Reverse pumping concrete device and construction method for basement

A technology for pumping concrete and pumping device, which is applied in the processing of building materials, construction, building structure, etc., can solve the problems of narrow construction site and inability to support pumping device, etc., to achieve rapid pouring operation and realize pouring operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to facilitate the understanding of the present invention, the following will be described in conjunction with the accompanying drawings and embodiments.

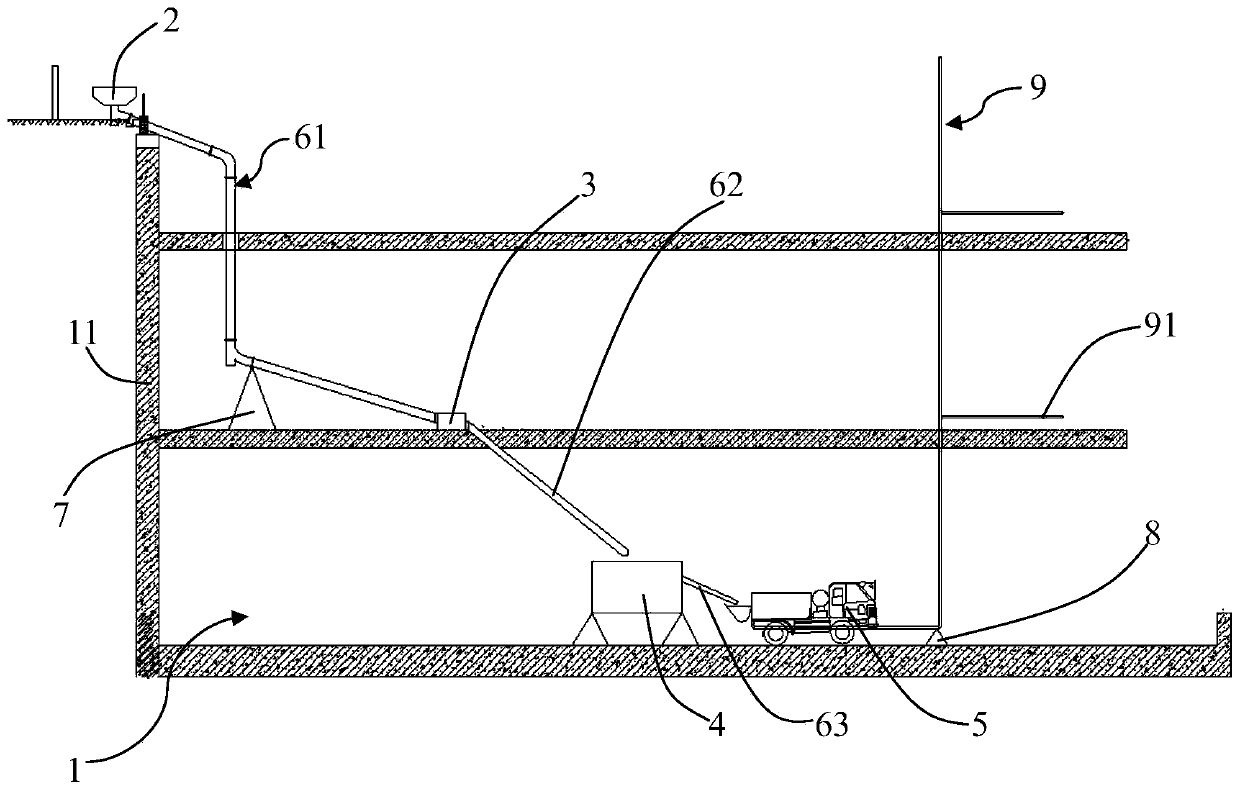

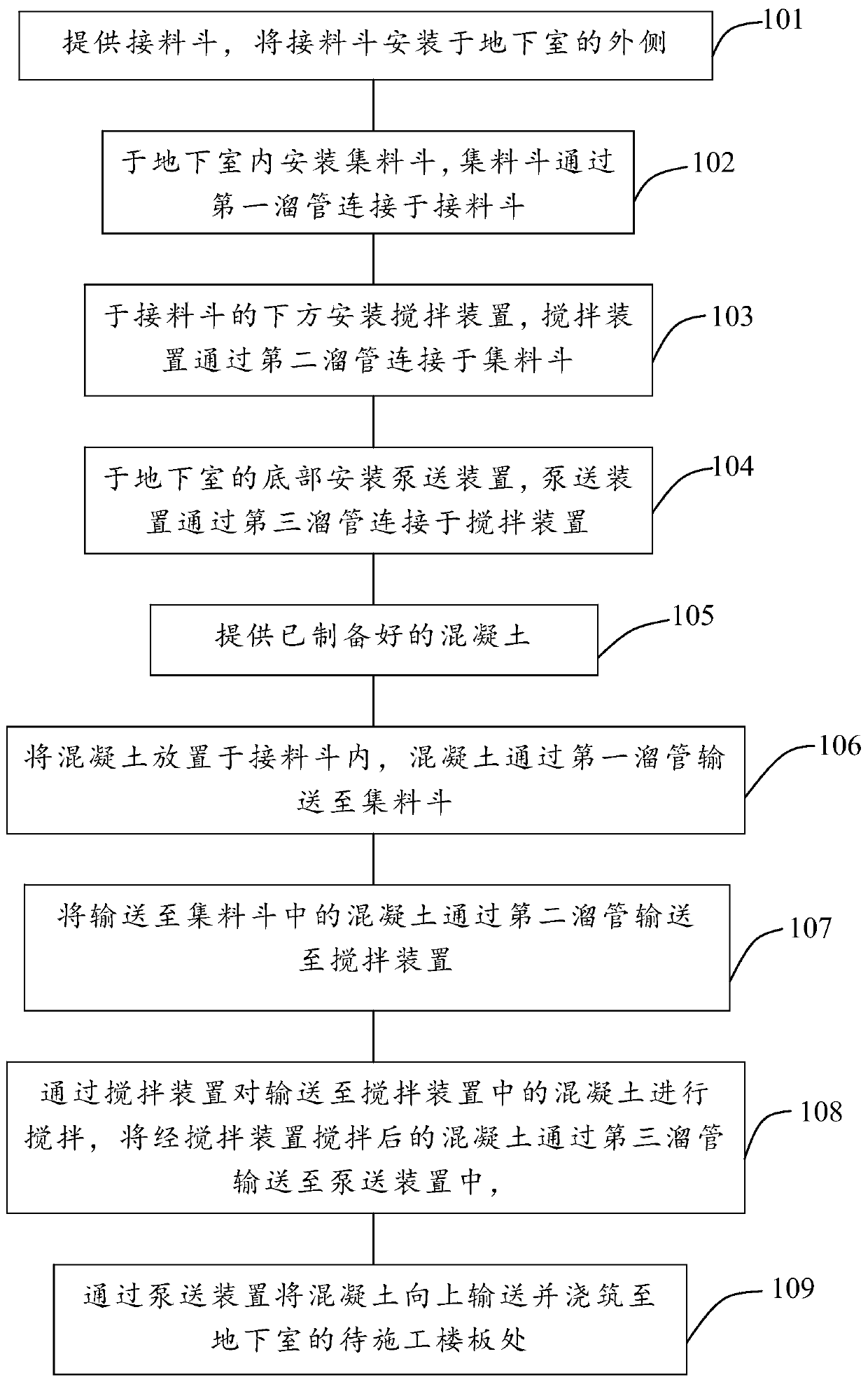

[0033] refer to figure 1 It can be seen that the present invention provides a reverse pumping concrete device for a basement, which includes a receiving hopper 2 arranged outside the basement 1 , a collecting hopper 3 arranged inside the basement 1 and a pumping device 5 . Wherein, the collecting hopper 3 is connected to the receiving hopper 2 through the first slide pipe 61, and the stirring device 4 is arranged under the collecting hopper 3, and the stirring device 4 is connected to the collecting hopper 3 through the second slide pipe 62; the pumping device 5 is installed in the basement 1, the pumping device 5 is connected to the stirring device 4 through the third slide pipe 63. In this embodiment, by installing the hopper 2 on the outside of the basement 1 (in actual use, the hopper 2 is installed on a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com