Full-automatic cloth edge cutting device

A fully automatic, cloth technology, applied in the cutting of textile materials, marking of textile materials, textiles and papermaking, etc., can solve the problems of low cutting efficiency and poor cutting quality, achieve high cutting effect, reduce labor intensity, improve The effect of the work environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

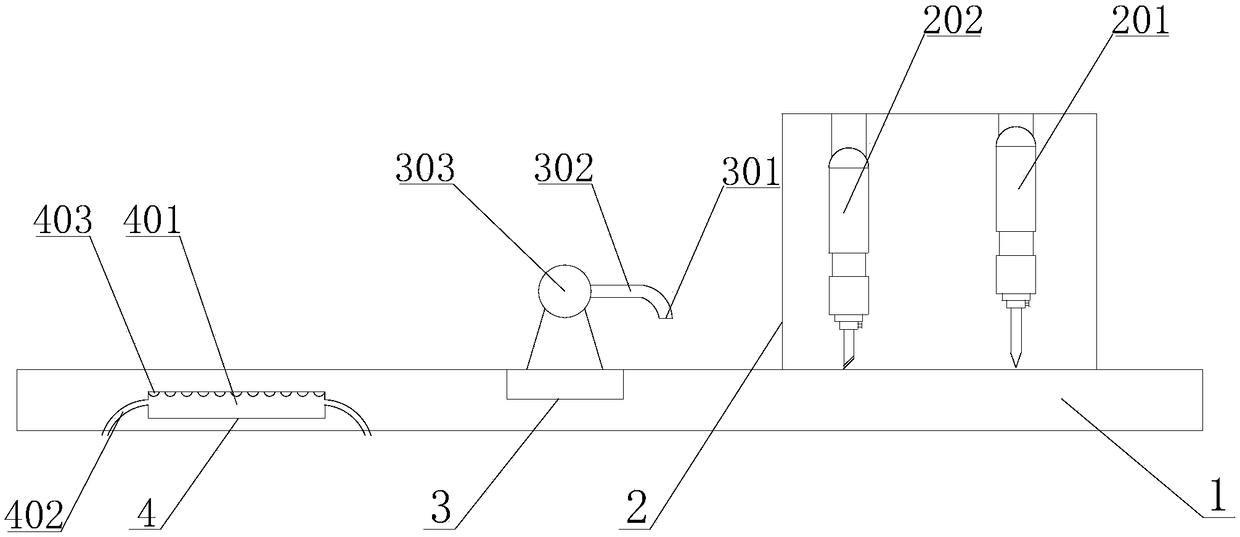

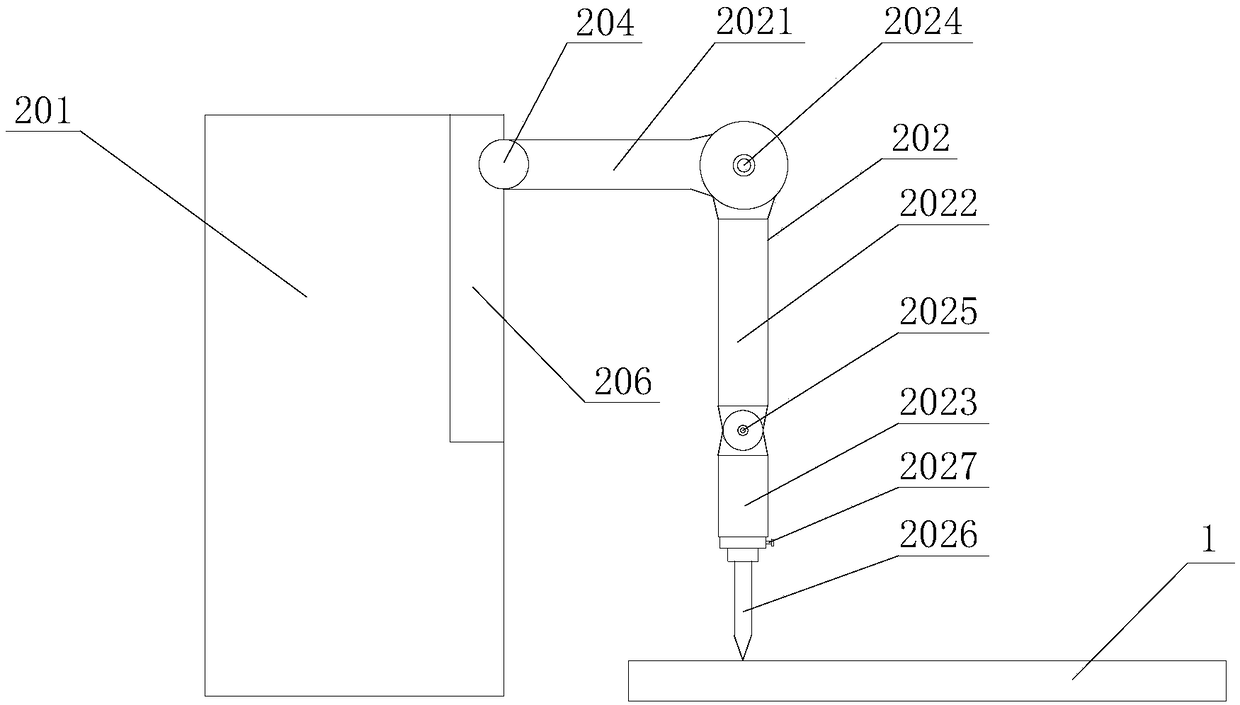

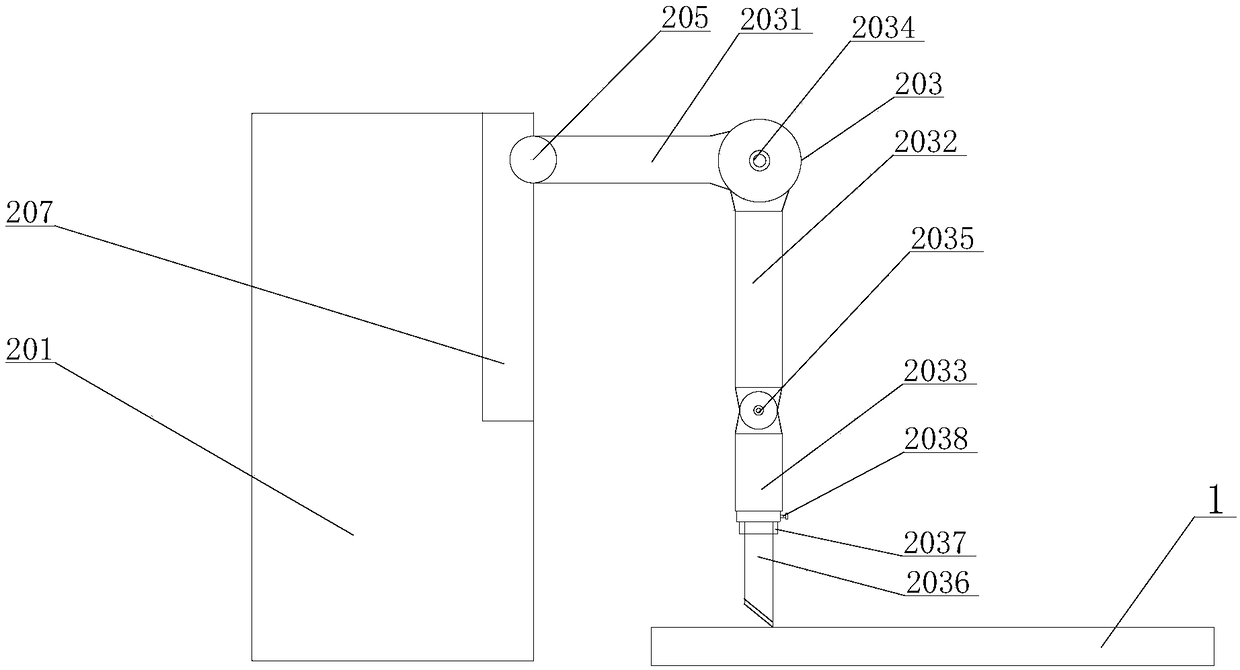

[0015] Such as figure 1 As shown, a fully automatic cloth edge trimming equipment includes a workbench 1, and the workbench 1 is successively provided with an edge trimming device 2, a dust suction device 3 and a heating device 4 from the cloth feeding end, and the edge trimming device 2 includes Control mechanism 201 and two manipulators, described manipulator one 202 and manipulator two 203 are connected with control mechanism 201 through roller one 204 and roller two 205 respectively, described control mechanism 201 is provided with track one 206 and track two 207, and described roller The first 204 and the second roller 205 move up and down on the first track 206 and the second track 207 respectively. The first manipulator 202 can be divided into an arm one 2021, an arm two 2022 and an arm three 2023. The arm one 2021 and the roller one 204 is connected, the other end of the first arm 2021 is connected with the second arm 2022 through the first rotating shaft 2024, the sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com