Production method and line for female hygiene care products

A production method and production line technology, applied in the field of health care products production, can solve problems such as insufficient production capacity, low production efficiency, and unsatisfactory performance, and achieve the effects of high fit, reduced labor costs, and elimination of uncertainty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

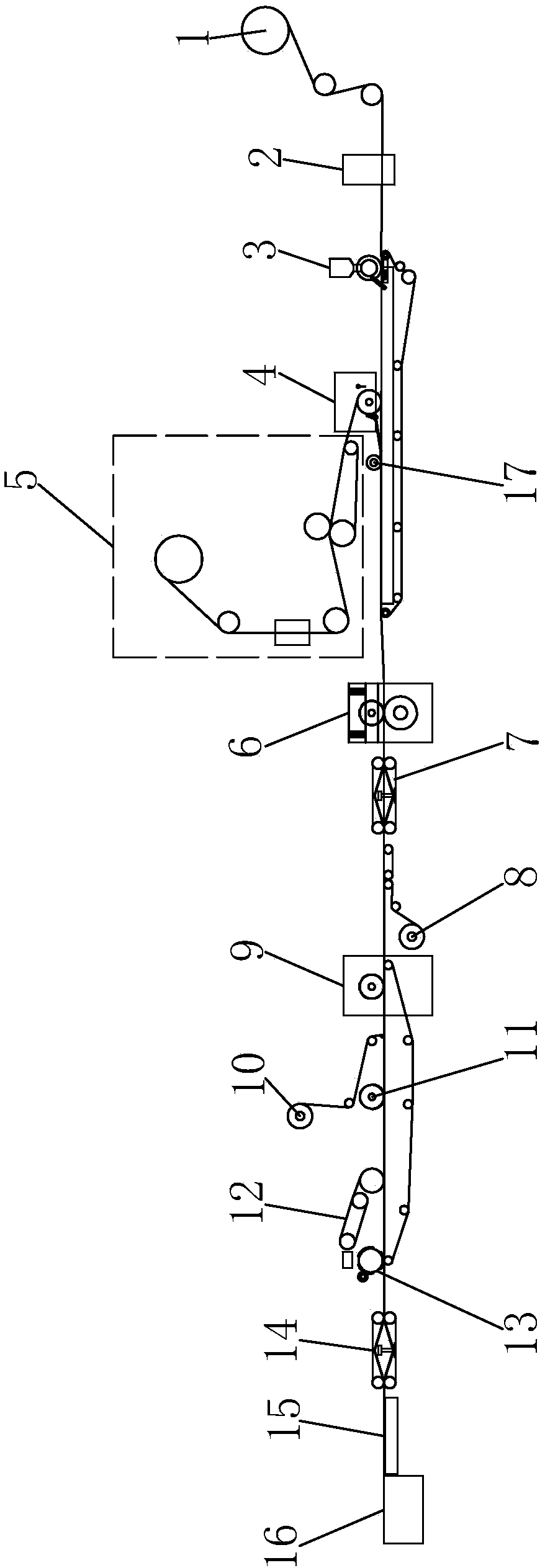

[0032] Now, the present invention will be further described in detail in conjunction with the accompanying drawings and preferred embodiments.

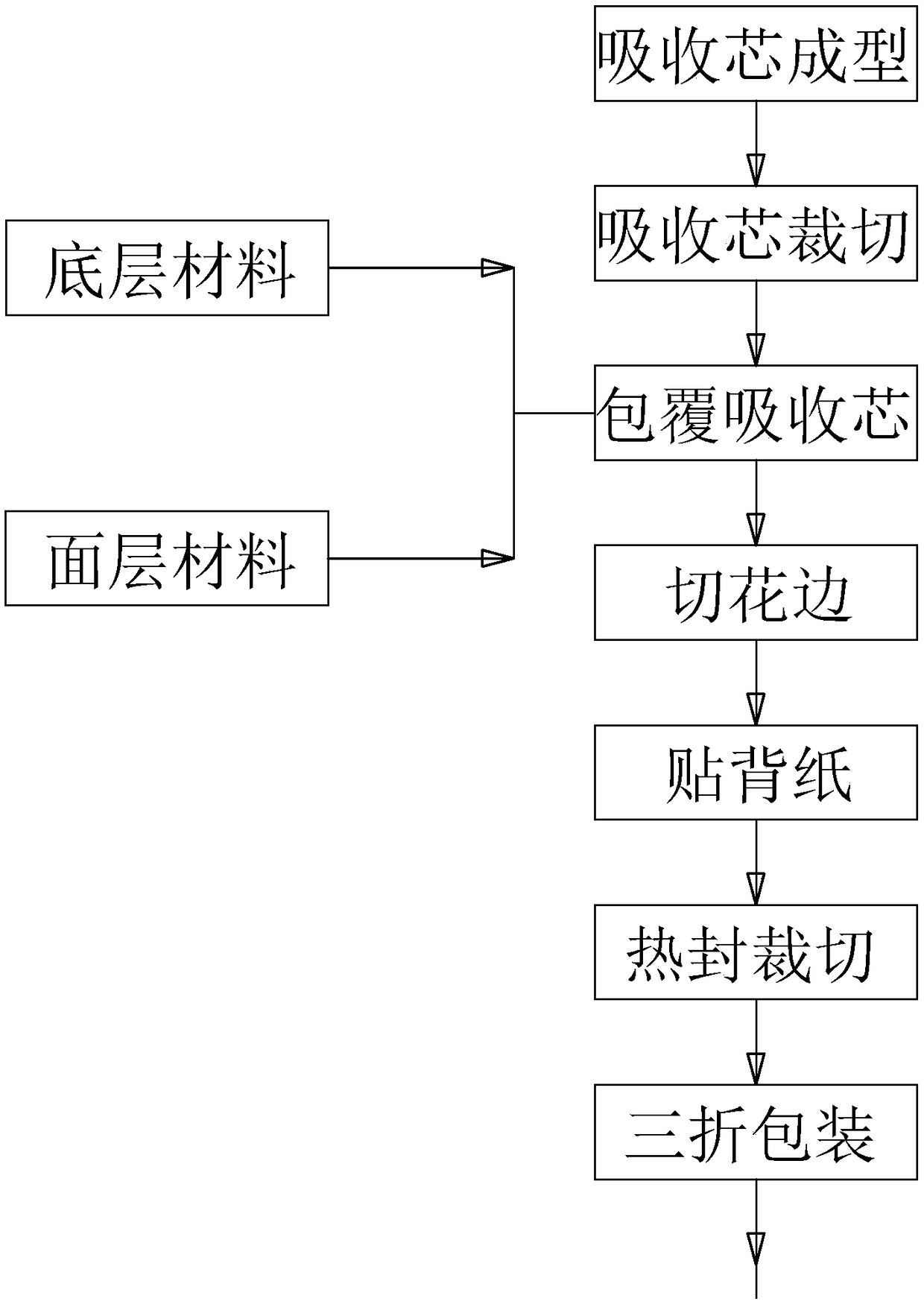

[0033] A production method of female physiological products, such as figure 1 shown, including the following steps:

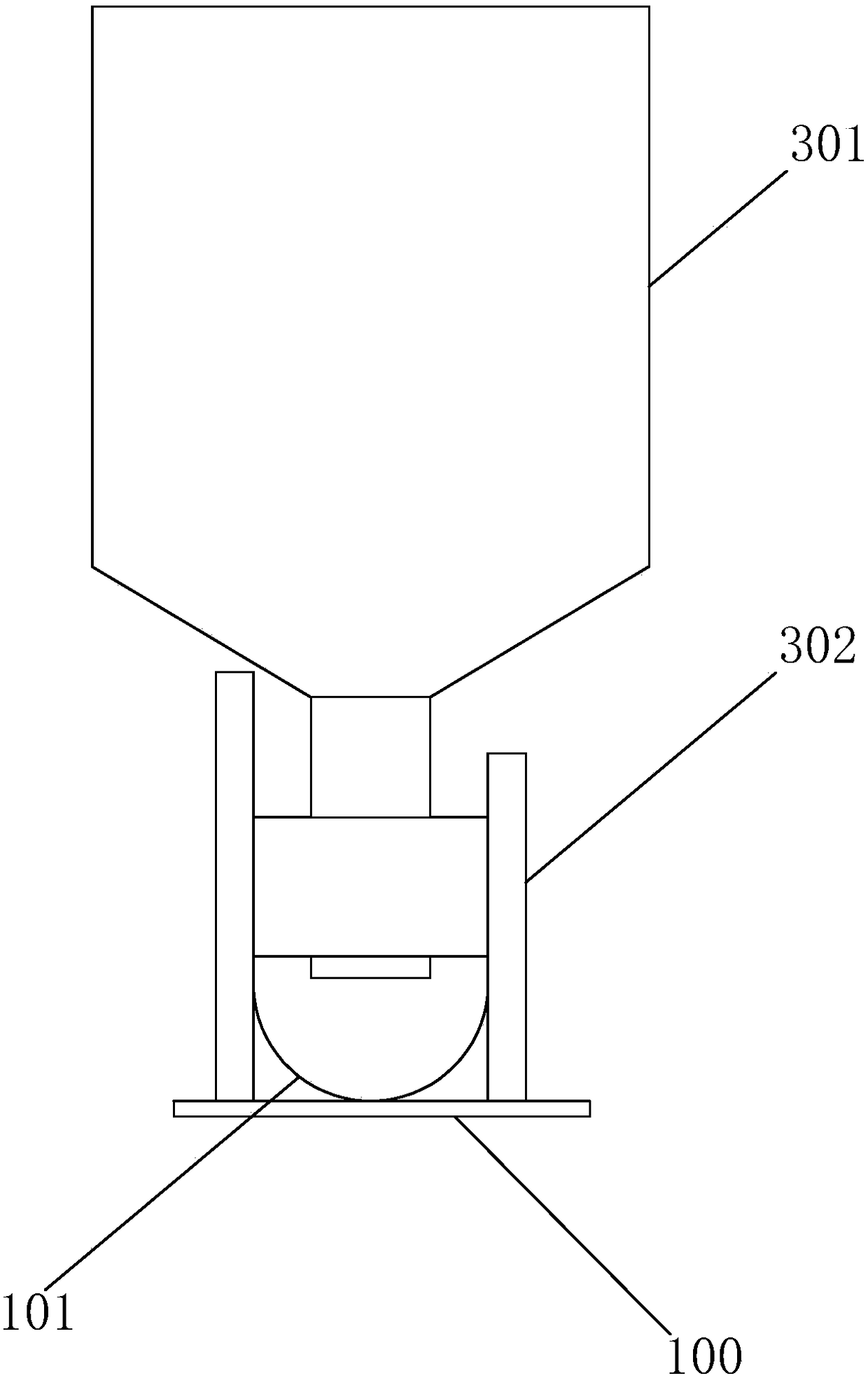

[0034] A. Absorbent core forming: flatten the wide paper 101, so that the wide paper 101 is absorbed on the conveying line 100, and the wide paper 101 is bent into a "U" shape by the fluff pulp injection mechanism 3, and the "U" of the wide paper 101 The fluff pulp is injected into the groove, and then the wide paper 101 is flattened, so that the wide paper 101 is absorbed on the conveying line 100. After the narrow paper 102 is cut into individual pieces, the narrow paper 102 is covered on the fluff pulp.

[0035] B. Absorbent core cutting: compact the fluff pulp covered by the narrow paper 102, and at the same time, the fluff pulp is squeezed and penetrated to the entire coverage of the narrow paper 102, and the edg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com