Plate trimming device

A technology of edge cutting and sheet metal, which is applied in the direction of shearing devices, knives for shearing machine devices, manufacturing tools, etc., can solve problems affecting the processing quality of sheet metal, equipment life, physical and mental health of workers, and low production efficiency, so as to ensure the quality of sheet metal The effect of processing quality and physical and mental health of workers, improving work efficiency and saving manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in further detail below by means of specific embodiments:

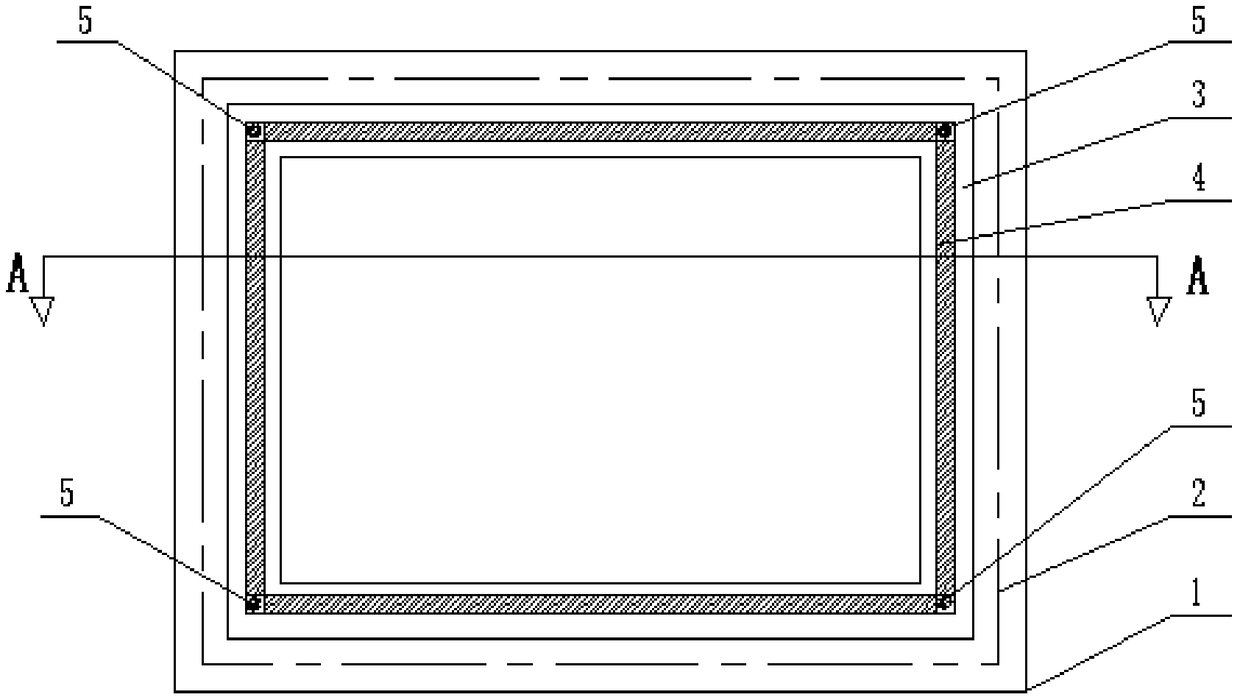

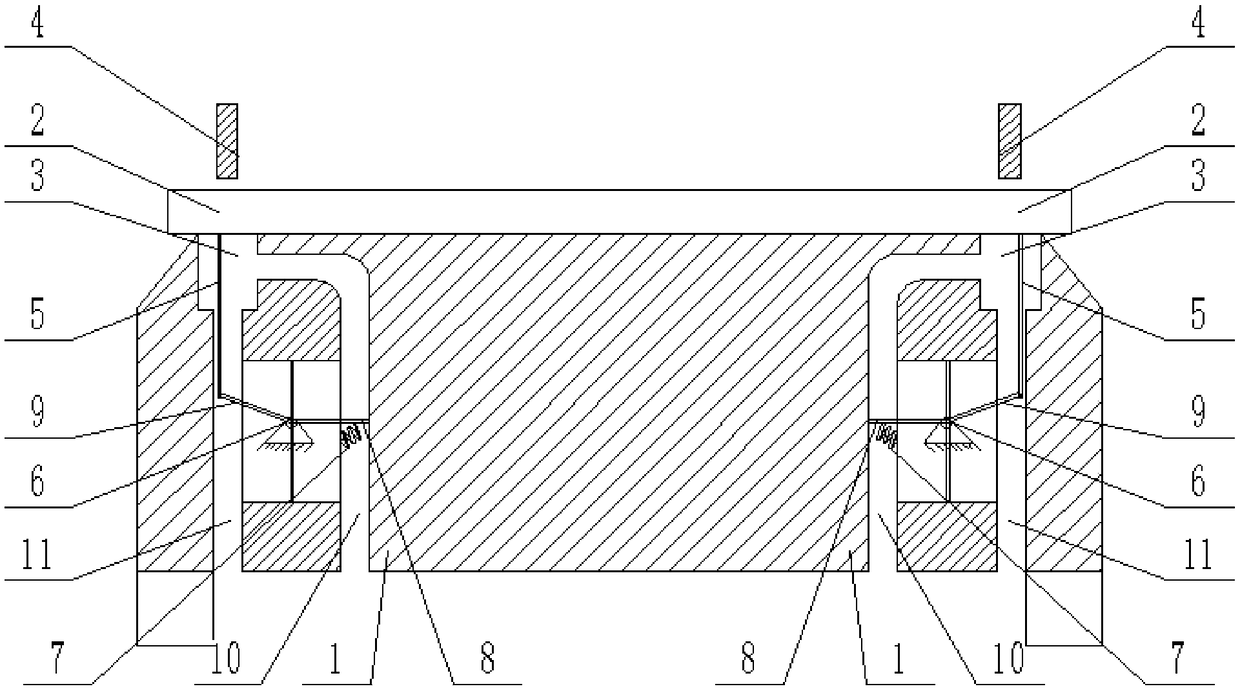

[0015] Instructions attached Figures 1 to 2 The reference signs in include: workbench 1, plate 2, groove 3, cutter 4, push rod 5, toggle switch 6, spring 7, driven plate 8, active plate 9, pipe 10, through hole 11.

[0016] Such as figure 1 As shown, the plate edge trimming device includes a workbench 1, a knife rest and a frame. The workbench 1 is located directly below the knife rest. The knife rest is a cuboid structure. The pulley and the knife rest are slidingly connected on the frame, and the four sides at the bottom of the knife rest are equipped with a cutter 4, the cutter 4 has an inclined cutting edge, and the knife rest is provided with a driving mechanism for driving the cutter 4 to move up and down. Such as figure 2 As shown, the workbench 1 is provided with a groove 3 for inserting the cutter 4, and the bottom of the groove 3 is provided with a through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com