Turning washing device

A technology of inverting cleaning and cleaning box, which is applied to cleaning methods and utensils, cleaning methods using liquids, chemical instruments and methods, etc., can solve the problems of inability to realize the inversion cleaning of workpieces, inconvenient cleaning of workpieces, and insufficient cleaning. To achieve good adaptation value and promotion prospects, a wide range of use, and the effect of facilitating the operation of cleaning personnel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

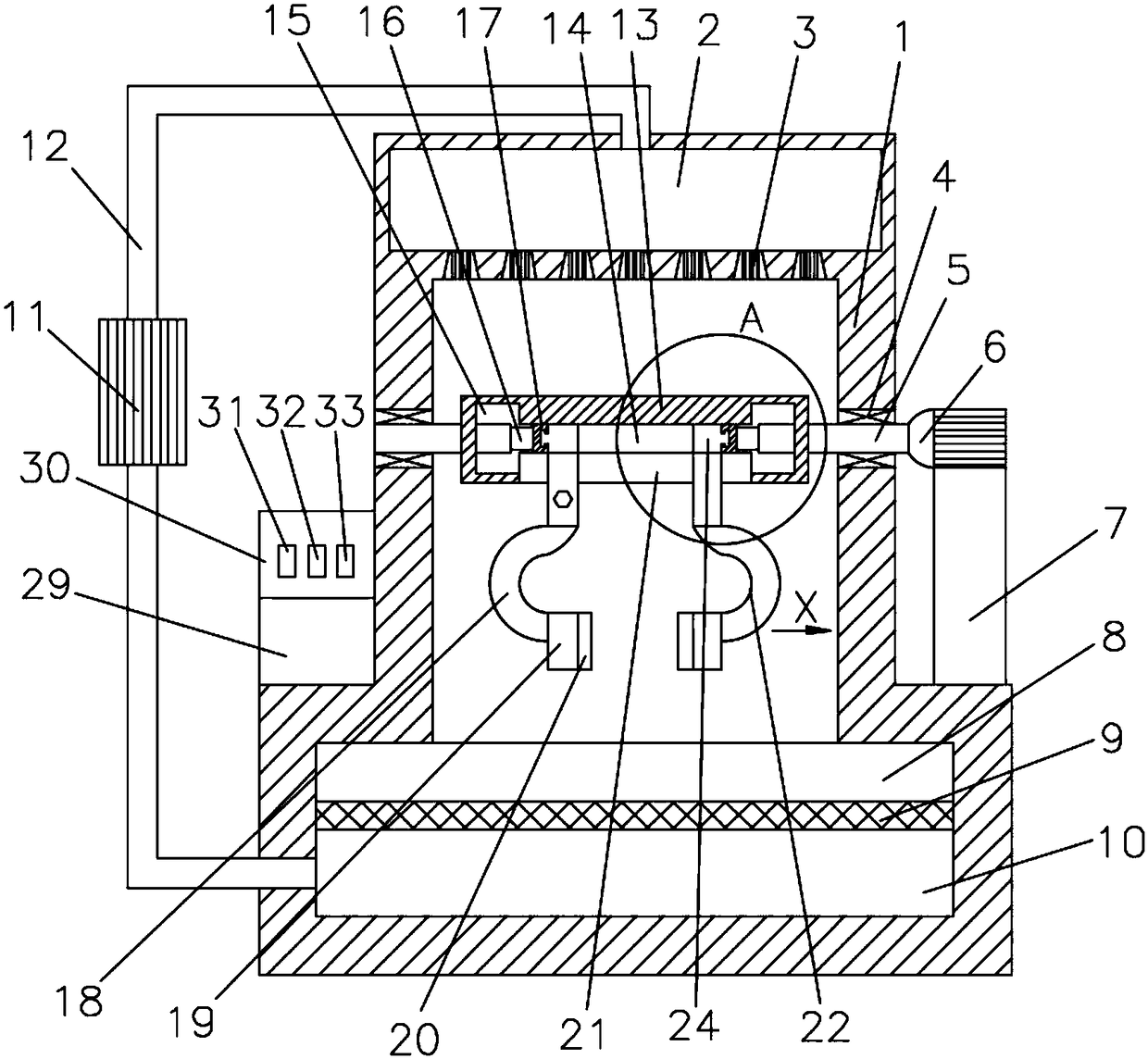

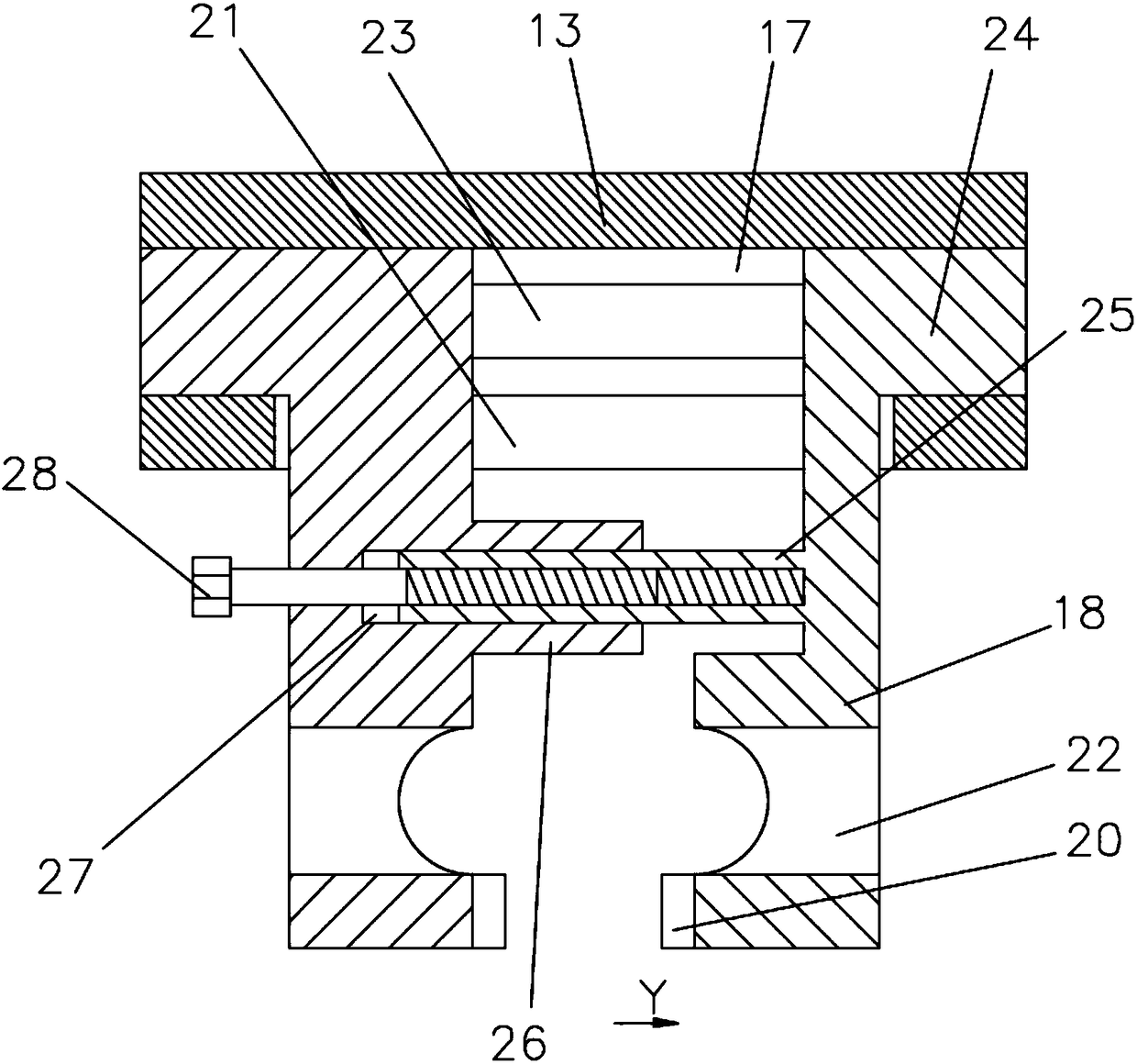

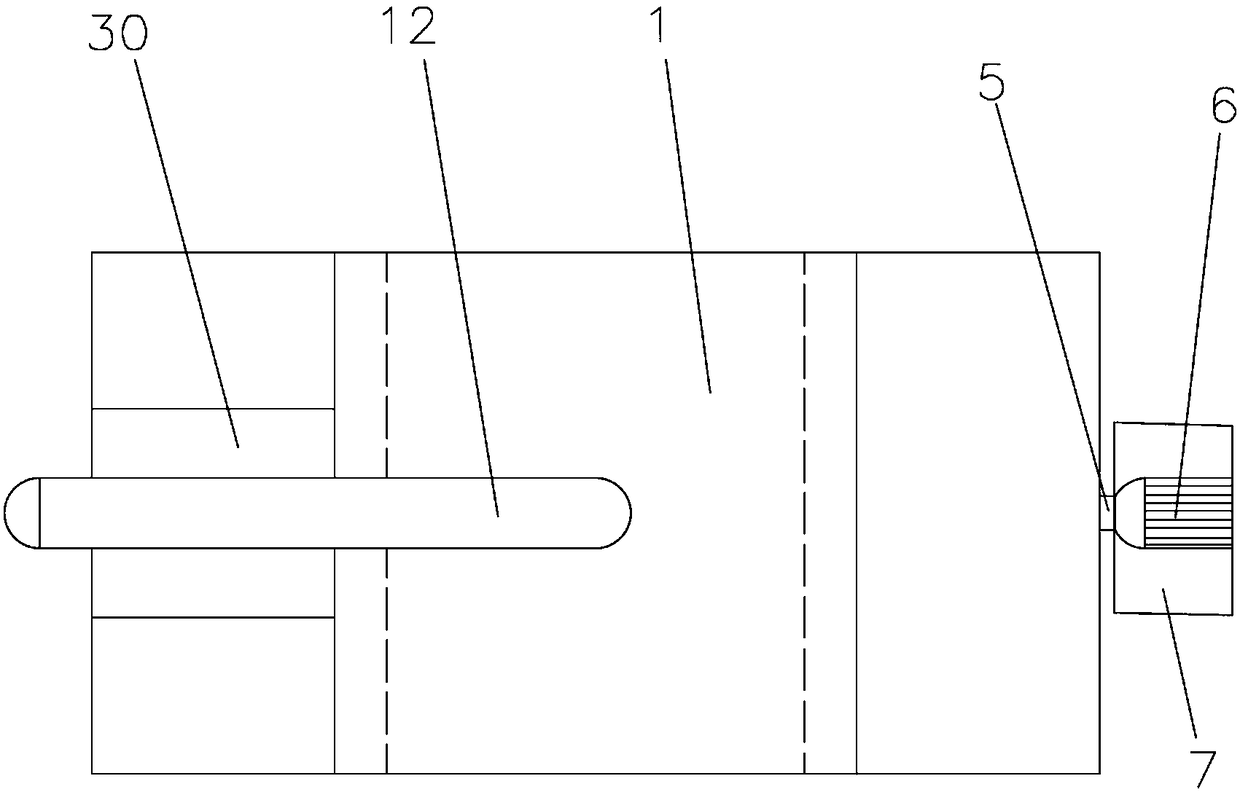

[0024] Example 1, such as Figure 1-4 Shown:

[0025]A kind of overturning cleaning device, comprising a cleaning box 1 with a square structure; the upper part of the cleaning box 1 is provided with a closed upper chamber 2 with a square structure, and the bottom of the inner wall of the upper chamber 2 is provided with a plurality of nozzles 3, and the interior of the nozzle 3 is provided with a plurality of Spray holes; the lower part of the upper chamber 2 is provided with a lower chamber, the front and rear of the lower chamber are through the cavity structure, and the left and right side walls of the lower chamber are rotatably installed with the installation shaft 5 through the bearing 4, and the installation shaft 5 is rotatable. The fixed connection is equipped with an overturning platform 13, and the two sides of the overturning platform 13 are symmetrically provided with a square installation groove 15, and a retractable hydraulic rod 16 is arranged in the installati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com