Silicon crystal detection method and device

A detection method and detection device technology, which is applied in the direction of measuring devices, semiconductor/solid-state device testing/measurement, and material analysis, can solve the problems of increasing costs and energy consumption, and achieve the effect of quick learning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

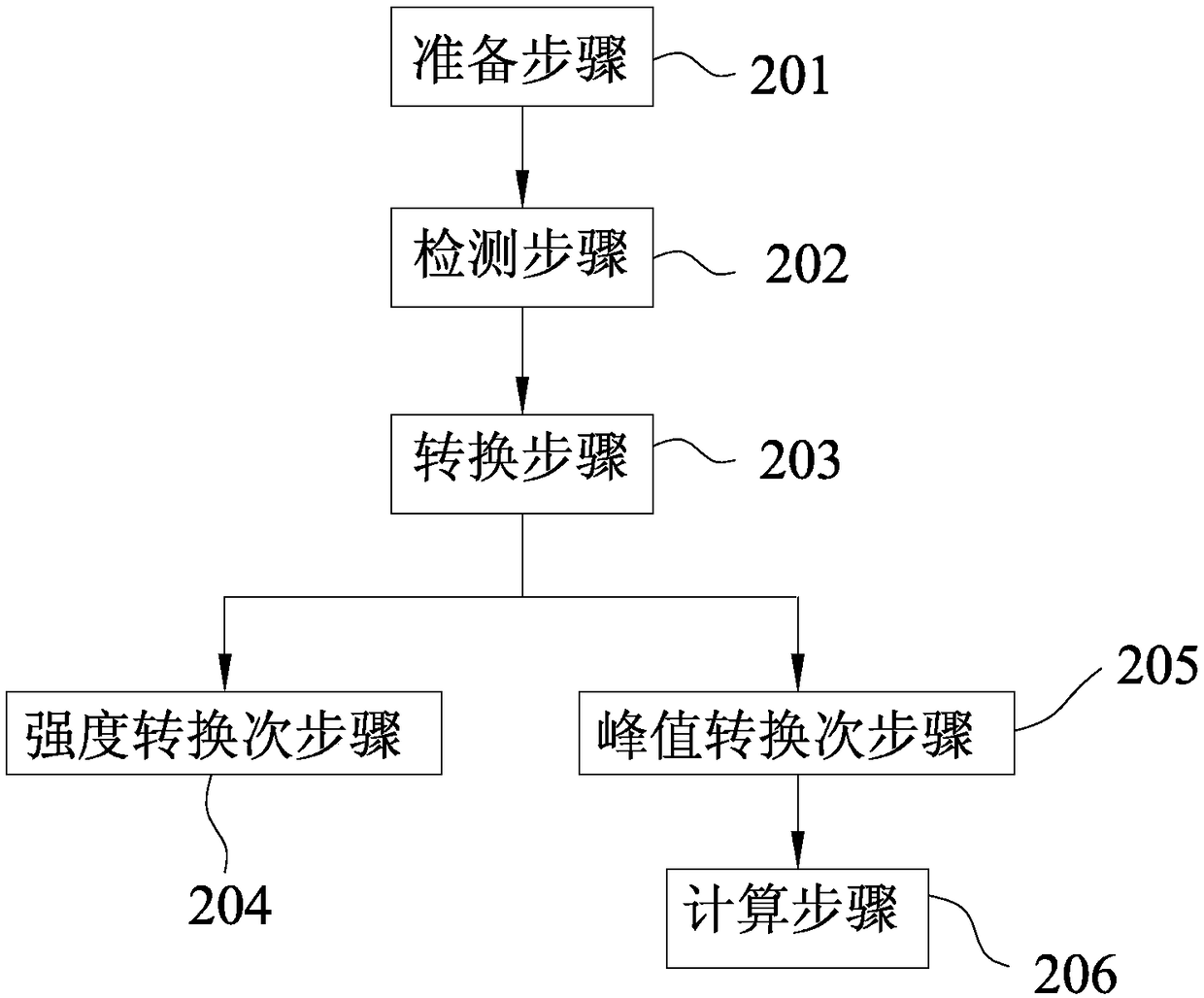

[0037] refer to figure 1 , a first embodiment of the detection method for silicon crystal material of the present invention includes a preparation step 201 , a detection step 202 , a conversion step 203 , and a calculation step 206 .

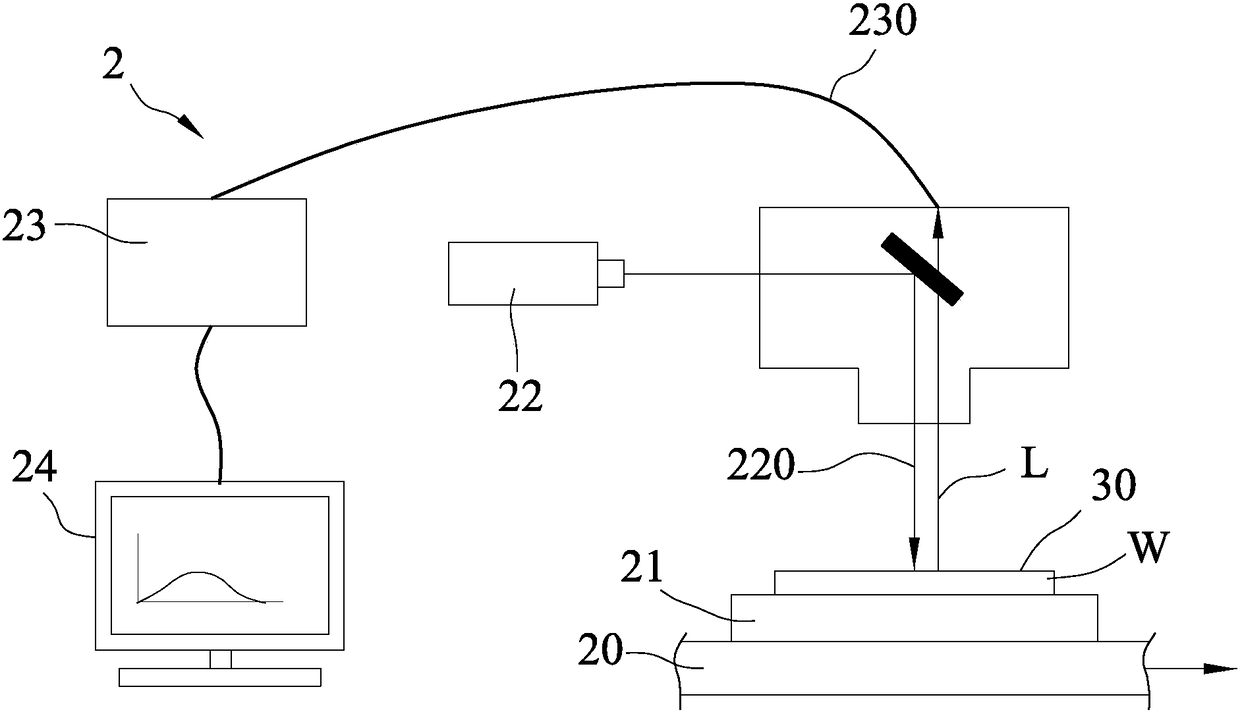

[0038] Cooperate with reference figure 2 , first perform the preparation step 201 , prepare a detection device 2 , and set a silicon crystal material to be detected on the detection device 2 .

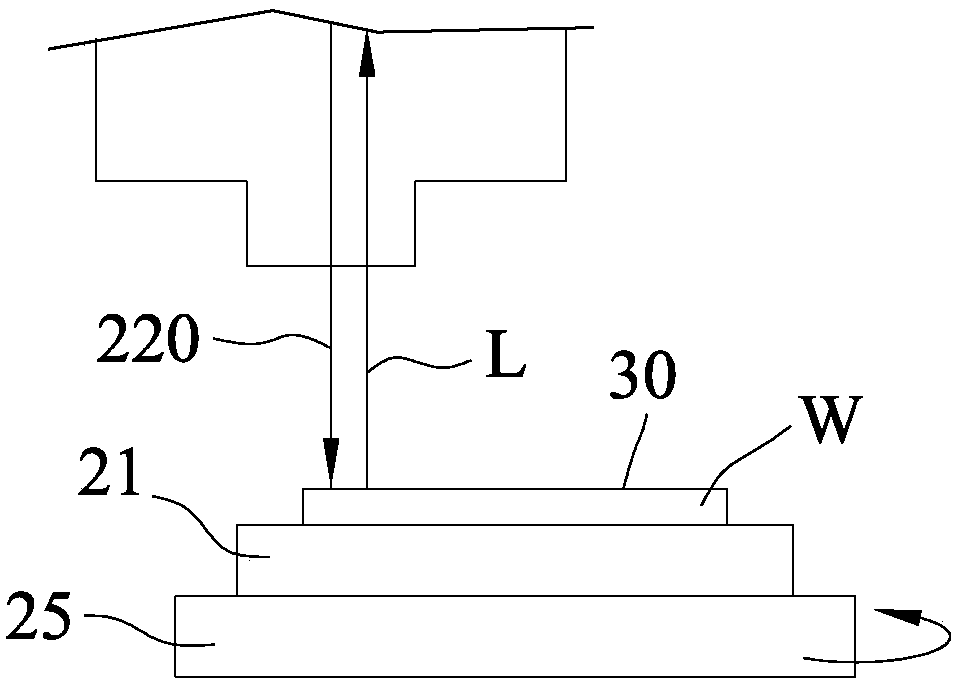

[0039] Specifically, the detection device 2 includes a stage 21 arranged on a slide rail 20 and capable of moving along a predetermined path of the silicon crystal material, a laser 22 capable of emitting a laser light source 220, a light receiving The light receiver 23 of the component 230, and an operation display 24. Specifically, the silicon crystal material can be a polycrystalline silicon ingot, a single crystal silicon ingot, a polycrystalline wafer, or a single crystal wafer. In this embodiment, the silicon crystal material is a single crystal...

specific example 1

[0054] A specific example 1 of the silicon crystal material detection method of the present invention is the silicon crystal material detection method of the first embodiment, and the intensity conversion sub-step 204 to the conversion step 203 is performed.

[0055] Cooperate with reference figure 1 and figure 2 , a single crystal wafer W 1 (not shown in the figure) is arranged on the stage 21, and uses a laser light source 220 with a wavelength of 808nm and a wattage of 1W close to the energy gap (band gap) of silicon to radially (for example, a single crystal wafer) diagonal, but not limited thereto, in other embodiments it can also be half of the diagonal) a single point multiple times to irradiate the single crystal wafer W 1 on the surface of the surface, making it produce multiple photoluminescence L. Next, use a spectrometer as the light receiver 23 to receive the photoluminescent light L, and generate a plurality of photoluminescent signals corresponding to the ph...

specific example 2

[0057] The implementation conditions of a specific example 2 of the silicon crystal material detection method of the present invention are substantially the same as the specific example 1, the difference is that the specific example 2 is to detect another single crystal wafer different from the specific example 1 W 2 (not shown).

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com