Rail carrier

A carrier and rail technology, applied in transportation and packaging, conveyors, mechanical conveyors, etc., can solve the problems of waiting for robots, time-consuming model switching, and inability to meet the needs of automobile factories, and achieve safe and reliable operation, convenient operation, and convenient efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below:

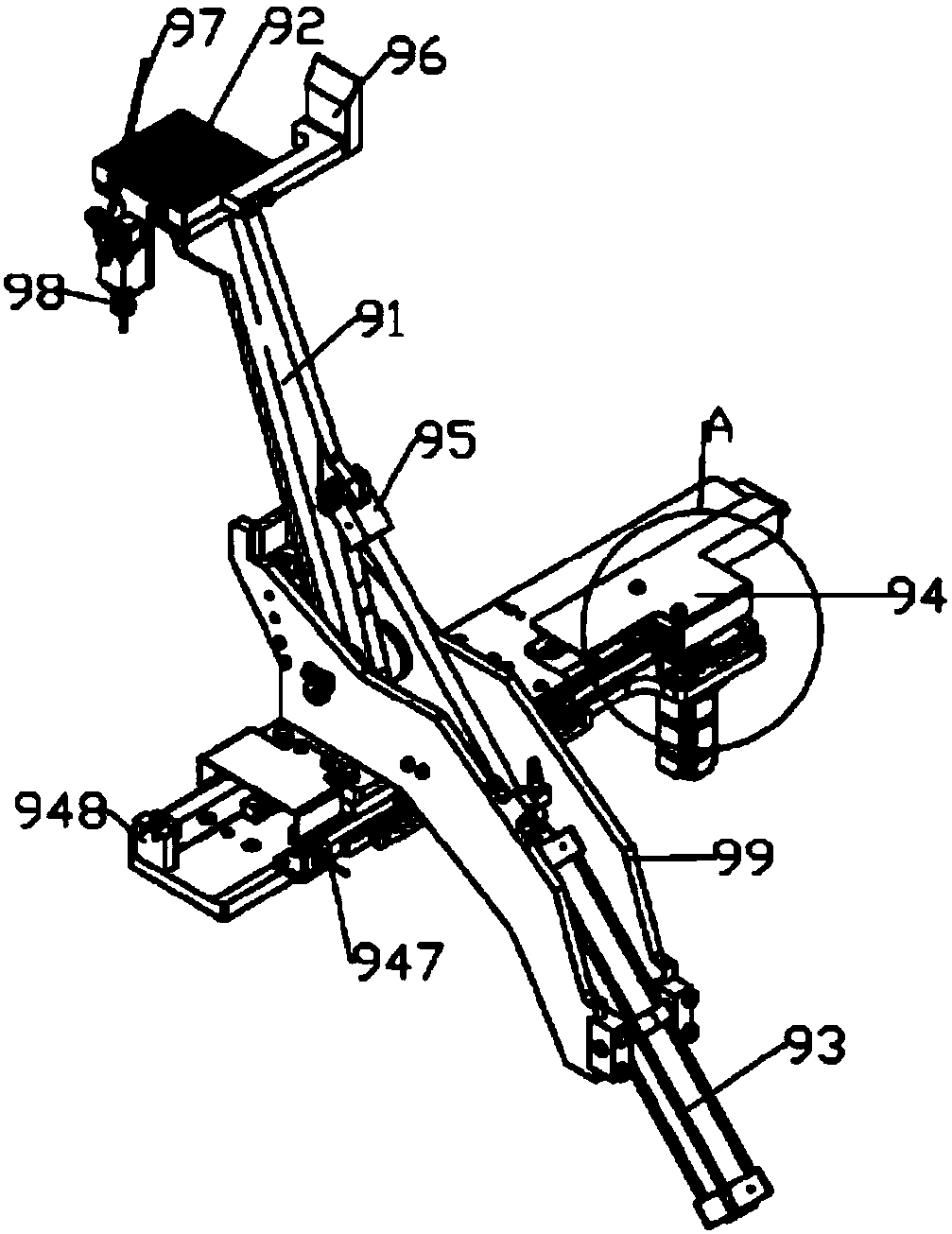

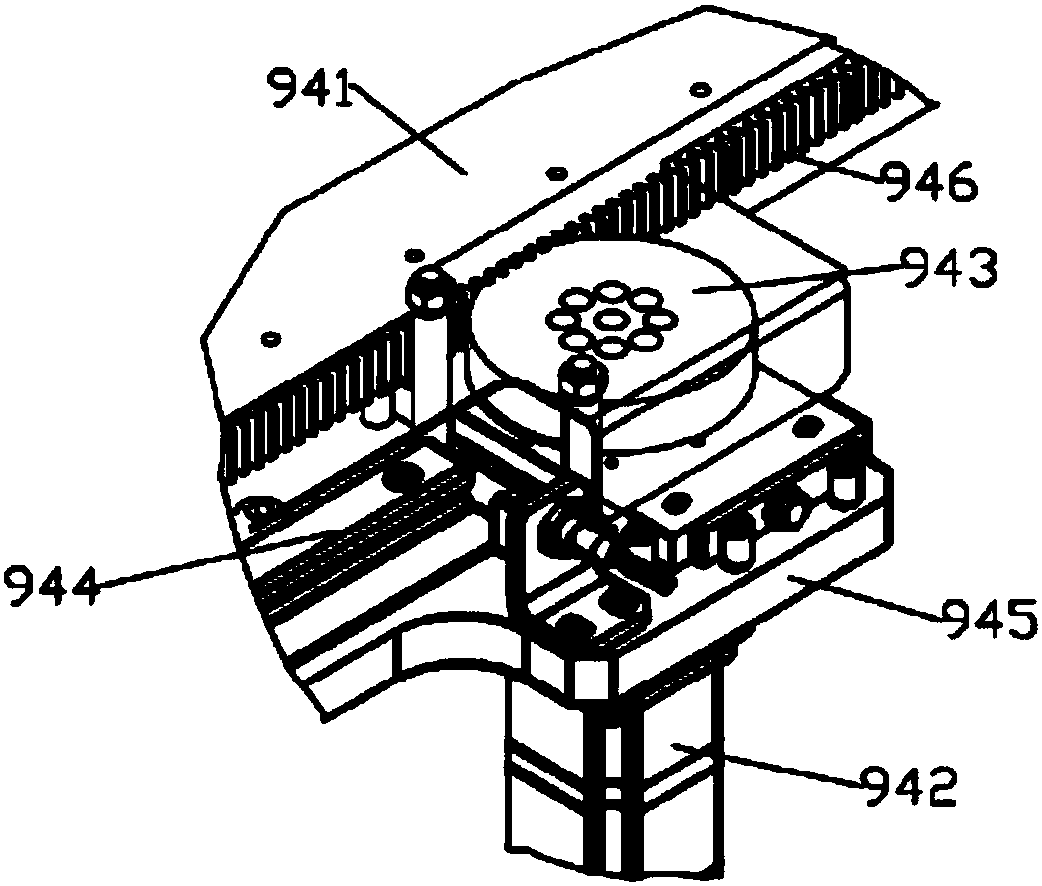

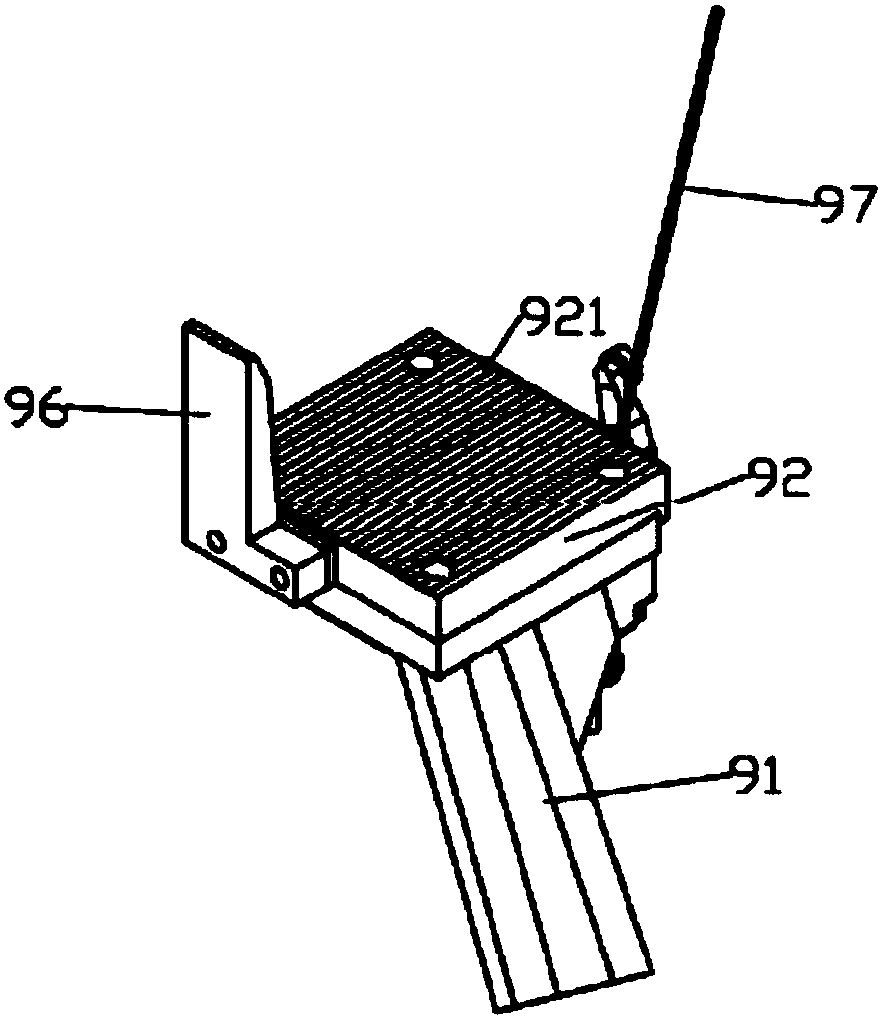

[0031] Figure 1-Figure 8 The diagram shows the following components: first track 1, second track 2, track frame 3, track motor 4, track gear 5, guide rail 6, track rack 7, slider 61, lifting mechanism 8, bracket mechanism 9. Workpiece front bracket mechanism 10, workpiece rear side bracket mechanism 11, first bracket mechanism 101, second bracket mechanism 102, third bracket mechanism 111, fourth bracket mechanism 112, clamping arm 91 , support block 92, swing cylinder 93, traveling mechanism 94, cylinder connector 95, guide block 96, limit rod 97, limit switch 98, angle iron 99, lifting fixed platform 81, lifting movable platform 82, lifting Lifting linear guide rail 83, lifting rack 84, lifting gear 85, lifting motor 86, lifting displacement overtravel protection device 87, locking cylinder 88 of the platform, mounting platform 821 of the workpiece rear side bracket mechanism, workpiece front The installation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com