A Measuring Model for Ammunition Thermal Hazards Used in Full-Scale Fire Tests

A measurement model and full-scale technology, applied in the field of ammunition thermal disaster measurement model, can solve the problems of difficulty and danger, large measurement error, etc. contradictory effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

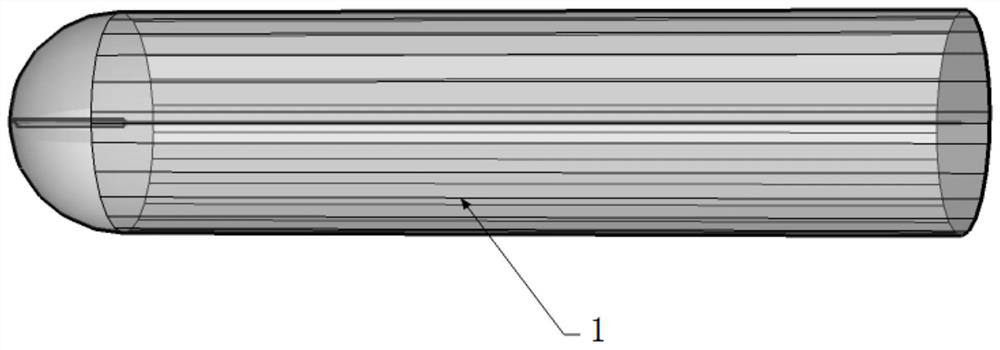

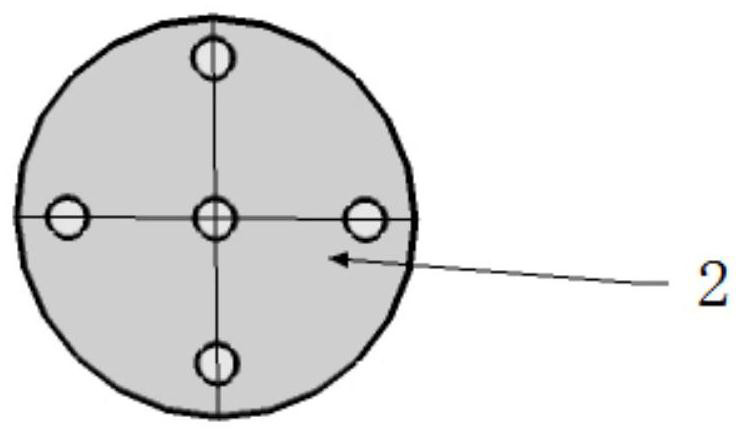

[0016] Such as figure 1 As shown, the ammunition thermal hazard measurement model for full-scale fire tests of the present invention includes a projectile 1 and different inert filling media arranged in the projectile 1, and the projectile 1 is designed according to the appearance characteristics of real ammunition The shell is full-sized, and the projectile body 1 is made of the same material as the ammunition. The different inert filling media replace the explosive and solid propellant filling inside the ammunition respectively; it also includes a fixed thermocouple patch and a high-precision Pt thermocouple wire, The fixed thermocouple patch and the high-precision Pt thermocouple wire are respectively installed on the surface of the body 1 and inside the body 1 using a thermocouple bracket 2, and the thermocouple bracket 2 is as follows: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com