Convenient welding device

A welding device and a convenient technology, applied in the parts, auxiliary devices, coupling devices and other directions of the connecting device, can solve the problems of shortened service life of the welding machine, electric shock accidents of staff, complicated structure of power supply equipment, etc., and achieve safe and stable power supply. , The effect of stable and safe power supply, safe and reliable power supply

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

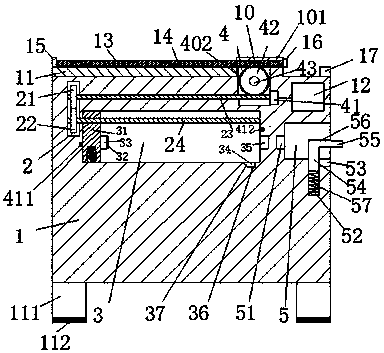

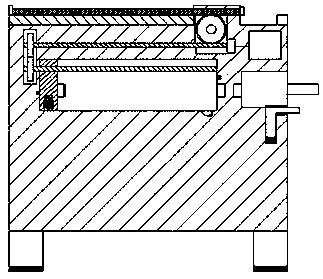

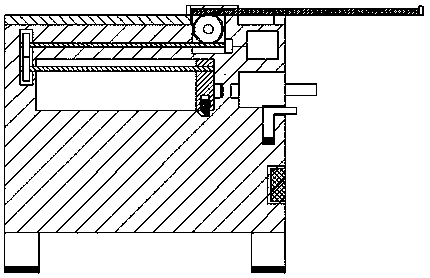

[0026] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

[0027] refer to Figure 1-6A convenient welding device shown includes a frame body 1 and an electrical connector connected to the welding machine. The bottom end of the frame body 1 is provided with a leg 111, and the bottom of the leg 111 is fixedly equipped with a foot pad 112. The top of the frame body 1 is provided with a convex portion 10, the frame body 1 is provided with a first sliding groove 3 extending left and right, and the frame body 1 is provided with a tooth groove 2 at the left end of the first sliding groove 3, so The frame body 1 is also provided with a turbine groove 4 that extends upwards into the convex portion 10, and the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com