Automatic control method for water content of sintering mixture

A technology for sintering mixtures and sintering mixtures, which is used in special data processing applications, instruments, electrical digital data processing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

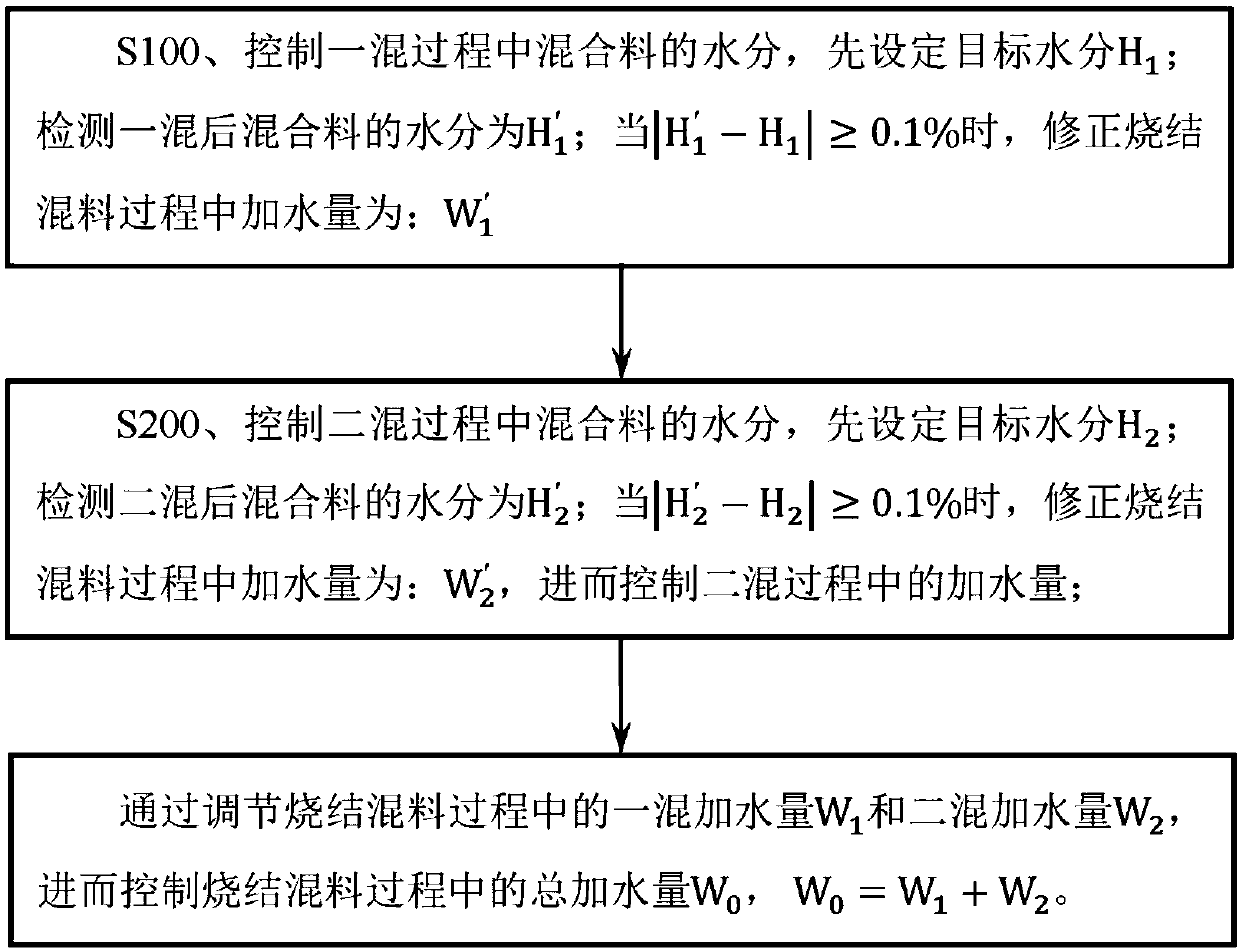

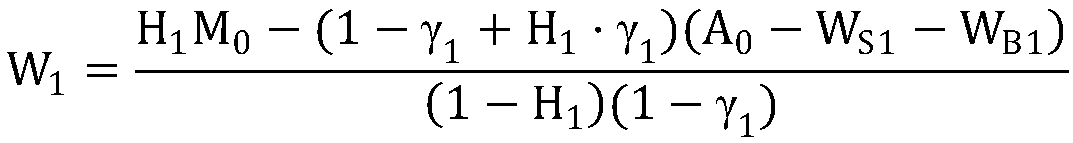

Method used

Image

Examples

Embodiment 1

[0081] The raw materials used for sintering include iron-containing raw materials, flux and fuel. These raw materials all contain a certain amount of original moisture, but the moisture value cannot meet the requirements of sintering. Add moisture when mixing and secondary mixing. The main purpose of primary mixing is to add water to moisten and mix evenly, so that the water content, particle size and components in the material can be evenly distributed, while the secondary mixing should not only continue to mix, but also carry out supplementary wetting. The main purpose is to granulate .

[0082] The sintered material contains crystallization water and physical water, the former mainly comes from the ore itself, and the latter comes from the externally added water of the material. Adding water to the powdery sintering material is mainly to help the mixture into balls and granules, and to improve the air permeability of the material layer; secondly, during the sintering proce...

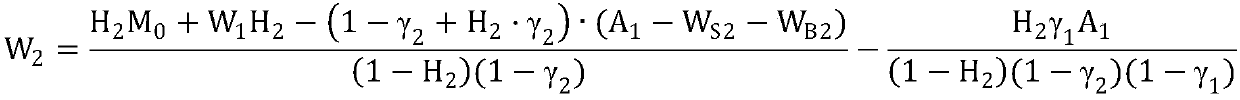

Embodiment 2

[0114] Using the amount of water calculated in Example 1, by setting the amount of water added in the first mixing and second mixing, the final moisture of the sintering machine is further estimated, and the final moisture is H 3

[0115]

[0116] A 2 : Water content of the mixture after first mixing, A 2 =(1-γ 2 )*(A 1 +W 2 -W S2 -W B2 );

[0117] gamma 3 : Water evaporation rate of the secondary mixture, γ 3 The value of is 1~5%, and the present embodiment is 1%;

[0118] W S3 : water absorption of mixed quicklime, W S3 = m S ·α S3 ·β S 32.14%; where α S3 is the water absorption rate of quicklime, α S3 The value is 5-15%, and this implementation takes 10%; β S is the CaO content of quicklime, and the CaO content of the quicklime adopted this time is 78.88%, W S2 =0.91t / h;

[0119] W B3 : Water absorption of a mixed dolomite, W B3 = m B ·α B3 ·β B 32.14%; where α B3 is the water absorption rate of dolomite, α B3 Value is 5~8%, and the present embo...

Embodiment 3

[0122] The basic content of this embodiment is the same as that of Embodiment 1, except that the raw material ratio and moisture content of this embodiment are as shown in Table 2. (1-1) Water absorption α of quicklime when first mixed S1 Calculated by the following formula:

[0123]

[0124] K S1 : Coefficient of water absorption of quicklime in a mixture, K S1 The value is 0.16~0.20; this embodiment takes 0.18

[0125] t 1 : Mixing time for one mixing, t 1 The range is 3~6min, and the present embodiment takes 5min

[0126] The percentage of quicklime particle size ≤ 3mm, The value is 92~95%, and the present embodiment is 92%;

[0127] h 1 : mix target moisture, the present embodiment gets 7.39%;

[0128] T 1 : temperature of a mixture, T 1 The range is between 40°C and 55°C, and 44°C is used in this embodiment;

[0129] m in this example s =40t / h, M 0 =798.50t / h;

[0130] Calculated to get α S1 = 54.99%;

[0131] Table 2 The cutting amount of each raw ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com