Anti-skid mistake-proof automobile part spot welding clamp

An auto parts, error-proofing technology, applied in manufacturing tools, welding equipment, auxiliary welding equipment, etc., can solve the problems of easily damaged parts surface, affecting welding effect, easy sliding, etc., to achieve the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

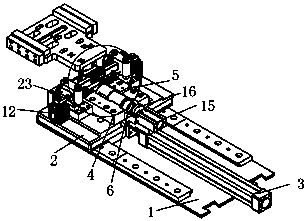

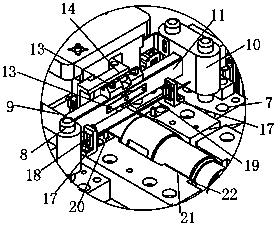

[0012] Combine below figure 1 and figure 2 Specific description embodiment:

[0013] The spot welding fixture for auto parts includes a chassis 1, a workbench 2 is slidably arranged on the chassis 1, the workbench 2 is connected with a workbench cylinder 3, and a left splint 4 and a The right splint 5, the trough 6 is formed between the left splint 4 and the right splint 5, and a guide plate 7 is arranged on one side of the left splint 4 and the right splint 5 on the described workbench 2, and on the guide plate 7 A guide column 8 is provided; an error-proofing plate 9 is arranged above the trough 6 on the workbench 2, and the error-proofing plate 9 includes sliding sleeves 10 located at both ends, and an error-proofing bridge 11 connecting the two sliding sleeves 10, Two sliding sleeves 10 are slidably arranged on the guide column 8 respectively. The sliding sleeves 10 are connected with an error-proofing cylinder 12, and sensors 13 are respectively arranged at the top and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com