Hot riveting machining device

A processing device and hot riveting technology, which is applied to household components, household appliances, and other household appliances, etc., can solve problems such as hot riveting time adjustment, improvement of riveting effect, impact on product quality and production efficiency, etc., to achieve stable hot riveting quality, The effect of high heat riveting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

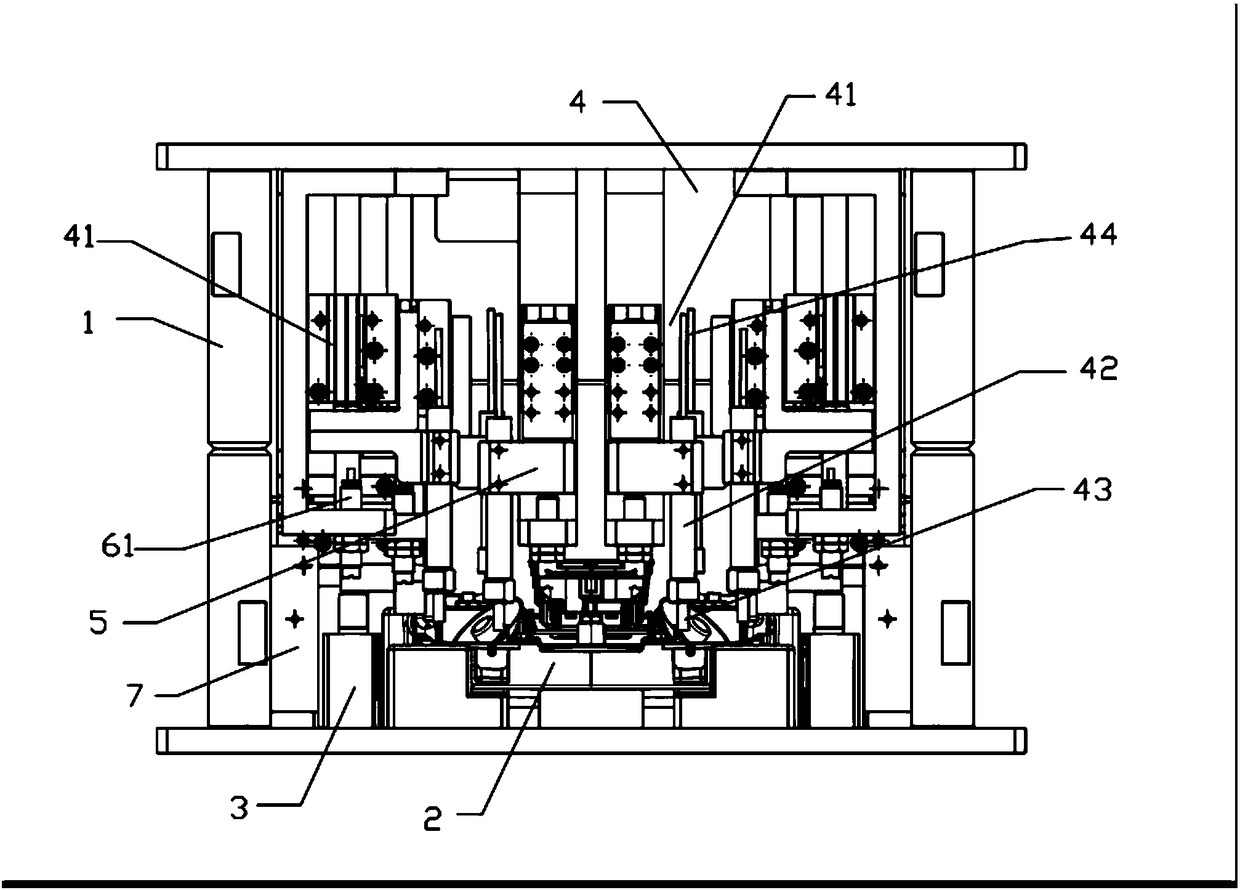

[0017] Such as figure 1 , a workbench 2 is fixed below the frame 1, and the frame 1 above the workbench 2 is correspondingly provided with six sets of hot riveting processing units 4 which can simultaneously hot rivet six riveting points, and the workbench 2 is provided with fastening processing parts The clamping cylinder 3, the frame 1 is provided with a photoelectric switch 7 to control the work of the clamping cylinder 3, each group of hot riveting processing unit 4 includes a hot riveting cylinder 41 arranged on the frame, and the hot riveting cylinder 41 passes through the connecting block 5 The heating pipe 42 with the hot riveting head 43 facing the direction of the workbench 2 is connected at the end. Each hot riveting cylinder 41 corresponds to a limit buffer 61 which limits it and is arranged on the frame. The heating pipe 42 is connected with a temperature sensing line 44 connected with a temperature control device. The temperature of the heating tube and the tre...

specific Embodiment approach 2

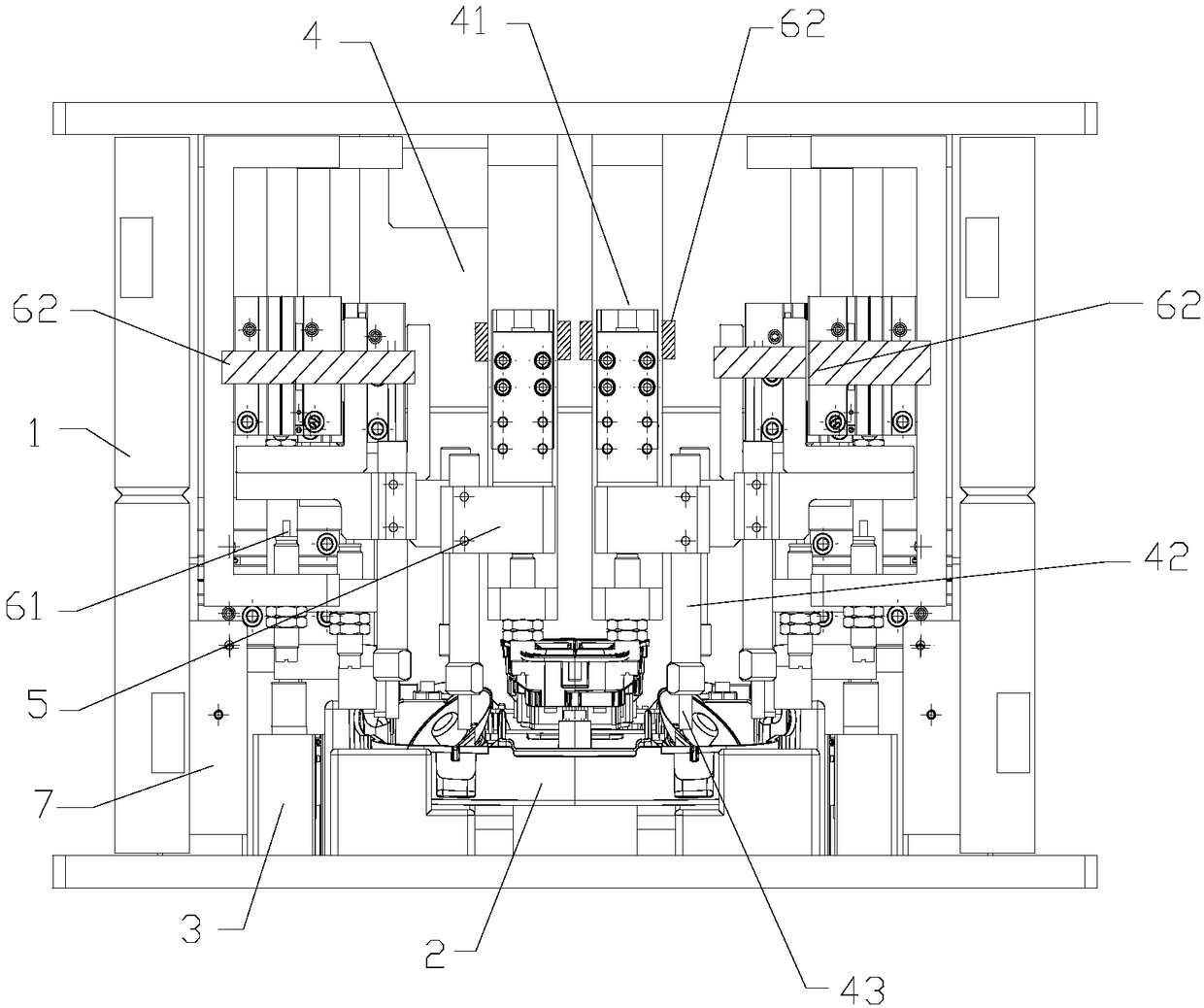

[0018] Such as figure 2 As shown, this embodiment and figure 1 The differences in the shown methods are: first, the heating tubes 42 of the six groups of hot riveting processing units 4 are respectively movably connected with the corresponding connecting blocks 5 . In this way, each group of heating tubes 42 (hot riveting heads 43) can act independently, except that they can be lifted and lowered independently, and the heating tubes can also move horizontally through the movable connection with the connecting block 5, so that In the case that the workpiece switch is complicated or the size of the workpiece at different riveting points is different, in addition to adjusting the up and down distance of the hot riveting head relative to the riveting point, the position of the corresponding workpiece riveting point under the hot riveting head can also be adjusted to ensure The riveting effect of the riveting points at the workpieces of different shapes and sizes at different pos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com