Workpiece cavity support processing tooling

A workpiece and inner cavity technology, which is applied in the field of workpiece inner cavity support processing tooling, can solve problems such as failure to meet customer requirements, scratches, and lower product yield, so as to expand the processing range of workpieces, meet workpiece processing needs, and improve product quality. The effect of yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

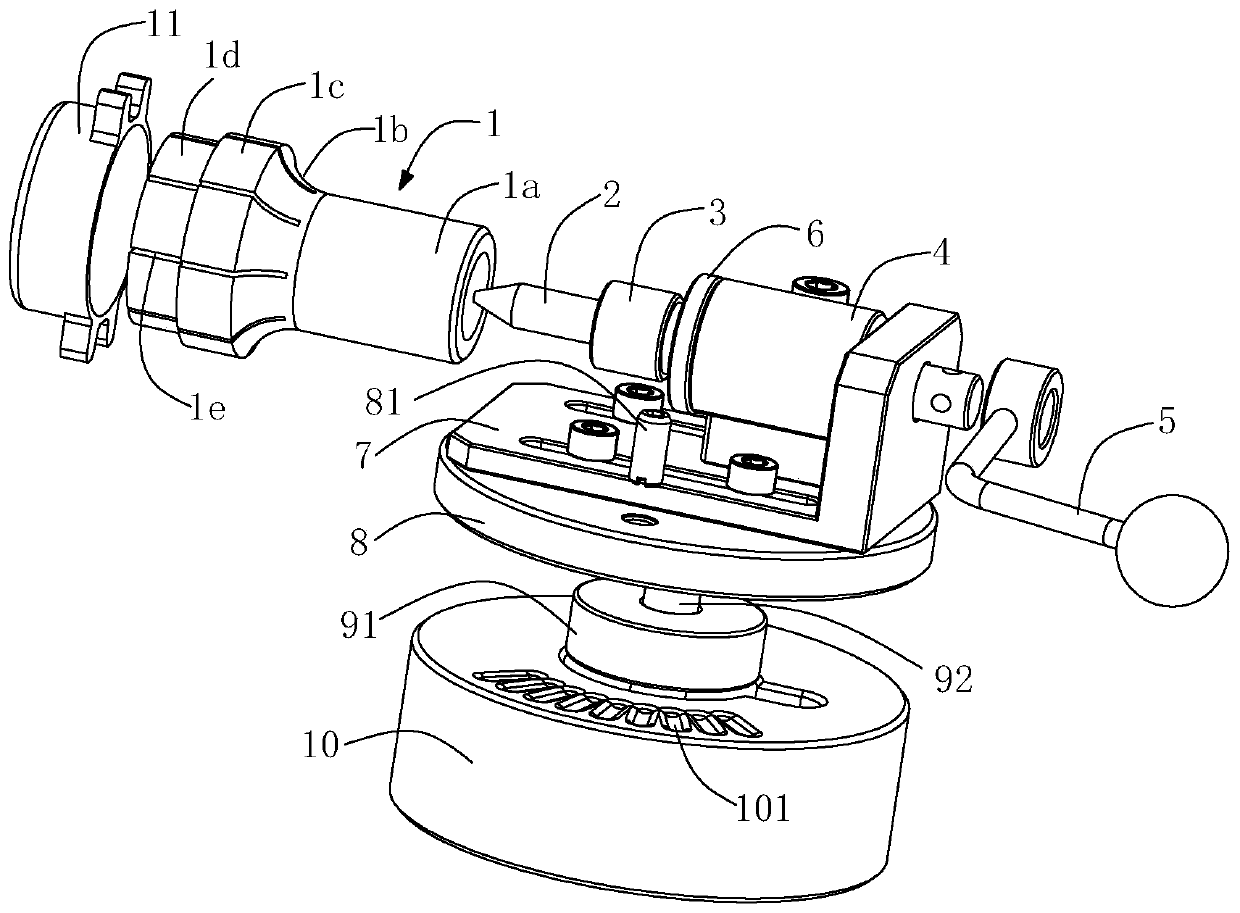

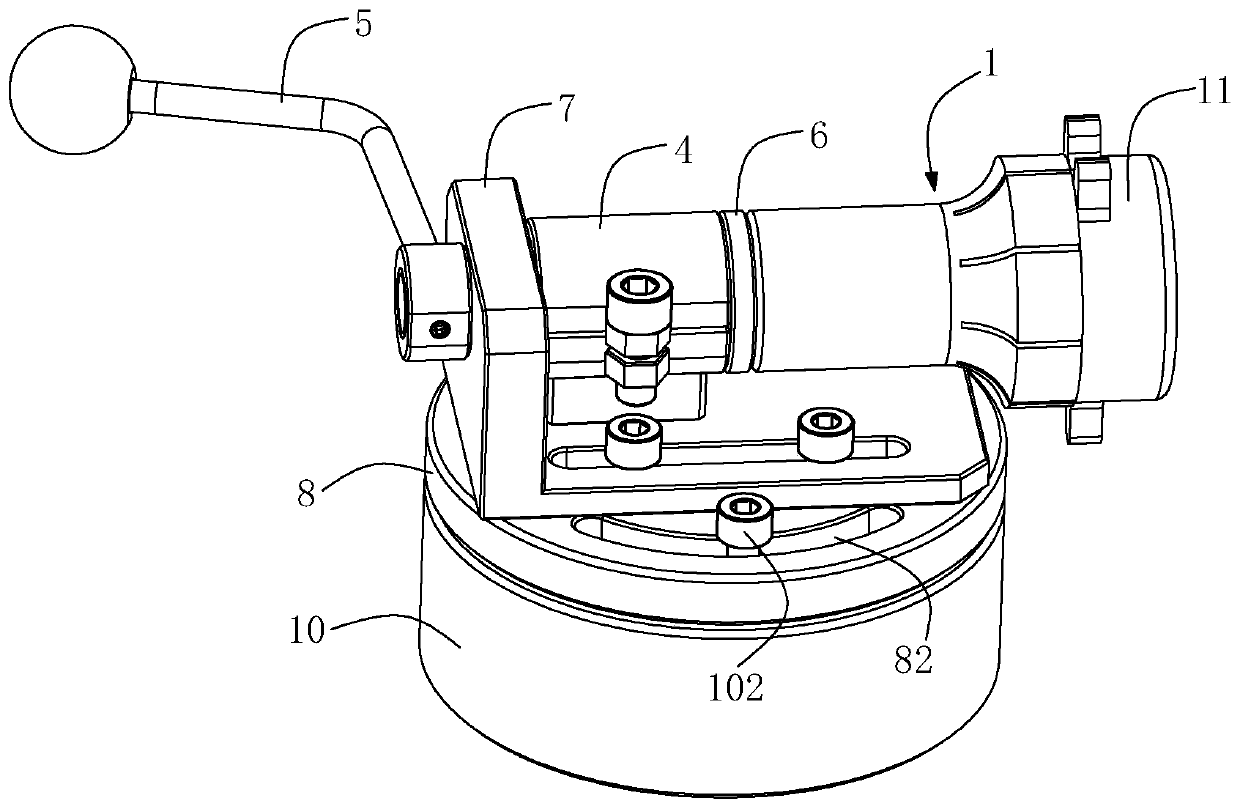

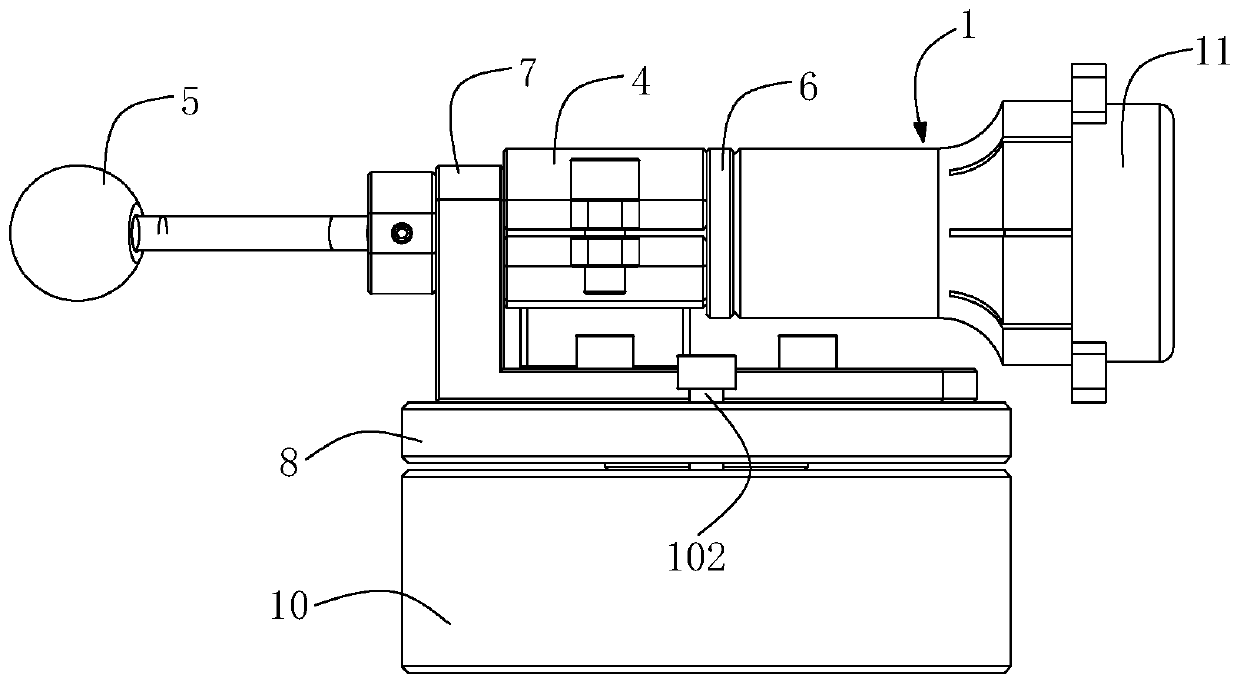

[0031] In the following, a further detailed and non-limiting description will be given of the workpiece inner cavity supporting processing tool of the present invention in conjunction with the accompanying drawings and embodiments.

[0032] For ease of description, the direction pointed by the tip of the ejector pin is defined as "front", and the direction opposite to "front" is defined as "rear".

[0033] The workpiece inner cavity supporting processing tool of the present invention includes a workpiece inner cavity supporting mechanism and a rotating mechanism.

[0034] Such as Figure 1 to Figure 5 Commonly shown, wherein, the workpiece inner cavity support mechanism includes a threaded sleeve 6, a push rod 2, and an expansion sleeve 1; the threaded sleeve 6 is fixedly arranged, and the threaded sleeve 6 is provided with internal threads; the push rod 2 is provided with external threads, and the top The rod 2 is threadedly connected with the threaded sleeve 6, and the fron...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com