Motorcycle part welding tool fixture

A technology for welding fixtures and parts, applied in manufacturing tools, welding equipment, auxiliary welding equipment, etc., can solve the problems of restricting production efficiency, easy accumulation of waste, inaccurate positioning, etc. Yield and yield effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

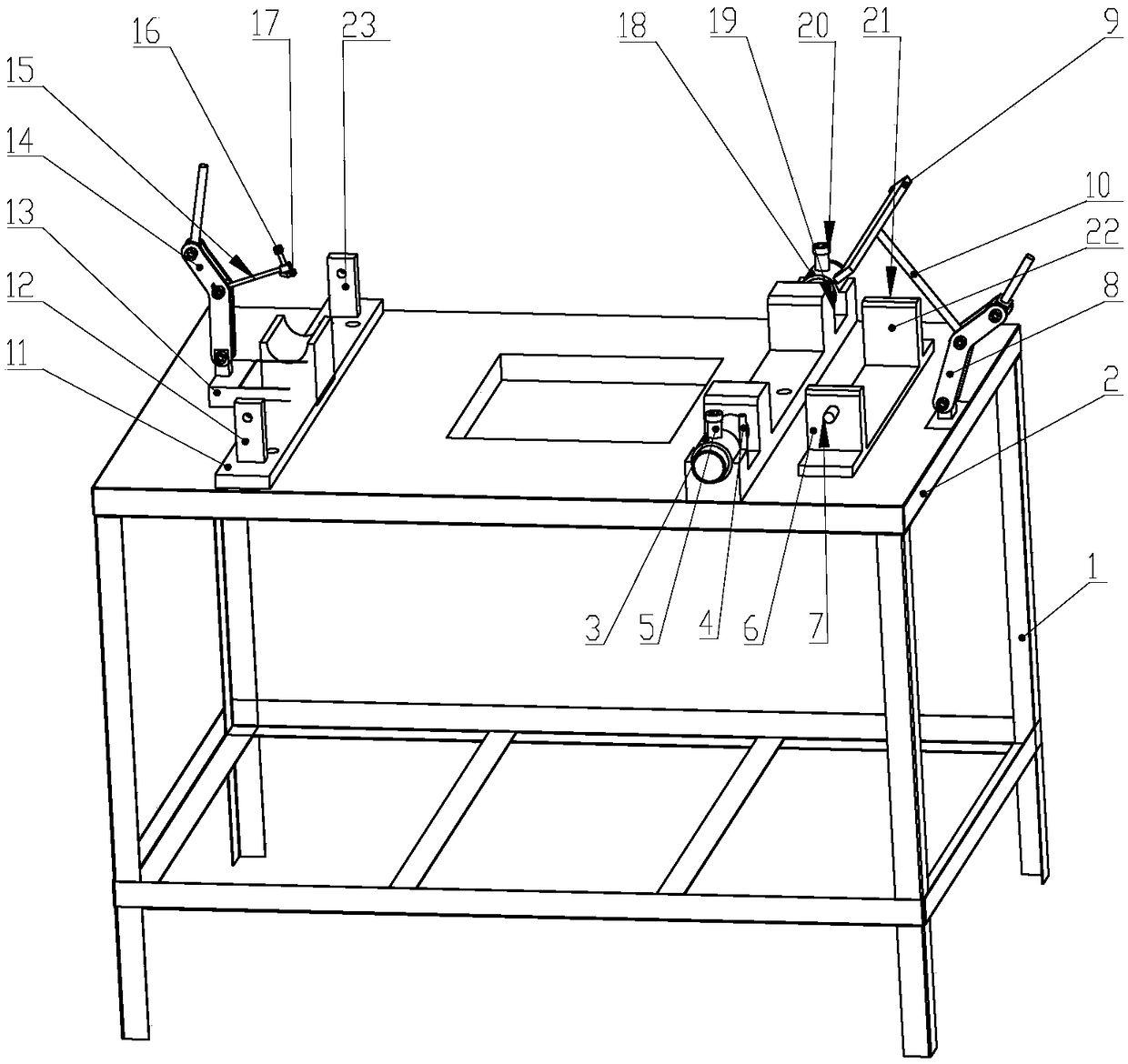

[0012] Such as figure 1 As shown, a welding fixture for motorcycle parts includes a bracket 1, and the bracket 1 is placed on a workbench 2 for installing various components. The middle part of the workbench 2 is empty and cylinders are installed at both ends Adjustable first limiter 3 and second limiter 18, the adjustable first limiter 3 and second limiter 18 are equipped with first adjustment rod 4 and second adjustment rod 19, The first stopper 3 and the second stopper 18 can be adjusted, and the first stopper 3 and the second stopper can be adjusted by rotating the first locking screw 5 and the second locking screw 20 on the top. The right side of 18 is the first right limit plate 6 and the second right limit plate 22, and the first limit pin 7 and the second limit pin 7 are installed on both sides of the first right limit plate 6 and the second right limit plate 22. Limit pin 21, the first limit pin 7 and the second limit pin 21 are used to limit the position of the work...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com