Vehicle variable cross section plate spring rolling mill computer control system

A control system and computer technology, applied in the field of machinery, can solve the problems of large size, low precision and large expansion of energy-consuming equipment, and achieve the effects of strong servo tracking ability, insensitive to changes in system parameters, and simple algorithm

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with drawings and embodiments.

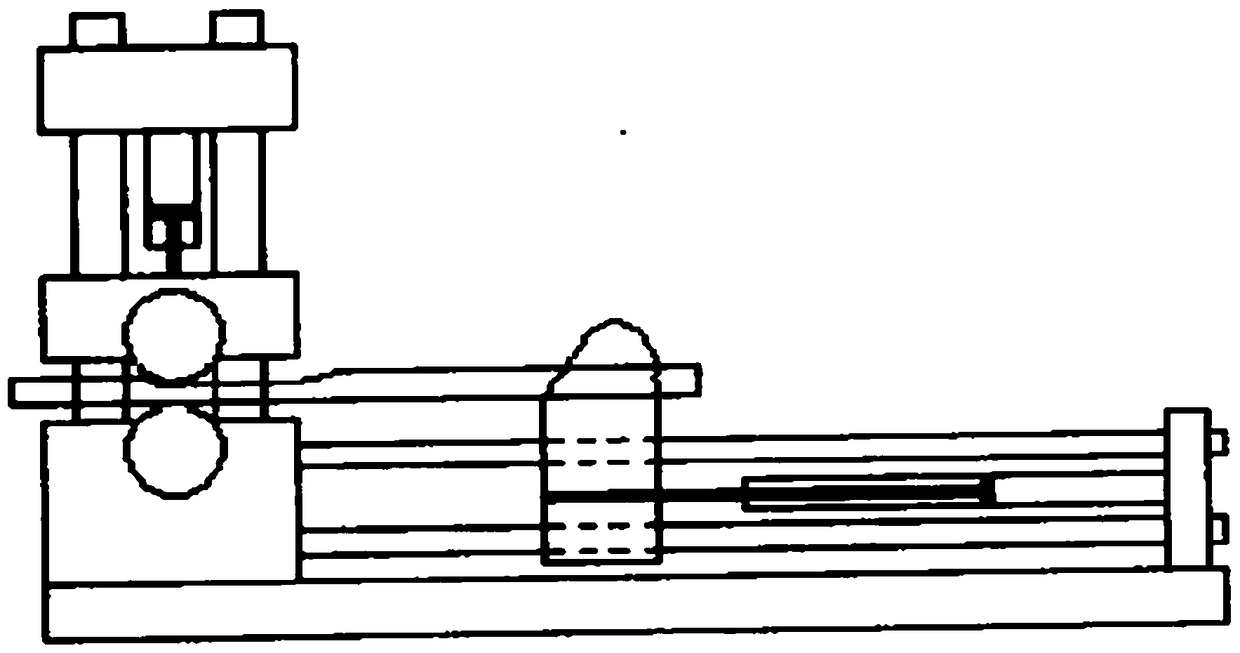

[0014] Such as figure 1 , the mechanical structure of the rolling mill is composed of a steel frame support, a roll driving mechanism and a pulling mechanism. The roll is driven by a hydraulic motor, and the upper roll is controlled by a servo cylinder to move up and down. The pulling mechanism is composed of a guide column and a hydraulic clamping device. The horizontal servo cylinder is controlled to move in the horizontal direction. The pressure is stabilized by the hydraulic accumulator, and the output torque of the hydraulic motor is controlled by a proportional pressure reducing valve. The displacement and speed in the X and Y directions are detected by two rotary encoders.

[0015] Such as figure 2 , The controlled quantity of rolling mill control system can be divided into analog quantity part and switch quantity part. The analog part consists of four circu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com