Tubular strander screw strand collecting and arranging device for rare earth zinc steel strand

A technology of steel strand and tube stranding machine, which is applied in the field of tube strander screw receiving and arranging devices, which can solve problems such as defects in the appearance and quality of steel strands, pause or slippage of the cable arrangement, and high strength of steel strands, and achieve the appearance Improved packaging quality, fast wire take-up speed, and neat wire arrangement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with specific embodiments.

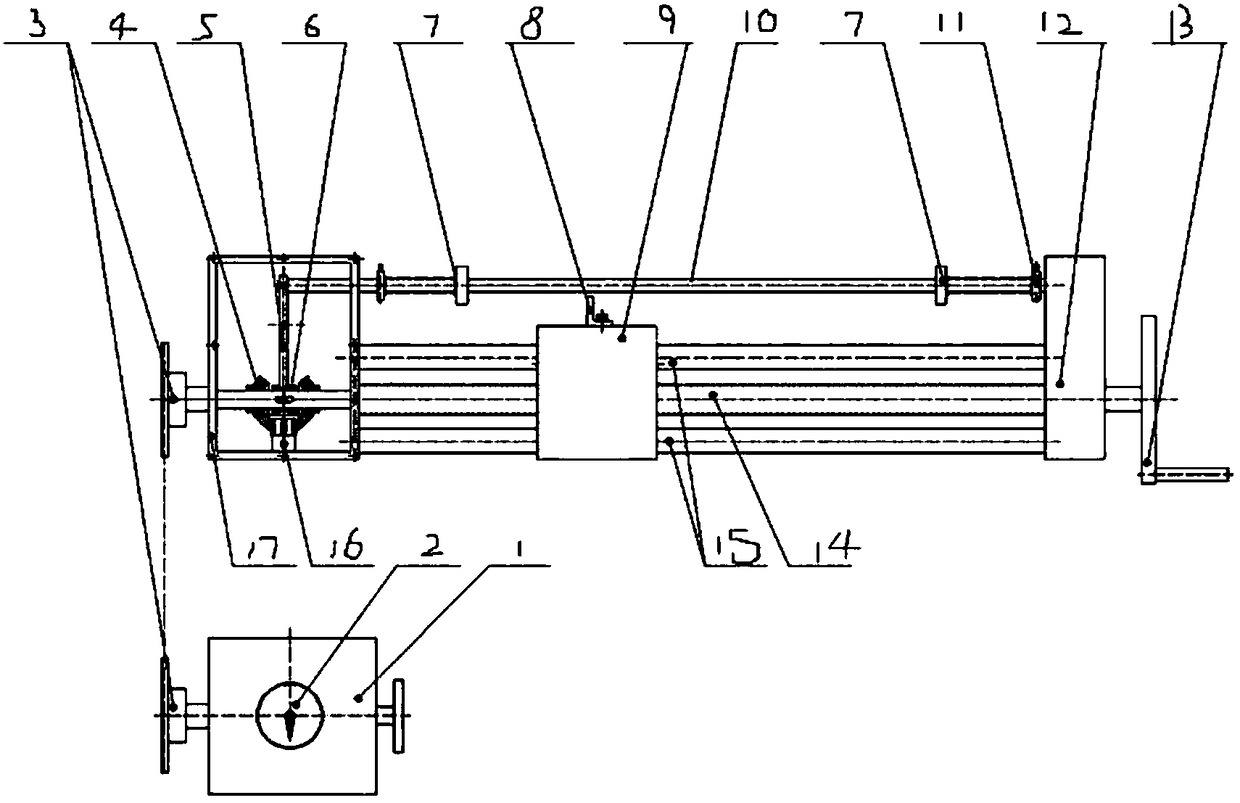

[0017] The embodiment of the present invention provides a pipe twister screw take-up and discharge device for rare earth zinc steel strands, such as figure 1 shown, including:

[0018] Including: sprocket 3, gearbox 1, transmission box 17, screw rod 14, polished rod 15, cable seat 9, control pole 10, frame 12, hand wheel 13.

[0019] The sprocket of the tube winch is connected to the input shaft of the gearbox 1, and the output shaft of the gearbox 1 is connected to the transmission case 17. The output shaft of transmission box 17 is connected with screw mandrel 14, and screw mandrel 14 is arranged on the frame 12, and is connected with handwheel 13, and the upper and lower sides of screw mandrel 14 are also respectively provided with polished rod 15...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com