Laser spot welder for battery

A laser spot welding and battery technology, applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of low welding efficiency, achieve the effect of improving welding efficiency, solving low welding efficiency and improving welding accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

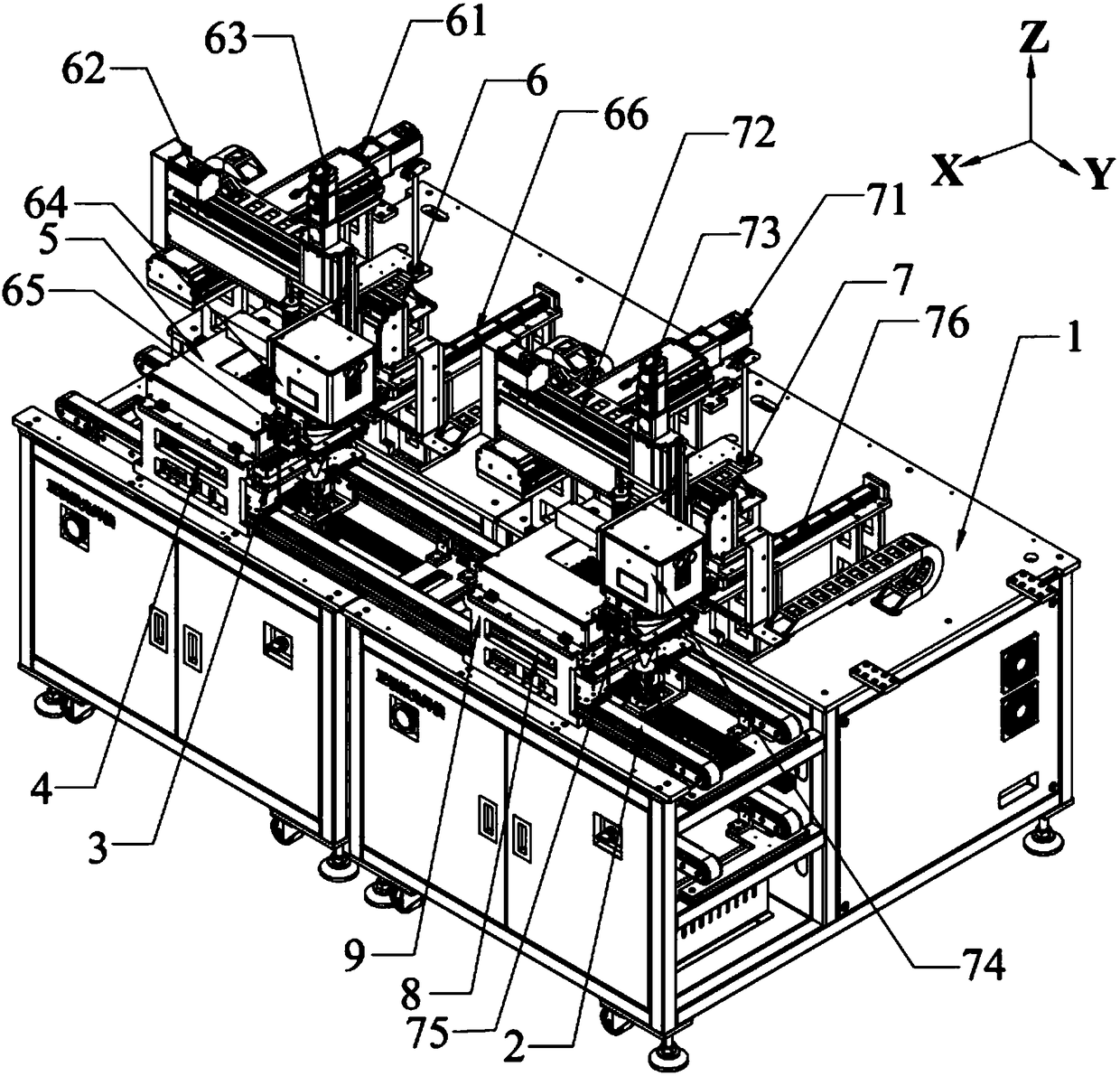

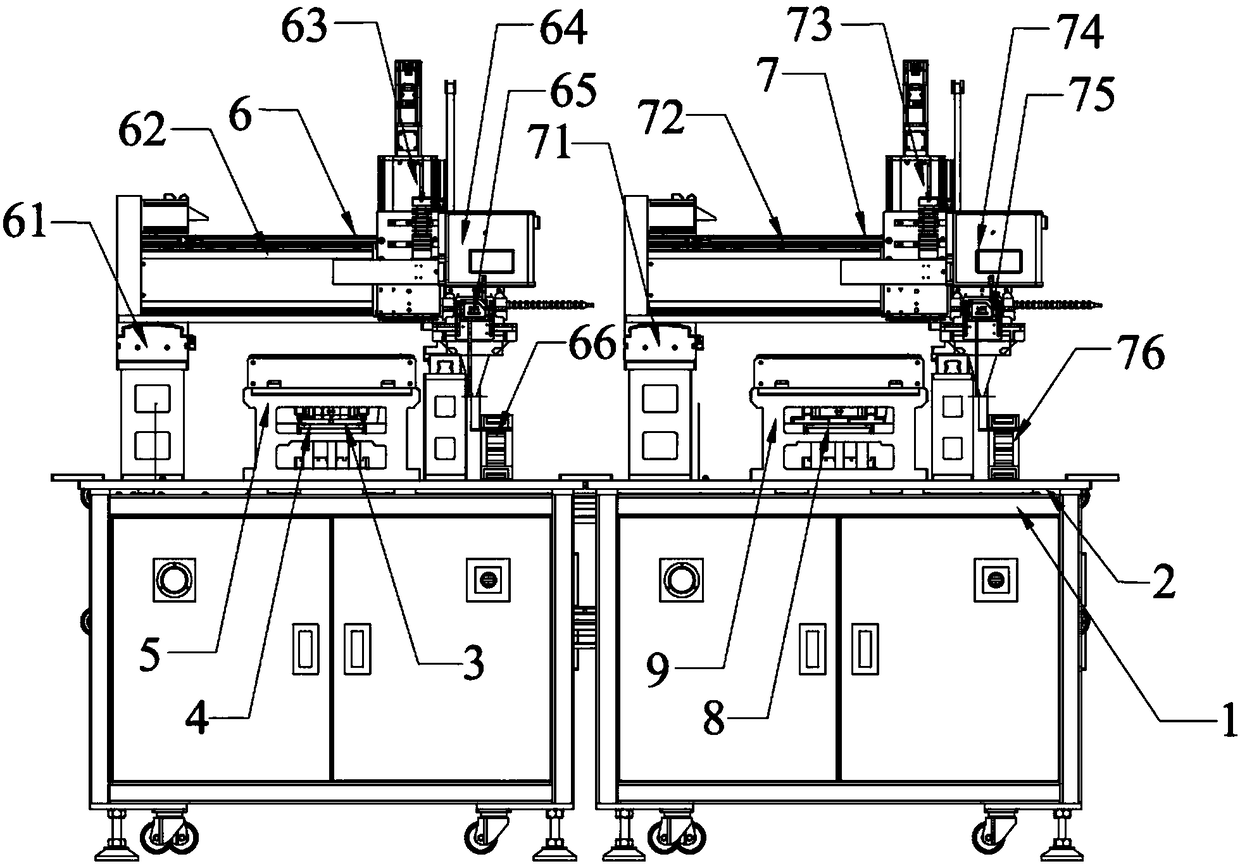

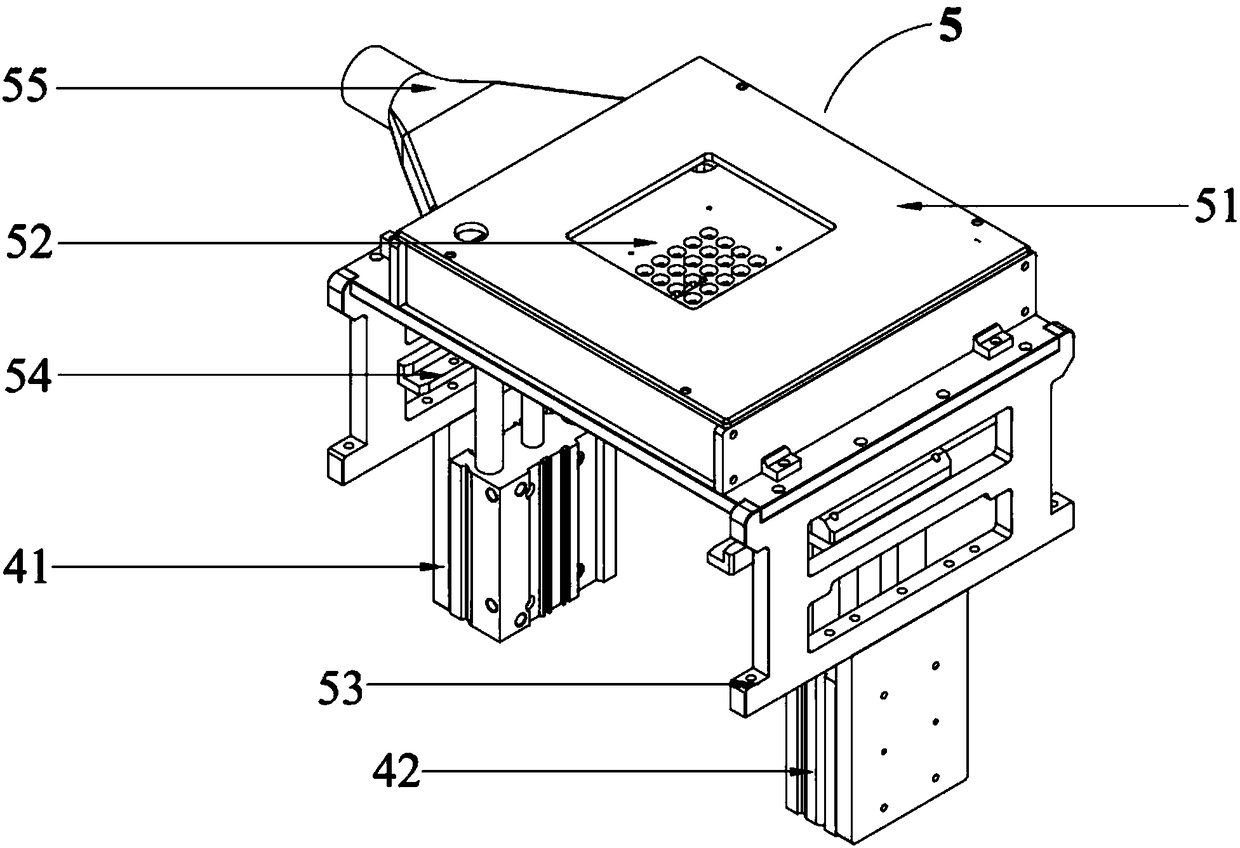

[0055] In this embodiment, the battery laser spot welding machine includes one welding station as an example. Please refer to figure 1 and 2 , respectively showing the three-dimensional structure diagram and the front view structure diagram of the battery laser spot welding machine. The structure of the battery laser spot welding machine provided by the present embodiment includes: a frame 1, a transmission line 2, a plurality of carriers 3 and the first welding station; the first welding station includes: the first spot welding mechanism 6 and The first stop piece.

[0056]The transmission line 2 is set on the frame 1, the transmission line 2 has a conveying line and a return line, the conveying line is used to transport the carrier 3 on which the battery module is to be welded, and the return line is used to recover the empty carrier; the carrier 3 There are a plurality of them, which are arranged at equal intervals on the transmission line 2. Specifically, the carrier 3 ...

Embodiment 2

[0063] This embodiment provides a battery laser spot welding machine with another structure. The battery laser spot welding machine in this embodiment is different from Embodiment 1 in that it includes two welding stations, which are the first welding station and the second welding station, and the two welding stations are arranged on the transmission line 2 according to the process. on the same side. Of course, the two welding stations can also be located on opposite sides of the transmission line 2 .

[0064] review figure 1 and 2 , The second welding station includes: the second spot welding mechanism 7, the second stopper, the second jacking assembly 8 and the second positioning mechanism 9 with the same function as the first embodiment. The second spot welding mechanism 7 , the second stopper, the second jacking assembly 8 and the second positioning mechanism 9 adopt the same operation principle as that of the first embodiment to realize positive electrode welding of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com