning body 701, barrel groove 702 , fixed hole 703, driven gear plate 801, driven connecting column 802, driving bearing collar 901, driven bearing collar 902, driving connecting column 1001, storage tank 1101, solid column 1102, fixing bolt 1301, flat plate Paddle 1501, level paddle 1502 and limit block 70101, the control panel 2 is fixed on the left end side wall of the body 1, and the body 1 is a regular hexahedron structure; seven groups of ventilation holes 101 are le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com