Shift lever device

A shift lever and gear position technology, which is applied in transmission control, components with teeth, belts/chains/gears, etc., can solve the problems of low degree of freedom and dependence on sensor configuration, and achieve the goal of improving configuration freedom Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach >

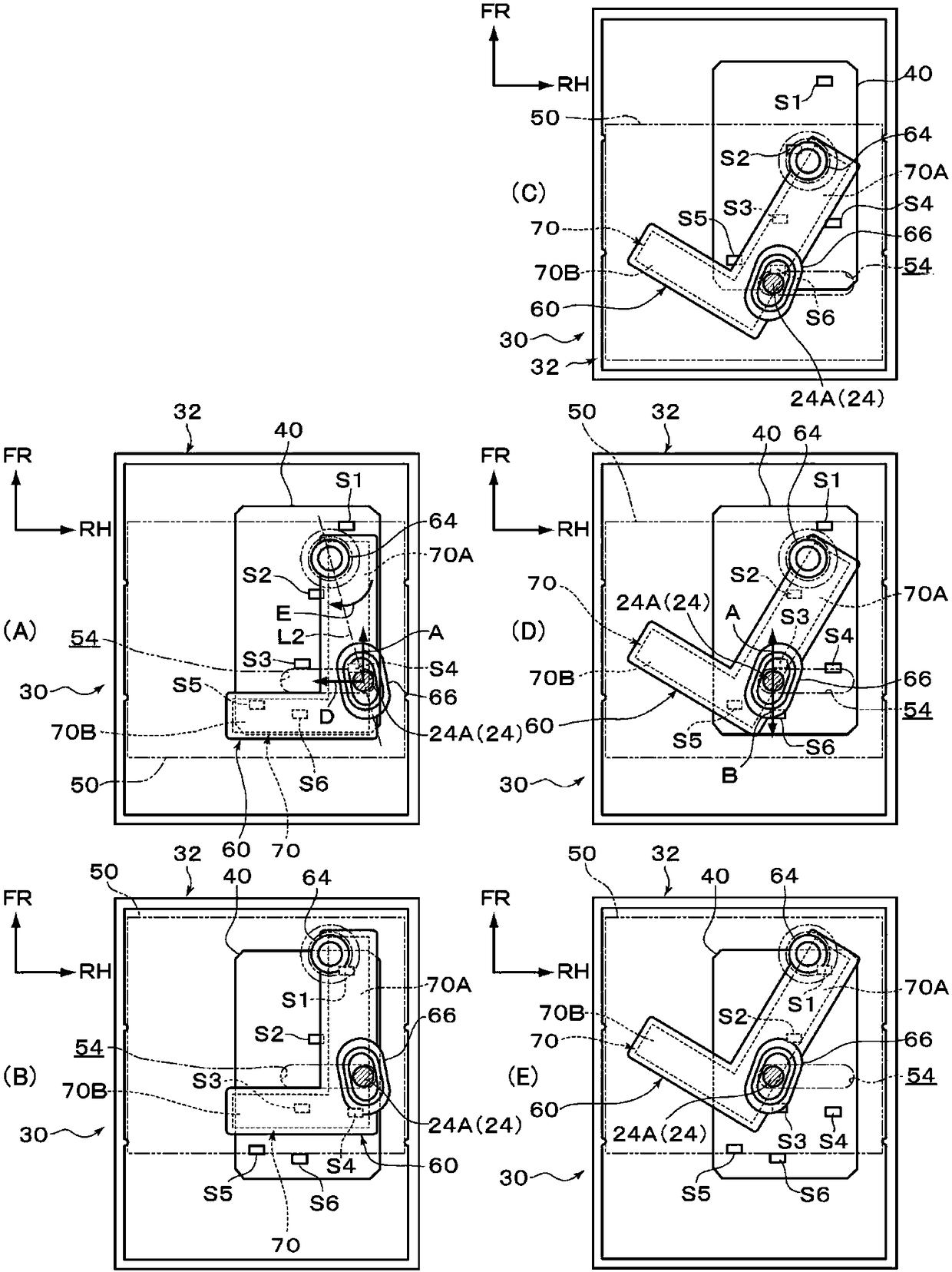

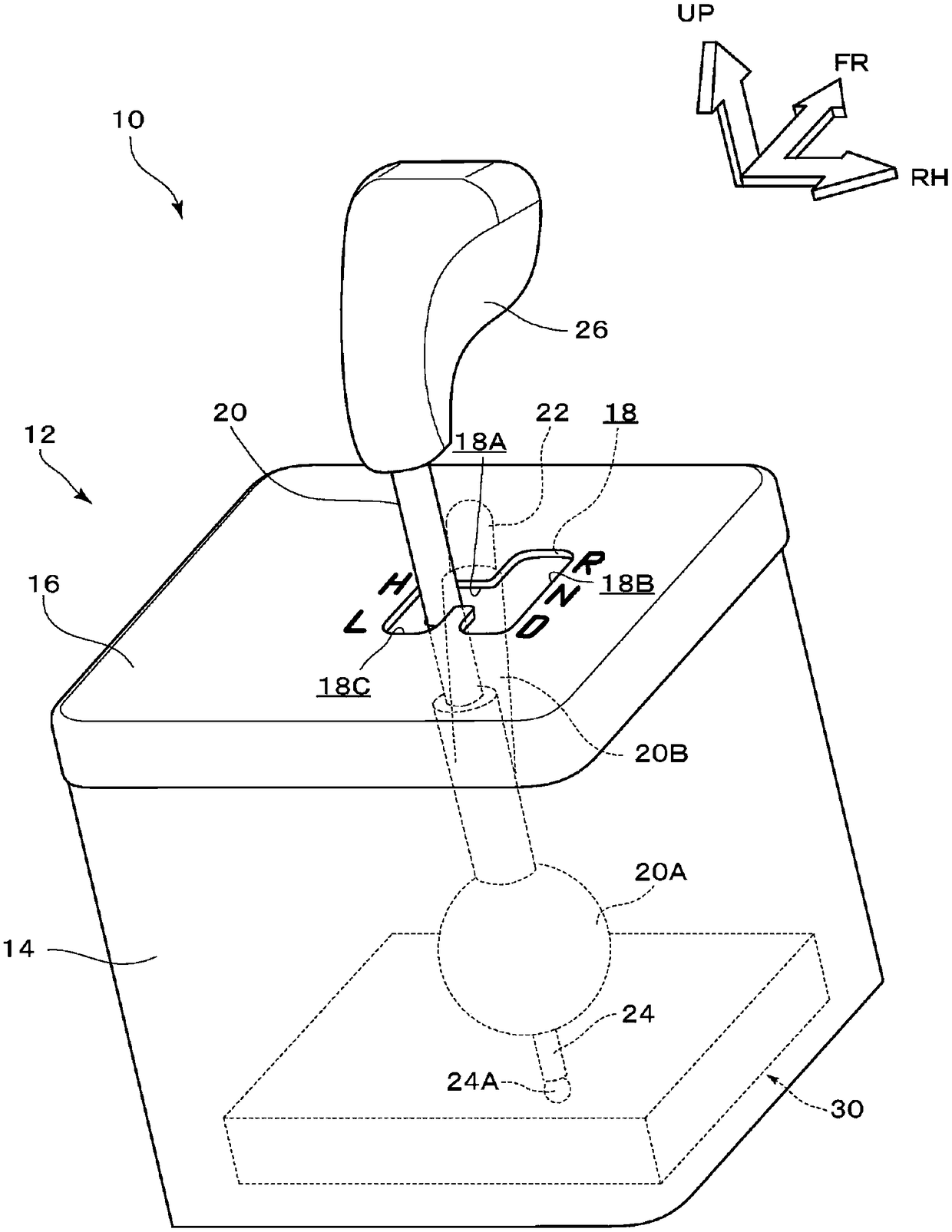

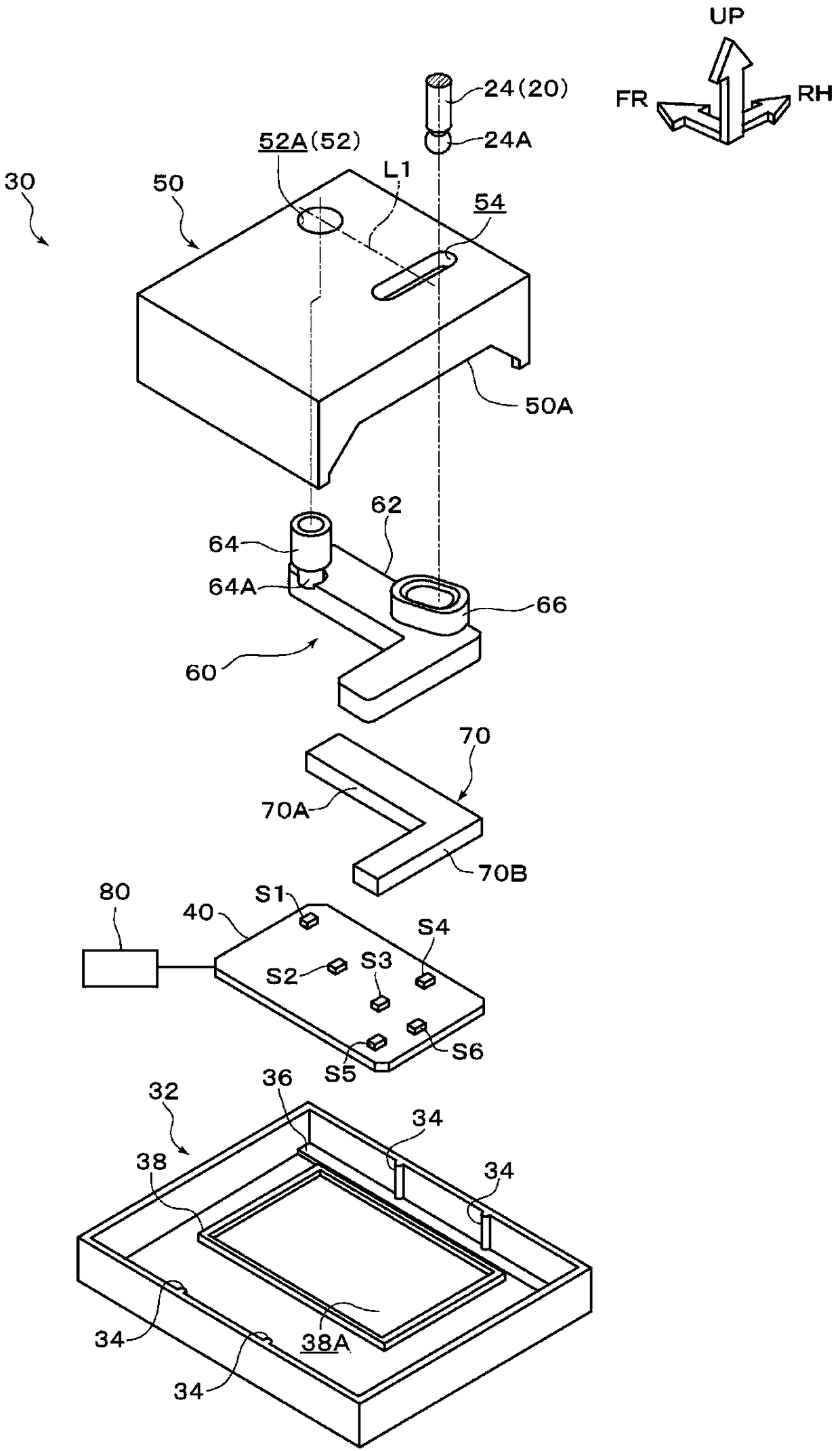

[0103] Below, according to Figure 1 to Figure 5 The shift lever device 10 according to the first embodiment will be described. In addition, in the drawings, arrow UP, arrow FR, and arrow RH indicated as appropriate indicate the upper side, the front side, and the right side (one side in the width direction) of the shift lever device 10 . In addition, the directions of up and down, front and rear, and left and right used in the following description mean up and down, front and rear, and left and right of the shift lever device 10 unless otherwise specified.

[0104] Such as figure 2 As shown, the shift lever device 10 is composed of: a housing 12 , a shift lever 20 , and a gear detection mechanism 30 . Next, each configuration of the shift lever device 10 will be described.

[0105] (about the case)

[0106] The housing 12 constitutes a frame of the shift lever device 10 and is formed in a substantially rectangular parallelepiped box shape, and is installed on a center co...

no. 2 approach >

[0151] Below, according to Figure 6 ~ Figure 9 The shift lever device 100 of the second embodiment will be described. The second embodiment has the same configuration as the shift lever device 10 of the first embodiment except for the shift position detection mechanism 130 in the shift lever device 100 . Next, the structure of the gear detection mechanism 130 will be described. In addition, in the following description, the same code|symbol is attached|subjected to the component comprised similarly to the shift lever apparatus 10 of 1st Embodiment. In addition, in the following description, unless otherwise specified, the state in which the shift lever 20 is arrange|positioned at the "H" range is demonstrated.

[0152] Such as Image 6 and Figure 7 As shown, the gear detection mechanism 130 is composed of: a housing 132 , a base plate 140 , a slider 150 , a bracket 160 , a magnet 170 as a “detected object”, and a connecting rod 190 .

[0153]The casing 132 has the same ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com